Landfills are not static structures; they are massive, active geotechnical systems that settle and shift for decades. This movement places enormous stress on the liner system, the critical barrier protecting our environment. So, how do we ensure this barrier remains intact? This often leads to a key question from engineers and project owners: do landfill liners really need geogrids?

In this guide, I'll provide a direct answer based on years of supplying materials for these critical projects. We will cover when geogrids are an absolute necessity, when they might be optional, and how to choose the right type to ensure the long-term safety, stability, and profitability of your landfill.

Introduction to Landfill Liner Systems

Before we talk about reinforcement, let's briefly review the system we are trying to protect.

What Is a Landfill Liner System?

A landfill liner is a multi-layered barrier system engineered at the bottom and sides of a landfill. Its primary job is to contain solid waste and prevent contaminated liquid, known as leachate, from escaping into the soil and groundwater. A similar system, the final cover, is placed on top of the landfill after it is full.

Common Components of a Landfill Liner

A modern liner system is a composite structure, typically including:

- A Geomembrane: An impermeable plastic sheet (usually HDPE) that acts as the primary barrier.

- A Geosynthetic Clay Liner (GCL) or Compacted Clay Liner (CCL): A secondary barrier providing redundancy.

- A Drainage Layer: A geocomposite or gravel layer to collect and remove leachate.

- Protective Geotextiles: Fabric layers that protect the geomembrane from puncture.

This system is designed to be a passive barrier. But when a landfill settles unevenly by several meters, passive resistance is not enough. This is where reinforcement becomes critical.

What Are Geogrids and How Do They Work?

To understand their role, you need to know what geogrids fundamentally are.

Definition and Function of Geogrids

A geogrid is a geosynthetic material formed into an open, grid-like configuration. Its primary function is reinforcement. When placed in soil or aggregate, the particles lock into the grid's apertures (openings). When a load is applied, the geogrid's high tensile strength resists the pulling forces, holding the soil mass together and distributing the load over a wider area.

Types of Geogrids Used in Geotechnical Engineering

There are several types, but the most common in civil engineering are:

- Uniaxial Geogrids: High strength in one direction, ideal for applications with a primary stress direction, like retaining walls and steep slopes.

- Biaxial Geogrids: Strength is uniform in two perpendicular directions, ideal for applications like road bases and foundation reinforcement where stresses are multi-directional.

- Triaxial Geogrids: Strength is more evenly distributed in multiple directions, offering enhanced performance for base stabilization.

Geogrids are distinct from other geosynthetics like geotextiles, which primarily function as separators, filters, or drains rather than primary reinforcement elements.

Do Landfill Liners Really Need Geogrids?

This is the core question. The answer is not always yes, but for most modern, large-scale landfills, it is overwhelmingly yes. The decision hinges on risk, geology, and design.

Situations Where Geogrids Are Not Required

You might be able to avoid using geogrids if all of the following conditions are met:

- Foundation: The landfill is built on solid, non-settling bedrock.

- Size & Lifespan: It is a very small, temporary facility with a low waste height.

- المنحدرات: The design incorporates very gentle slopes (e.g., flatter than 3:1).

- Seismic Risk: The site is in a non-seismically active zone.

In my experience, projects that meet all these criteria represent less than 5% of all modern landfill construction. For the other 95%, geogrids are not just an add-on; they are an essential component of risk management.

When Geogrids Become Necessary in Landfill Liners

Geogrids shift from being optional to essential under these common conditions:

- Soft or Compressible Foundations: Most landfills are built on soil, not solid rock. This soil compresses under the immense weight of the waste, leading to uneven or "differential" settlement.

- High Waste Stacks: A 50-meter-high landfill can settle by several meters, with the center settling far more than the edges. This differential settlement places the liner system under immense tension.

- Steep Side Slopes: To maximize valuable airspace, modern landfills are designed with steep slopes (e.g., 2:1 or 1.5:1). Geogrids are required to ensure the stability of these slopes, preventing catastrophic veneer failure.

- Regulatory Requirements: Many environmental regulations require a high factor of safety (e.g., FS > 1.5) against slope failure, which is often unachievable on steep slopes without reinforcement.

