A geomembrane liner is only as strong as its weakest point. While we focus heavily on the integrity of large panels and seams, the point where a pipe penetrates the liner is often the most vulnerable. A failed connection here means a guaranteed leak, defeating the purpose of the entire containment system.

This guide provides a complete overview of the primary methods for creating a permanent, leak-proof seal between a geomembrane and a Polyethylene (PE) pipe. We will cover welding, electrofusion, and mechanical methods, compare their performance, and recommend the best approach for different project types, from landfills to reservoirs.

Before we dive into the "how," let's quickly review "why" this connection is so critical.

Why Geomembranes Must Be Connected to PE Pipes

In almost any containment system, pipes are essential. They serve critical functions like:

- Leachate collection and removal in landfills.

- Gas venting and management.

- Drainage systems for surface water.

- Inlet and outlet pipes for ponds, tanks, and reservoirs.

Each of these pipes must pass through the impermeable geomembrane barrier. The connection must be perfectly sealed to maintain the integrity of the containment system. It must be strong enough to handle mechanical stress and durable enough to last for decades while exposed to chemicals, weather, and ground movement.

Three Primary Methods for Geomemembrane–PE Pipe Connections

There are three main industry-accepted methods for connecting a geomembrane to a PE pipe. The choice depends on the project's requirements for seal integrity, site conditions, and cost.

Hot-Melt Welding: Extrusion and Hot Wedge

This is the most common and reliable method for connecting PE geomembranes to PE pipes. It involves using heat to melt the two materials together, creating a continuous, monolithic bond at the molecular level. The resulting weld is often stronger than the parent material itself.

- Extrusion Welding: In this process, a technician uses a handheld extrusion welder that heats the geomembrane and pipe surfaces while simultaneously laying down a molten bead of PE plastic. This bead fuses the two components together, creating a robust, custom-fitted seal. It's the go-to method for creating "pipe boots"—a detailed collar around the pipe.

- Prefabricated Pipe Boots: To improve efficiency and reliability, prefabricated boots are often used. These are factory-made components with a sleeve sized to the pipe and a wide flange. The sleeve is slipped over the pipe, and the flange is then welded directly to the main geomembrane liner using a hot-wedge or extrusion welder. This reduces complex on-site fabrication work.

This method is standard for high-risk applications like landfills due to its exceptional seal performance.

Electrofusion Method: Using Electrofusion Plates

The electrofusion method uses specialized fittings that have built-in heating coils. An "electrofusion saddle" or plate is placed over the pipe-geomembrane interface. A controlled electrical current is then passed through the coils, generating precise heat that melts and fuses the fitting to both the pipe and the geomembrane.

Advantages:

- High-Quality Seal: Creates a strong, homogenous weld.

- Automated Process: Less dependent on operator skill than manual extrusion welding.

- Weather Independent: The process is controlled and can be performed in a wider range of weather conditions.

Limitations:

- Requires specialized electrofusion fittings and processors.

- The cost of fittings can be higher than for simple extrusion welding.

This method is gaining popularity for its speed and consistency, especially on large projects with many identical penetrations.

Mechanical Connection: Flanges and Clamping Strips

This method does not rely on welding. Instead, it uses mechanical force to compress a gasket between the geomembrane and the pipe, creating a seal. A typical setup consists of two metal rings (flanges) and a set of bolts. The geomembrane is placed over the pipe, a neoprene gasket is added, and the flanges are bolted together, clamping the liner tightly to the pipe.

Suitable Scenarios:

- Connecting to different materials: This is the most universal method and can be used to connect a geomembrane to any pipe material (PE, PVC, steel, concrete).

- Lower-risk applications: Suitable for reservoirs or irrigation ponds where absolute zero-leakage is less critical than in a hazardous waste landfill.

- Temporary installations: Can be disassembled if needed.

The main drawback is that the seal relies on maintaining compression. Bolts may need periodic re-tightening (every 5-10 years), and the gasket can degrade over time.

