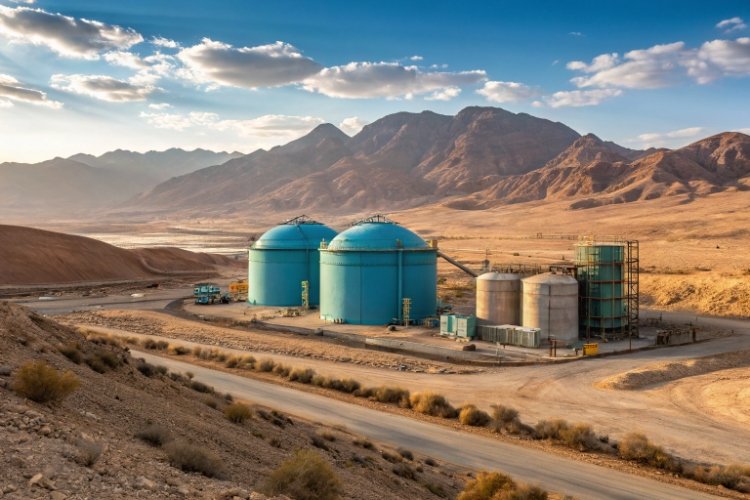

A leak in a cyanide heap leach pad is an environmental and financial disaster. Choosing the wrong liner material puts your entire mining operation, your investment, and your reputation at risk.

Yes, HDPE has excellent direct chemical resistance to cyanide. The primary long-term concern isn't the cyanide itself, but the combination of high heat and alkaline pH (9.5-11), which accelerates the depletion of the liner's protective antioxidants, impacting its service life.

From my experience shipping liners to gold mines globally, the question isn't whether HDPE can handle cyanide—it can, and it's the industry standard for this reason. The real, practical question is about service life. The degradation of the liner isn't a direct chemical attack, but a slower, more complex process driven by the entire heap leach environment. Understanding this is key to selecting a liner that will last for decades.

How does cyanide exposure affect HDPE geomembranes?

You might imagine the cyanide solution aggressively eating away at the plastic liner. This common misconception can cause you to worry about the wrong failure modes and overlook the real threat.

Cyanide solutions don’t directly dissolve or corrode the HDPE polymer. Instead, the highly alkaline and often hot environment of heap leaching accelerates the consumption of the antioxidant additives within the geomembrane, which is the first aggressive stage of the material's long-term aging.

The failure process of an HDPE liner in a heap leach pad is well-understood and happens in predictable stages. It's less like a chemical burn and more like a slow exhaustion of the material's defenses.

Stage A: Antioxidant Depletion

High-quality HDPE geomembranes contain a package of antioxidant additives. Their job is to sacrifice themselves to protect the actual HDPE polymer chains from damage caused by heat and oxidation. The hot, alkaline environment of a cyanide heap leach pad creates ideal conditions for these protective antioxidants to be consumed very quickly. This is the first and most critical phase of aging.

Stage B & C: Polymer Degradation

Once the antioxidants are gone, the HDPE polymer itself is vulnerable. The polymer chains begin to break down through oxidation. This process makes the material more brittle and significantly reduces its ability to resist stress cracking. Over time, the liner loses its flexibility and can crack under the immense weight of the ore pile, leading to leaks.

The Surprising Role of Other Chemicals

Recent long-term studies have shown a surprising fact. One major study submerged HDPE in various leachates for 36 months and found that a neutral pH solution containing arsenic and chlorides caused faster mechanical degradation than the high-pH cyanide solution. This proves it is the entire chemical cocktail—including salts and heavy metals—combined with heat, not just the cyanide, that determines the liner's service life.

What chemical resistance properties make HDPE suitable for heap leaching?

You need to justify your material choice to project managers, engineers, and regulators. Simply saying "it's the standard" isn't enough; you need to explain why it works.

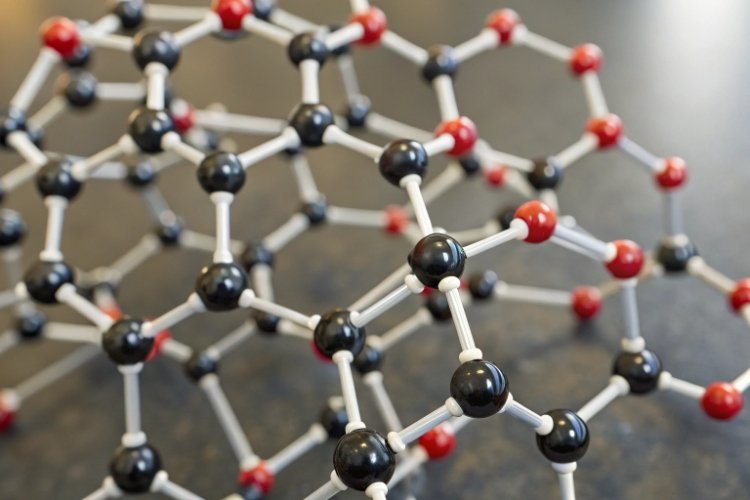

HDPE’s suitability comes from its highly crystalline, non-polar molecular structure. This dense structure provides a formidable physical barrier and makes it inherently resistant to a wide range of chemicals, allowing it to remain stable across the entire pH range of heap leaching.

