In high-stakes mining projects like heap leach pads and tailings storage facilities (TSFs), the geomembrane liner is more than just a barrier against leaks. It's a critical structural component. A failure here isn't just an environmental issue; it's a massive operational risk that can lead to catastrophic slope failure. The stability of the entire system often comes down to one key property: the texture of the liner's surface.

For this reason, in mining applications, liner stability is a design-critical issue rather than a simple material preference. Understanding when to specify a textured geomembrane versus a smooth one is fundamental to ensuring the long-term safety and performance of the facility.

This guide will walk you through the key factors that drive this decision, outlining the specific scenarios where a textured geomembrane is not just recommended, but absolutely required for safe and effective liner system design.

Geomembrane Surface Selection in Mining Liner Systems

The choice between a smooth and textured surface is the first and most important decision related to liner stability.

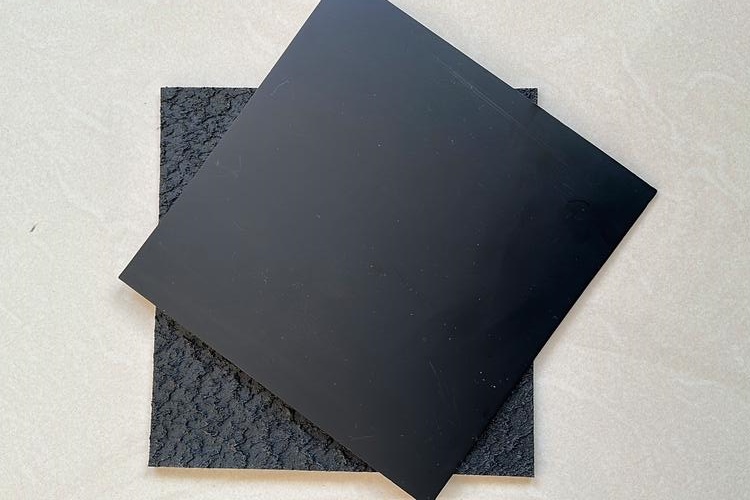

Smooth Geomembranes in Mining

A smooth geomembrane has a uniform, flat surface on both sides. It is the standard, default product for many applications. Within mining, it offers several advantages:

- It generally has a lower material cost.

- The flat surface allows for faster and sometimes easier field seam welding.

Because of these benefits, smooth liners are frequently used in areas where slope stability is not a concern, such as the flat base of a heap leach pad or a solution pond where the primary forces are vertical.

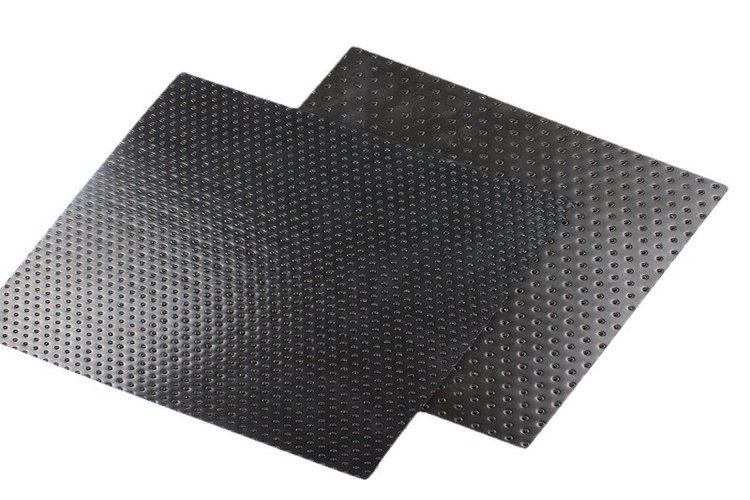

Textured Geomembranes in Mining

A textured geomembrane is specifically engineered with a rough, patterned surface on one or both sides. This texture is created during the manufacturing process and its sole purpose is to increase the frictional resistance between the geomembrane and the adjacent materials (soil, geotextiles, GCLs, or drainage aggregate).

The difference is dramatic. A smooth HDPE geomembrane might have a friction angle of only 10-15° against soil. A textured HDPE geomembrane, under the same conditions, can achieve a friction angle of 30-40°. This 2x to 3x increase in frictional performance is not a minor improvement; it is a game-changing enhancement. Textured geomembranes are primarily used in mining to control liner slippage on slopes and ensure the stability of the entire containment system.

Mining-Specific Factors That Drive the Need for Textured Geomembranes

While other civil engineering projects use textured liners, the conditions in mining are uniquely demanding and often make them a default requirement.

Steep Side Slopes in Heap Leach Pads and TSFs

To maximize ore volume on a limited land footprint, heap leach pads and tailings dams are often designed with the steepest possible side slopes. Slopes of 2H:1V (26.6°) or steeper are common. On these slopes, the force of gravity is constantly trying to pull the overlying ore, soil, and liner materials downhill. A smooth liner simply does not offer enough frictional resistance to counteract this driving force, creating an unacceptable risk of slippage.

Long-Term Hydraulic Loading

In heap leach pads and solution ponds, the liner system is constantly saturated with process solutions. This liquid creates pore pressure at the interface between the liner and the subgrade or overlying materials. This pressure acts like a lubricant, significantly reducing the effective friction between the layers. A textured surface is required to maintain sufficient frictional shear strength even under these fully saturated, low-confinement conditions.

