A modern landfill is far more than just a hole in the ground. It's an engineered containment facility designed to protect our environment from waste. The most toxic byproduct, leachate, can contaminate soil and groundwater for decades if it escapes. This is why the landfill lining system is the most critical component, acting as a multi-layered shield.

This guide will walk you through the advanced geosynthetic and natural materials that form a modern landfill liner. We'll explore the role each component plays, from the primary impermeable barrier to the drainage and protection layers, creating an integrated system designed for long-term performance and environmental safety.

Think of this not as a single barrier, but as a sophisticated, redundant system where each material supports the others. Let's break down the components from the inside out.

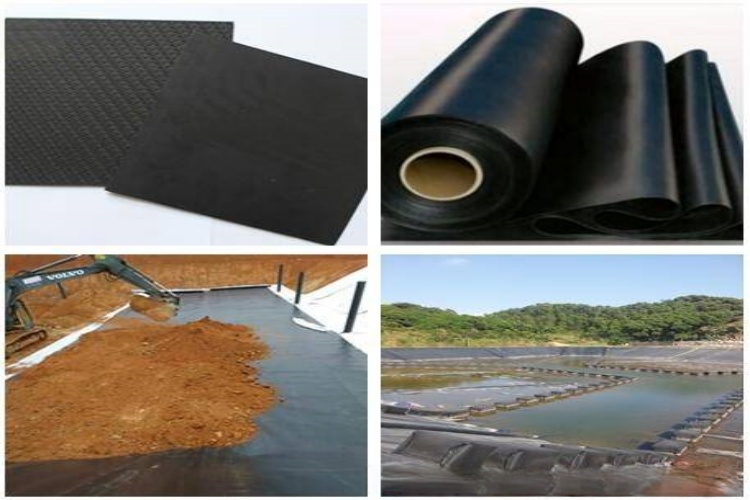

HDPE Geomembrane: The Primary Barrier

The workhorse and primary barrier in almost every modern landfill is the High-Density Polyethylene (HDPE) geomembrane. This robust plastic liner is chosen for its exceptional durability and chemical resistance. It is engineered to withstand the harsh chemical cocktail found in leachate, performing reliably across a wide pH range (typically 1–14).

For landfill applications, HDPE liners are typically specified at thicknesses between 1.5 mm (60 mil) and 3.0 mm (120 mil). This thickness provides excellent impermeability (with hydraulic conductivity as low as 10⁻¹³ m/s) and the physical strength to resist installation stress. With proper UV stabilization, HDPE has a design life of over 50 years. The panels are permanently joined on-site using thermal fusion welding techniques, like hot-wedge welding, to create a continuous, secure barrier.

LLDPE Geomembrane: A Flexible Alternative

While HDPE is the standard, Linear Low-Density Polyethylene (LLDPE) geomembranes also have a place in landfill design. LLDPE's key advantage is its superior flexibility and elongation. This makes it an ideal choice for specific areas within a landfill system.

We typically recommend LLDPE for:

- Areas with potential for differential settlement: Its ability to stretch and conform without failing is crucial where the subgrade may be uneven or settle over time.

- Steeper slopes: Textured LLDPE provides higher interface friction, which is essential for stability when lining the sides of a landfill cell.

- Landfill caps and closures: Its flexibility makes it easier to install over the final contours of the waste mass.

The choice between HDPE and LLDPE involves a trade-off. While LLDPE offers flexibility, HDPE generally has a longer track record for long-term chemical resistance in the most demanding hazardous waste applications. The project engineer will specify the right material based on site-specific conditions.

Geosynthetic Clay Liner (GCL): The Self-Healing Secondary Barrier

Beneath the primary geomembrane, you will often find a Geosynthetic Clay Liner (GCL). This remarkable material acts as a powerful secondary barrier. A GCL is a composite made of a thin layer of sodium bentonite clay sandwiched between two geotextiles.