The secret to HDPE's success is built into its very chemistry and physical form. It's not just a plastic sheet; it's a highly engineered barrier material.

| Propriedade | Benefit for Heap Leaching |

|---|---|

| Crystalline Structure | Acts as a physical barrier against chemical ingress. |

| Non-Polar Nature | Lacks reaction sites for many chemical compounds. |

| Wide pH Resistance (1-14) | Stays stable in the highly alkaline cyanide solutions. |

| Extremely Low Permeability | Prevents leakage of toxic leachate into the environment. |

Crystalline Molecular Structure

Imagine trying to get through a tightly packed brick wall versus a loose pile of rubble. The molecules in HDPE are like the brick wall—they are packed together in a tight, crystalline formation. This makes it physically difficult for chemical molecules like cyanide to penetrate the liner.

Wide pH Range Resistance

HDPE is stable across an incredible pH range, from 1 to 14. This is a critical feature for gold mining, where the leaching process is maintained at a high alkaline pH of 9.5 to 11 to keep the cyanide in a stable solution. HDPE is completely unfazed by these conditions.

Under which heap leaching conditions is HDPE performance most reliable?

You have a heap leach project, but the site conditions are harsh, with high ambient temperatures and intense sunlight. You know this will affect the liner's lifespan, but by how much?

HDPE performance is most reliable in low-to-moderate temperature heaps (below 60°C / 140°F). Its service life is severely shortened in high-temperature heaps (above 85°C / 185°F) and when subjected to high installation stress or mechanical damage during ore placement.

While HDPE is robust, its lifespan is not infinite and is highly dependent on the operating conditions. Managing these factors is just as important as choosing the right material.

Temperature is the Primary Factor

Heat is the single greatest accelerator of antioxidant depletion. The reaction rate can double with every 10°C increase in temperature. This means a liner that might last 50 years at 40°C could see its antioxidant package depleted in just a few years at 85°C. For this reason, controlling leachate temperature is critical for extending the life of the geomembrane.

Mechanical Stress and Protection

A liner that is stretched tight during installation is already under stress. This makes it far more susceptible to stress cracking as the polymer ages. Proper installation that avoids high tensile stress is crucial. Furthermore, the liner must be protected from puncture by a cushioning geotextile layer placed between it and the sharp aggregate or ore.

UV Exposure

Any part of the liner that is exposed to sunlight, such as in anchor trenches, must be protected from UV radiation. This is why all high-quality HDPE geomembranes contain 2-3% finely dispersed carbon black, which acts as a powerful UV stabilizer, preventing the plastic from becoming brittle in the sun.

What specifications should be checked for cyanide-resistant HDPE liners?

You're ready to create a technical specification for a purchase order. If you leave out key parameters or only specify thickness, you might receive a low-quality product that fails prematurely.

Look beyond just thickness. Specify a thickness of 1.5mm to 2.0mm, but most importantly, demand a high value for Oxidation Induction Time (OIT), especially High-Pressure OIT (HP-OIT). This is the direct measure of the liner's resilience to long-term aging.

As a supplier, I always guide my mining clients to focus on the performance metrics that predict long-term life, not just the basic physical properties.

| Specification | Recommended Value | Why It Matters for Heap Leaching |

|---|---|---|

| Grossura | 1.5mm (60 mil) - 2.0mm (80 mil) | Durability; a thicker liner has more antioxidants. |

| High-Pressure OIT | > 2000 minutes (for high-performance resins) | Directly measures long-term thermal stability. |

| Resistência a fissuras por estresse | High performance value per ASTM D5397 | Resists cracking under load and chemical exposure. |

| Carbon Black Content | 2.0% - 3.0% | Provides critical UV protection for exposed areas. |

A 2.0mm liner doesn't just offer better puncture resistance; it contains about 33% more antioxidants than a 1.5mm liner of the same formulation, providing a longer service life in hot conditions. Demanding a high HP-OIT value ensures you are getting a premium resin with an additive package designed specifically for the punishing environment of a heap leach pad.

Conclusão

HDPE effectively resists cyanide, but its true longevity depends on choosing a thick, high-OIT liner and designing the system to manage heat, which is the true driver of aging.