Liner Systems Involving GCLs

Composite liner systems that pair a geomembrane with a Geosynthetic Clay Liner (GCL) are common in heap leach and TSF designs for enhanced environmental protection. However, the interface between a smooth geomembrane and a GCL is notoriously weak, with very low friction angles. Using a smooth geomembrane over a GCL on any significant slope is a well-known recipe for instability and is almost universally avoided in modern mining design. A textured geomembrane is essential to create the necessary interlock with the GCL's surface.

High Required Factors of Safety

Mining structures like TSFs and large heap leach pads are considered high-consequence facilities. Their failure could result in significant loss of life, environmental damage, and financial ruin. Consequently, they are designed with a high Factor of Safety (FS) against failure, typically requiring an FS of 1.5 or greater for static conditions. It is often mathematically impossible to achieve this required Factor of Safety on a slope using the low friction values of a smooth geomembrane. Only the enhanced friction of a textured surface can meet the design requirements.

Mining Scenarios Where Textured Geomembrane Is Typically Required

Based on the factors above, there are several clear-cut applications where a textured geomembrane is the industry standard.

Heap Leach Pad Side Slopes

This is the most common application for textured geomembranes in mining. For any heap leach pad with side slopes, especially those with high ore stacks and long-term operational lives, a textured liner is almost always specified. A double-sided textured geomembrane is often preferred to provide high friction against both the subgrade below and the protective geotextile or drainage material above.

Tailings Storage Facilities (TSFs)

As permanent structures designed to contain potentially toxic materials for perpetuity, TSFs are engineered with extreme conservatism. The liner systems on the slopes of the dam and the basin are designed for long-term stability under seismic and hydraulic loads. Double-sided textured geomembranes are frequently used to ensure maximum frictional resistance at all interfaces within the liner system.

Steep Mining Ponds and Solution Ponds

Process ponds, such as Pregnant Leach Solution (PLS) ponds or raffinate ponds, are often very deep to maximize storage volume. If the side slopes of these ponds are steeper than about 4H:1V, a textured geomembrane is specified to prevent the liner and any overlying protective soil cover from slumping to the bottom of the pond.

Liner Systems with Cover Soil on Slopes

When a geomembrane on a slope needs to be protected with a soil cover, the weight of that soil creates a significant downslope driving force. A textured geomembrane is required to provide the friction needed to hold the cover soil in place and prevent it from eroding or sliding off the liner.

Mining Scenarios Where Smooth Geomembrane Is Often Acceptable

While textured liners are critical for slopes, specifying them everywhere would be inefficient and unnecessarily expensive. There are specific, low-risk zones in mining projects where a smooth geomembrane is not only acceptable but is the more logical and cost-effective choice.

Flat Base Liners of Heap Leach Pads and TSFs

On the floor of a heap leach pad or TSF where the slope is very gentle (typically < 5%), the primary forces on the liner are vertical (downward pressure from the ore or tailings). There are minimal shear forces trying to cause slippage. In these areas, the high friction of a textured liner is not needed, and a smooth geomembrane provides perfectly adequate containment at a lower cost.

Mining Ponds with Gentle Slopes

For large, shallow ponds or containment areas with very gentle side slopes (e.g., flatter than 6H:1V), stability calculations may show that a smooth geomembrane can still achieve the required Factor of Safety. In these cases, a smooth liner can be a safe and appropriate choice.

Dry or Low-Hydraulic-Load Areas

In locations where the liner interface is not expected to be permanently saturated, the reduction in friction due to pore pressure is not a concern. If the slope is moderate and the interface will remain dry, a smooth liner might be sufficient, pending a formal stability analysis.

In mining projects, smooth geomembranes are often intentionally used in these well-defined low-risk zones to optimize the overall liner system cost without compromising safety.

Interface Shear Testing in Mining Liner Design

The decision to use a smooth or textured geomembrane is not a guess. It is a calculated engineering decision based on laboratory testing. Because the conditions in mining are so critical, standard "book values" for friction are rarely accepted.

Instead, project-specific interface shear testing is performed using a large-scale direct shear device. This test measures the actual friction angle between the exact geomembrane, geotextile, GCL, and soil materials that will be used on site, under the specific loads expected in the field. The results of this test provide the data needed for engineers to perform a slope stability analysis and definitively determine if a smooth liner is acceptable or if a textured liner is required to meet the project's Factor of Safety.

Practical Mining Design Approach: Zone-Based Liner Selection

The most common and effective approach in modern mining liner design is to divide the project into different zones based on risk and geometry. This allows for the most efficient use of materials while ensuring safety is never compromised.

A typical heap leach pad design will use this zone-based approach:

- Flat Zones (Pad Base): A smooth geomembrane is used to provide cost-effective containment where shear forces are negligible.

- Side Slopes: A single or double-sided textured geomembrane is used to provide the necessary frictional resistance to ensure the stability of the ore stack.

- Critical Slopes or GCL Interfaces: A double-sided textured geomembrane is specified to provide the maximum possible friction at both the upper and lower interfaces.

This zone-based approach is widely used in mining to balance project safety and cost, placing the high-performance material exactly where it is needed most.

Conclusão

Textured geomembranes are not always required for every square meter of a mining project, but they are an essential and non-negotiable component for ensuring stability in critical areas. Their use is mandatory on the steep, liquid-loaded slopes of heap leach pads and TSFs where failure is not an option.

Conversely, smooth geomembranes have very clear and appropriate uses in the flat, low-risk zones of these same projects. A well-engineered design uses both types of liner intelligently, leveraging the strengths of each to create a system that is both safe and economically efficient. The key is to let the site-specific conditions and a proper engineering analysis dictate the selection.