When the bentonite clay gets wet, it swells to many times its original volume, forming an ultra-low permeability seal. The key advantage of a GCL is its ability to self-heal. If a small puncture occurs, the surrounding hydrated bentonite expands into the void, sealing the leak. This makes it an excellent complementary barrier to the HDPE geomembrane, creating a redundant system that is often required by regulations like the EPA's RCRA Subtitle D.

Compacted Clay Liner (CCL): The Traditional Natural Foundation

Before the advent of GCLs, the traditional secondary barrier was a Compacted Clay Liner (CCL). A CCL is a thick, engineered layer of natural clay (typically 24–60 inches thick) that is compacted to a specific density (95%+ Proctor) and moisture content. When properly constructed, a CCL achieves a low hydraulic conductivity (maximum of 10⁻⁷ cm/s).

While effective, building a CCL is a slow, labor-intensive process that is highly dependent on weather conditions and quality control. Today, a GCL can often replace a much thicker CCL, offering faster installation and more consistent performance. However, in many designs, a CCL is still used as the foundational barrier layer, with a GCL or geomembrane placed directly on top to create a robust composite liner system.

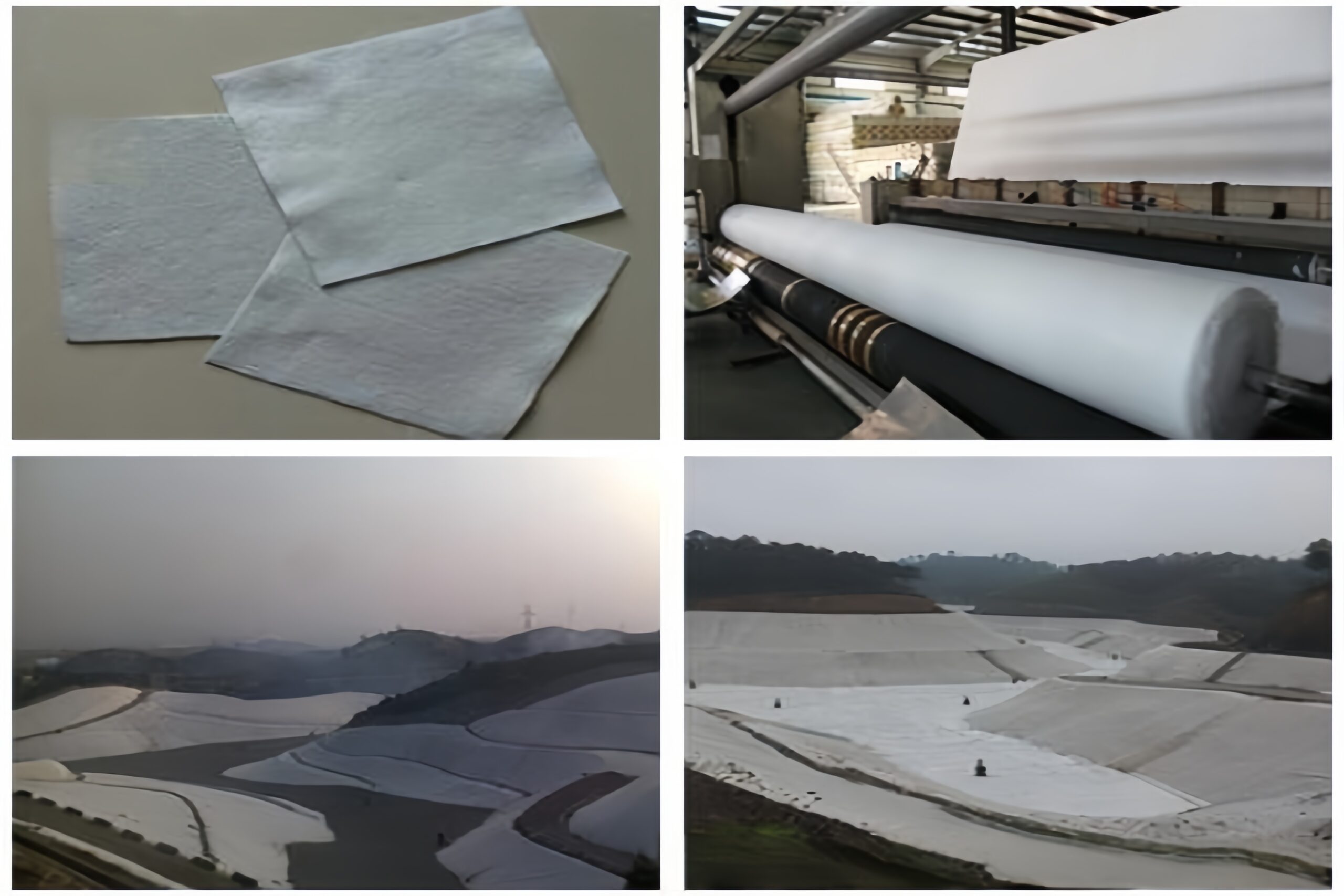

Geotextiles: For Protection, Cushioning, and Filtration

Geotextiles are the unsung heroes of the landfill liner system. These fabric-like materials perform several critical functions that ensure the long-term integrity of the barrier layers.

- Protection and Cushioning: A thick, needle-punched nonwoven geotextile (typically 300–500 g/m²) is placed directly against a geomembrane. It acts as a cushion, protecting the liner from being punctured by sharp objects in the underlying soil or the overlying waste.

- Filtration and Separation: Geotextiles are permeable, allowing water to pass through while holding back soil or waste particles. This prevents drainage layers from clogging and keeps different soil layers separate and stable.

Without this protective layer, the primary geomembrane would be highly vulnerable to damage during construction and operation.