Common Failure Risks Without Geogrid Reinforcement

Without geogrids, differential settlement can stretch the liner system past its breaking point. A compacted clay liner can crack when its tensile strain exceeds just 0.5%. These cracks create direct pathways for leachate to escape. The geogrid functions like a "tension membrane" within the soil, absorbing these tensile forces and allowing the liner system to accommodate much larger strains without rupturing. It acts as an insurance policy against cracks and leaks.

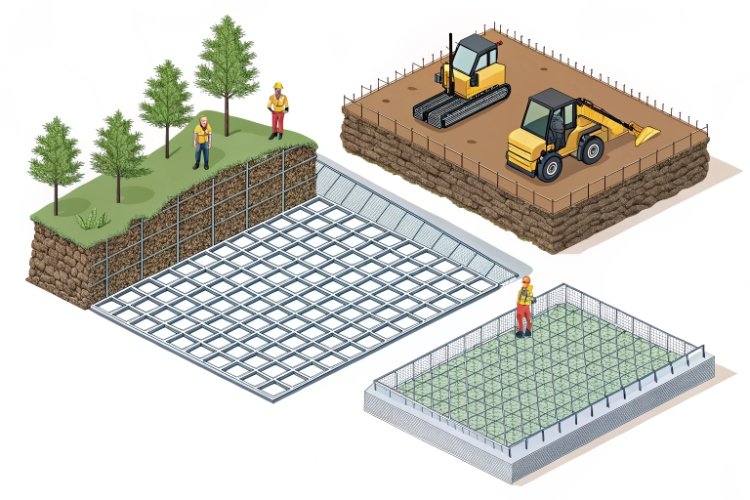

Typical Applications of Geogrids in Landfill Liner Systems

Geogrids are used in several key areas within a landfill to provide structural integrity.

Side Slope Reinforcement

This is the most common and critical application. By layering geogrids horizontally within the slope's soil cover, engineers can design much steeper slopes than would be possible with unreinforced soil. This directly translates to increased waste capacity and revenue for the landfill operator.

Base Liner Stability Improvement

When a landfill is built on a soft foundation, biaxial geogrids are placed within the base liner's soil layers. They create a stiff platform that "bridges" over weaker zones, preventing localized depressions and reducing the tensile stress on the geomembrane and GCL caused by differential settlement.

Reinforcement of Cover Systems

After a landfill is closed, the final cover system is also subject to settlement as the waste below decomposes. Geogrids are used in the cover system for the same reasons as the base liner: to maintain integrity and prevent cracks from forming as the ground shifts.

Interface Shear Strength Enhancement

On steep slopes, there is a risk of the topsoil "veneer" sliding off the smooth surface of the geomembrane. High-strength geogrids placed above the geomembrane provide a textured surface with tensile capacity, interlocking with the soil and dramatically increasing the friction and stability at this critical interface.

Key Specifications to Consider When Choosing Geogrids

Selecting the right geogrid is not about picking the "strongest" one; it's about matching the specifications to the specific engineering need.

Tensile Strength and Load Direction

This is the primary specification, measured in kN/m. It defines how much pulling force the geogrid can withstand before breaking. It's crucial to match the geogrid type (uniaxial, biaxial) to the primary direction of stress in your application.

Junction Strength and Aperture Size

The points where the grid's ribs are connected are called junctions. High junction strength is vital to ensure the grid acts as a cohesive unit. The aperture size (the opening in the grid) must be optimized for the infill material. An opening between 25-50mm typically provides the best interlock with common soil and aggregate fills.

Creep Resistance and Long-Term Performance

Creep is the tendency of a material to slowly deform over time under a constant load. For a landfill designed to last 100+ years, resistance to creep is non-negotiable. High-quality geogrids made from polymers like polyester (PET) or polyvinyl alcohol (PVA) are tested for long-term creep to ensure they maintain their strength for the entire design life of the facility.

Chemical and Biological Resistance

The landfill environment is chemically aggressive and biologically active. The geogrid polymer must be inert and resistant to degradation from leachate, soil chemicals, and microorganisms. Standard PET is stable in most conditions, but in high-temperature or high-pH environments, a more robust polymer like PVA may be required. If the geogrid is part of an exposed slope, UV resistance is also essential.

How to Select the Right Type of Geogrid for Your Project

Here is a simplified framework for making the right selection:

Uniaxial vs. Biaxial Geogrids for Landfills

- Use Uniaxial Geogrids: For reinforcing steep side slopes and retaining walls where the primary stress is horizontal, pulling away from the slope face.

