Choosing the right geocell can be confusing when faced with different technical specs. Making the wrong choice can lead to a weak foundation, project failure, and wasted money.

The welding distance directly determines the geocell's cell size. A shorter distance creates smaller, tighter cells that confine soil more effectively. This increases the structure's overall stiffness and dramatically improves how it spreads loads across the ground, boosting the system's performance and stability.

So, the secret to a geocell's strength lies in how tightly it holds the soil together. This single specification is one of the most critical factors in designing a stable and long-lasting foundation. But how does this really work in practice, and how can you use this knowledge to specify the right product and even save money on your next project? Let's break it down based on my experience exporting these materials worldwide.

How does welding distance influence the internal cell geometry and overall structural rigidity of a geocell panel?

You've probably seen specs like "330 mm vs. 660 mm welding distance" on a data sheet. This is more than just a number; it directly dictates the final strength of the geocell panel.

A smaller welding distance creates smaller but deeper cells when the panel is expanded. This increases the number of cells per square meter. The result is a denser, more interconnected structure that acts like a semi-rigid slab, significantly improving its overall rigidity.

The welding distance is the fundamental geometric factor that controls geocell performance. It defines the size of the cell aperture once the panel is stretched out on-site. Smaller weld spacing means you get smaller individual cells, but more of them in the same area. This creates a much denser and more robust structure. From my work with engineering contractors, I've seen how this seemingly small detail makes a huge difference. The geocell system transforms from a collection of individual plastic strips into a single, cohesive mat. This interconnectedness is what provides the powerful structural rigidity needed to support heavy loads.

Here is a quick reference table I often share with clients to clarify this relationship:

| Welding Distance | Expanded Cell Width (Approx.) | Cell Density (per m²) | Confinement Strength |

|---|---|---|---|

| 330 mm | 250 mm | ~35 | Very High |

| 356 mm | 260 mm | ~31 | High (Standard) |

| 445 mm | 320 mm | ~22 | Médio |

| 660 mm | 470 mm | ~12 | Low |

What relationship exists between welding distance and a geocell’s ability to confine soil and resist deformation under load?

Your soil base keeps failing under load, causing ruts and uneven surfaces. You know geocells can help, but you need to understand how to maximize their effect to lock your soil in place.

The relationship is direct: smaller welding distances provide stronger lateral confinement. When a load pushes down, the smaller cells physically prevent the soil from bulging sideways. This powerful resistance to deformation is the core mechanism that allows geocells to stabilize weak ground effectively.

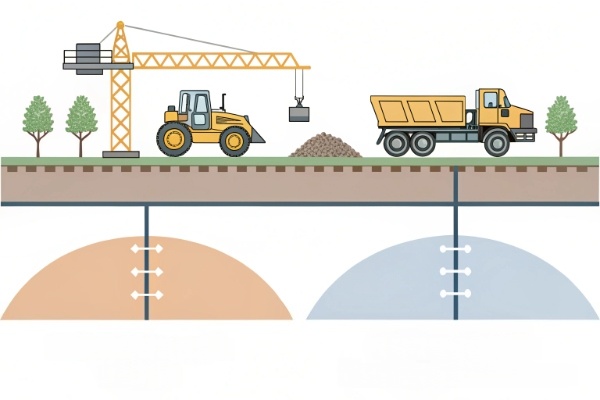

This is where the real magic of geocells happens. When you apply a vertical load, like from a truck wheel, the soil inside a geocell naturally wants to push outwards. The cell walls stop this movement, creating a counter-force that confines the soil. This is known as the "Lateral Confinement Effect."

A smaller cell, created by a shorter welding distance, leaves very little room for the soil to move. The confinement is strong and uniform. In contrast, a large cell allows the soil to shift and bulge more before the walls engage, resulting in weaker confinement. This increased confinement doesn't just hold the soil; it fundamentally changes its behavior. It increases the soil's effective stiffness and creates what engineers call an "apparent cohesion." This turns loose, granular material into a stable composite layer that can handle much higher loads without deforming. In lab tests and real-world projects, we see stiffness improvements of up to 2.2 times by simply using a smaller welding distance.

In which engineering applications does selecting an appropriate welding distance significantly improve load-distribution performance?

You're designing a project, but using the same geocell for every application feels wrong. Over-engineering costs money, while under-engineering leads to failure. How do you choose the correct specification?

In heavy-duty applications like port container yards, mine haul roads, and airport taxiways, a smaller welding distance is critical. It distributes massive point loads over a wider area, reducing stress on the soft subgrade below and preventing costly rutting and settlement.

The choice of welding distance should always match the load requirements of the project. I've supplied geocells for everything from garden paths to military airfields, and the specifications are never the same. For heavy-load scenarios, the geocell system must act like a rigid mattress, spreading concentrated stress from tires or equipment feet over the largest possible area. A smaller welding distance (like 330 mm) creates the dense cell structure needed to achieve this. Studies have shown that this can reduce peak pressure on the subgrade by 30-50%. For standard applications like residential driveways or access roads, a 356 mm welding distance often provides the perfect balance of performance and cost. For lighter applications like slope protection or landscaping, a larger distance (445 mm or more) can be a perfectly suitable and economical choice since the loads are much lower.

Here's a simple guide I use:

- Heavy Loads (Ports, Mining): 330 mm for maximum load distribution.

- Medium Loads (Roads, Parking Lots): 330 mm to 356 mm for the best cost-performance ratio.

- Light Loads (Slopes, Walkways): 356 mm to 445 mm where confinement is less critical.

How can I evaluate project requirements to determine the optimal welding distance for reliable geocell reinforcement?

You want to optimize your project for both cost and performance. Simply choosing the strongest geocell isn't always the smartest financial move. You need a practical way to decide without guesswork.

Balance three factors: subgrade strength (often measured in CBR), the type and weight of expected loads, and your budget. For soft ground or heavy, dynamic traffic, a smaller welding distance (e.g., 330 mm) offers the best long-term reliability and performance.

One of the most valuable insights I share with clients is the relationship between welding distance and geocell height. Many people assume a taller geocell is always better, but that's not the whole story. You can often achieve similar, or even better, performance with a shorter geocell that has a smaller welding distance. This can lead to significant cost savings. For example, a project might call for a 150 mm tall geocell with a standard 356 mm welding distance. However, my experience and test data show that a 100 mm tall geocell with a smaller 330 mm welding distance can provide equivalent bearing capacity.

Let's look at a performance comparison I often use:

| Configuration (Weld Distance / Height) | Bearing Capacity Improvement | Custo relativo | Takeaway |

|---|---|---|---|

| 356 mm / 150 mm (Standard) | 1.3x – 1.5x | 1.4x | Good performance, but higher material cost. |

| 330 mm / 100 mm (Optimized) | 1.4x – 1.7x | 1.15x | Similar performance for a much lower cost. |

By choosing the optimized configuration, you use less raw material, which lowers the product cost and reduces shipping volume. This is a smart engineering trade-off that saves money without sacrificing performance.

Conclusão

Choosing the right geocell welding distance is key for project success. Smaller distances provide stronger soil confinement and better load distribution, often allowing for a more cost-effective design with a shorter geocell.