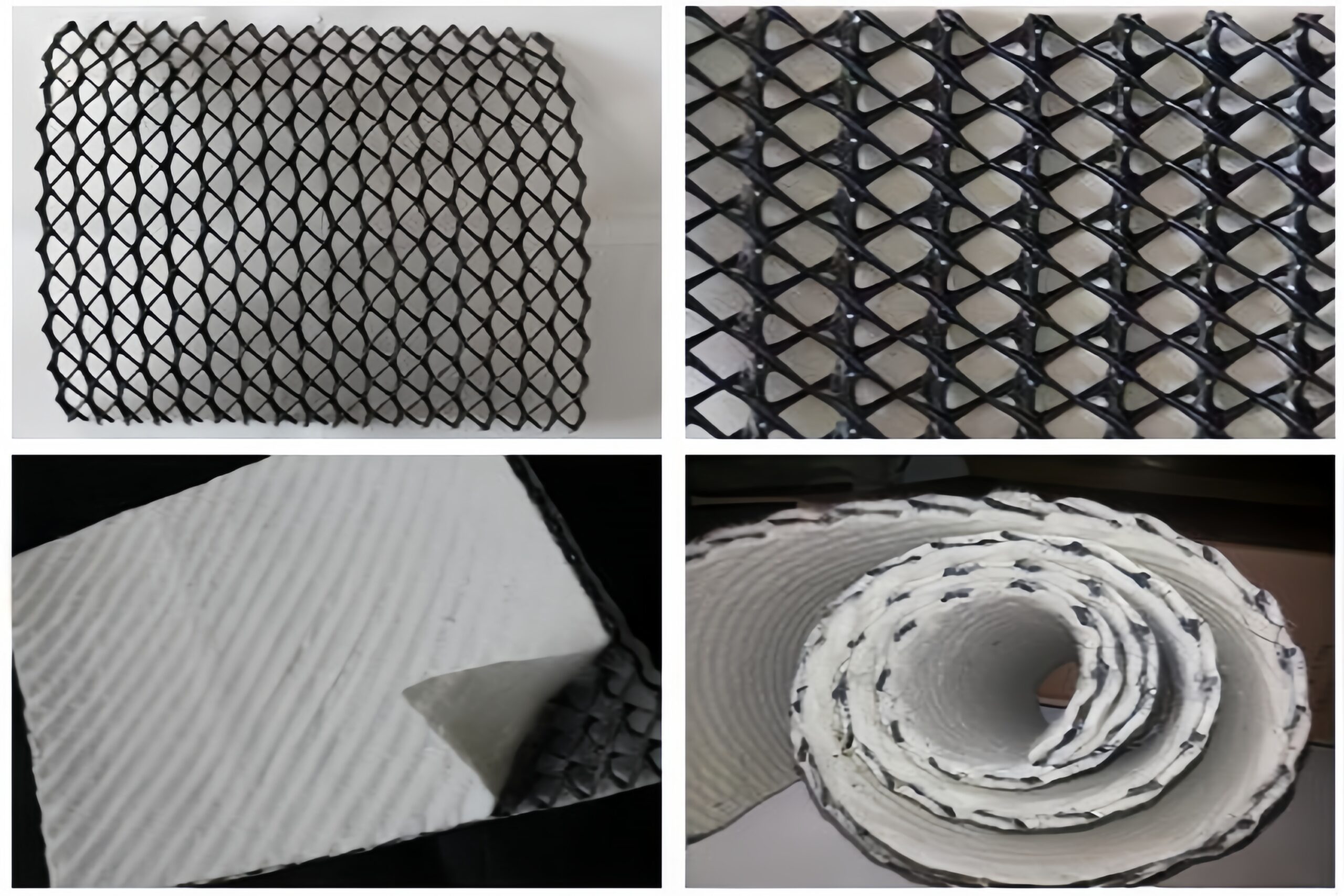

Geonets and Geocomposites: The Leachate Collection Layer

It's not enough to simply contain leachate; you must also collect and remove it. If liquid builds up on top of the liner, the resulting hydrostatic pressure (or "head") can force leachate through any tiny imperfection. This is the job of the drainage layer, which is typically made from geonets or geocomposites.

- Geonets: These are polymer grids with a diamond-shaped structure that creates high in-plane flow capacity for liquids and gases.

- Geocomposites: A geocomposite combines a geonet with one or two layers of heat-laminated geotextile. The geotextile acts as a filter, preventing particles from clogging the geonet's drainage core.

This drainage layer, officially known as the Leachate Collection and Removal System (LCRS), is placed directly on top of the primary geomembrane. It collects leachate and directs it to a series of perforated pipes and sumps, where it can be pumped out for treatment.

Matching Materials to Waste Types

The specific configuration of a liner system depends heavily on the type of waste being contained. Regulations are rightfully stricter for more hazardous materials.

A General Guideline:

- Municipal Solid Waste (MSW): Regulations typically require a composite liner system, such as an HDPE geomembrane over a GCL or a compacted clay liner.

- Hazardous Waste: The standards are even higher, mandating a double-liner system. This usually consists of a primary geomembrane, a leak detection layer (geonet), and a secondary composite liner (another geomembrane over a GCL/CCL).

- Radioactive or Highly Industrial Waste: These niche applications may require specialized materials with documented ultra-long-term performance.

Summary Table of Landfill Components and Costs

This table summarizes the primary materials, their functions, and typical material costs. Note that these are material costs only; total installed costs are significantly higher.

| Component | Primary Function | Typical Material Cost (USD/m²) |

|---|---|---|

| HDPE/LLDPE Geomembrane | Primary impermeable barrier for leachate containment | $2.00 – $5.00 |

| Geosynthetic Clay Liner (GCL) | Secondary self-healing hydraulic barrier | $3.00 – $6.00 |

| Compacted Clay Liner (CCL) | Traditional low-permeability foundation layer | $8.00 – $15.00 |

| Nonwoven Geotextile | Protection, cushioning, and filtration | $1.00 – $4.00 |

| Geonet/Geocomposite | Leachate collection, drainage, and gas venting | $2.00 – $6.00 |

Conclusion

A modern landfill lining system is a testament to geosynthetic engineering. It is not one product but an integrated, multi-component system designed for redundancy and long-term security. From the impermeable HDPE geomembrane to the self-healing GCL and the critical drainage geocomposites, each material plays a vital role. Understanding how these components work together is the first step to ensuring a safe and environmentally responsible containment facility.