- Use Biaxial (or Triaxial) Geogrids: For reinforcing the landfill base, haul roads, and cover systems where settlement and loads create multi-directional stresses.

Matching Geogrid Type to Slope Angle and Load

The design is always project-specific, but as a general rule:

- Gentle Slopes (e.g., 3:1) & Moderate Settlement: A medium-strength biaxial geogrid (e.g., 50-80 kN/m) may be sufficient.

- Steep Slopes (e.g., 1.8:1) & High Waste Stacks: High-strength uniaxial geogrids (e.g., 300-700 kN/m) layered within the slope are necessary.

- Extremely Steep Slopes (e.g., 1.5:1) or Very High Loads: May require very high-strength geogrids (>900 kN/m) and specialized design.

Design Considerations Based on Regulations and Standards

The final design must be completed by a qualified geotechnical engineer. They will perform calculations to ensure the reinforced system meets or exceeds the required factors of safety for static, seismic, and long-term conditions as mandated by local environmental regulations.

Design and Installation Considerations

A high-quality geogrid is only effective if it's installed correctly.

Placement Location Within the Liner System

Geogrids are not placed in direct contact with geomembranes. They are embedded within compacted soil layers. A typical reinforced base might have 3-4 layers of geogrid interspersed within a 1-meter-thick clay liner. Research shows that for optimal performance, the first geogrid layer should be placed at a specific depth below the surface to effectively mobilize the soil, with subsequent layers spaced to create a true composite material.

Common Installation Mistakes to Avoid

- Poor Subgrade Preparation: The ground beneath the geogrid must be smooth and compacted.

- Inadequate Overlap/Connection: Adjacent geogrid panels must be overlapped and securely fastened according to manufacturer specifications.

- Damage During Installation: Driving heavy equipment directly on an exposed geogrid can damage it. Infill should be placed carefully.

- Insufficient Tensioning: The geogrid must be laid flat and taut to engage properly under load.

Cost vs. Performance: Is Using Geogrids Worth It?

This is a question I get from almost every client. Financially, the decision is surprisingly clear.

Initial Cost vs. Long-Term Risk Reduction

Adding geogrid reinforcement might increase the cost of the geosynthetic system by 10-30%. This may seem significant upfront. However, consider the cost of failure. The a single leak in a liner system can cost millions in remediation—excavating waste, repairing the liner, and paying regulatory fines. The potential liability for groundwater contamination is effectively unlimited.

Compared to these catastrophic risks, the initial investment in geogrids is a very low-cost insurance policy. The financial ROI is realized the moment a failure is prevented.

Impact on Landfill Safety and Service Life

By ensuring stability, geogrids directly contribute to the safety and longevity of the entire facility. Furthermore, by allowing for steeper slopes, they maximize the landfill's capacity, increasing its revenue-generating potential and extending its operational life.

Common Questions About Geogrids in Landfill Liners (FAQ)

Can geogrids replace thicker soil layers?

No, they don't replace soil; they reinforce it. By reinforcing the soil, they allow engineers to achieve the required stability with thinner layers than would be possible with unreinforced soil, saving on material and construction costs.

Do geogrids damage geomembranes?

When installed correctly, no. A protective layer of soil or a nonwoven geotextile is always placed between the geogrid and the geomembrane to prevent any risk of friction or puncture. Damage only occurs as a result of poor design or improper installation.

How long do geogrids last in landfill environments?

High-quality geogrids are designed and manufactured for a service life of over 100 years. This longevity is achieved by selecting the right polymer (e.g., PET, PVA) that can resist chemical degradation and long-term creep for the specific conditions inside the landfill.

Conclusion: Making the Right Decision for Landfill Liner Reinforcement

For the vast majority of modern landfills, the question is not if you need geogrids, but which geogrids you need and where you need them. They are a fundamental engineering tool for managing the immense and long-lasting stresses caused by waste settlement and steep slope designs.

The decision to incorporate geogrids into a landfill liner system is a proactive investment in safety, environmental security, and long-term structural performance. By working with a qualified engineer and choosing the right materials for your specific site conditions, you are not adding a cost—you are building a safer, more resilient, and more profitable facility.