Comparison of Connection Methods

| Recurso | Hot-Melt Welding | Electrofusion Welding | Mechanical Connection |

|---|---|---|---|

| Seal Performance | Excellent. Monolithic bond, often stronger than parent material. The most reliable for long-term containment. | Excellent. Creates a homogenous, highly reliable welded connection with repeatable quality. | Good to Fair. Seal depends on gasket quality and consistent clamping pressure. Prone to relaxation over time. |

| On-Site Efficiency | Moderate. Requires skilled technicians and is weather-dependent. Prefab boots improve speed. | High. Fast, automated process, and less affected by weather. Ideal for repetitive connections. | High. Relatively simple to install with standard tools and does not require specialized welding labor. |

| Cost & Maintenance | Higher initial labor cost but zero long-term maintenance. Most reliable lifecycle cost. | Higher material cost for fittings but can reduce labor. Zero long-term maintenance. | Lower initial material and labor cost but requires periodic inspection and bolt re-tightening. Higher potential for future repair costs. |

Recommended Connection Methods for Different Projects

- Landfills (Zero-Leakage): The only recommended method is a welded pipe boot. We suggest a primary extrusion weld to create the boot, with a secondary overlap weld of the boot flange to the liner. This allows for air channel pressure testing to guarantee a perfect seal.

- Sewage Treatment Tanks: Chemical resistance is key. A welded connection using a matching PE grade is essential to prevent degradation from chemical exposure.

- Reservoirs / Fish Ponds: Pressure is lower. Prefabricated pipe boots are a great choice for speed and reliability, but a properly installed mechanical flange can also be a cost-effective and sufficient solution.

- Chemical Tanks: For high-corrosion environments, a direct extrusion welded connection is non-negotiable. The weld must be made with a polymer grade certified to resist the specific chemicals being stored.

Common Mistakes and Key Precautions

According to field data, connection failures are almost always due to installation error. Here are the top mistakes to avoid:

- Poor Surface Preparation: Failure to clean oil, dust, and moisture from the surfaces before welding will result in a weak or non-existent bond.

- Incorrect Welding Parameters: Using a temperature that is too high or too low, or a travel speed that is too fast or too slow, will create a faulty weld. All welding must be done by certified technicians.

- Uneven Flange Compression: For mechanical connections, bolts must be tightened in a star pattern to a specified torque (typically 50–150 N·m). Uneven pressure is the #1 cause of mechanical seal failure, accounting for about 50% of leaks.

- Ignoring Thermal Expansion: A system must accommodate thermal movement (25–40 mm per 100m of pipe). Rigid connections can concentrate stress, leading to a rupture.

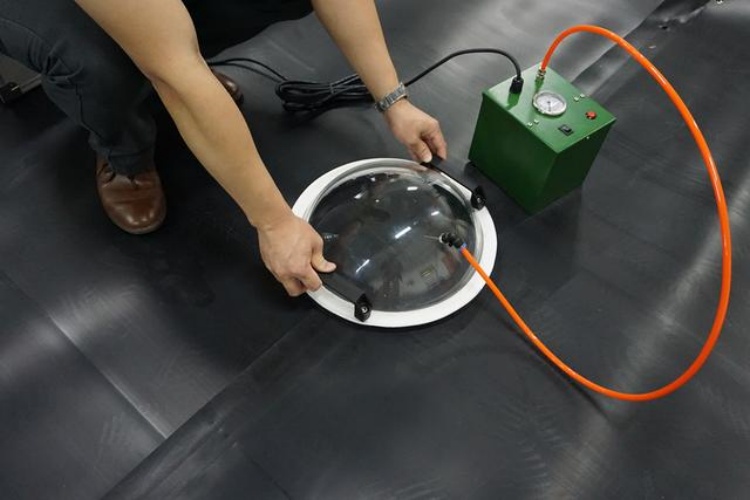

After installation, QA/QC is critical. We use air pressure testing (typically 10–50 kPa) on dual-welded seams to verify 100% seal integrity before backfilling.

How to Choose the Best Connection Method

Choosing the right method comes down to balancing three factors: sealing requirements, site conditions, and budget. For critical applications like landfills or chemical containment, the superior reliability and zero-maintenance nature of a welded connection make it the only professional choice. For lower-risk projects or where connections to non-PE pipes are needed, a mechanical connection offers a practical and cost-effective alternative when installed correctly.