Need a waterproof liner for a project with complex shapes or uneven ground? Using a rigid material can cause installation headaches, stress points, and potential leaks, jeopardizing your containment goals.

PVC geomembrane is a highly flexible, thermoplastic liner made from polyvinyl chloride resin, plasticizers, and stabilizers. It is used in engineering projects by welding it into a continuous, waterproof barrier for applications like canals and ponds where it must conform perfectly to irregular surfaces.

This unique flexibility sets PVC apart from other geomembranes and makes it the ideal choice for a specific range of civil and environmental applications. To select the right liner for your project, it's essential to understand what makes PVC different, how it works, and where it performs best.

What makes PVC geomembrane different from other liner materials?

Confused by the different liner options like HDPE and PVC? Choosing the wrong one can lead to difficult installation or premature failure if the material’s properties don't match your site's demands.

The main difference is PVC's exceptional flexibility, which comes from added plasticizers. This allows it to drape and conform perfectly to uneven subgrades and detailed structures where more rigid liners like HDPE would require more earthwork or risk stress cracking.

This flexibility is a significant engineering advantage, but it also comes with a trade-off. The plasticizers that make PVC so pliable can degrade over time with heavy UV exposure, which is why it's often used in buried or covered applications. For an importer or engineer, matching this property profile to the project requirements is critical for making a cost-effective and reliable decision.

PVC vs. HDPE: A Quick Comparison

| Recurso | PVC (Polyvinyl Chloride) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Flexibility | Very High | Rigid |

| Subgrade Conformity | Excelente | Fair to Good |

| Primary Seaming | Thermal/Solvent Welding | Thermal Fusion Welding |

| UV Resistance (Std) | Fair to Good (Best when covered) | Excelente |

| Melhor para | Canals, tunnels, decorative ponds, caps. | Landfills, large reservoirs, mining. |

How does PVC geomembrane provide effective waterproofing and flexibility?

It can seem counterintuitive that a liner so flexible can provide robust, long-term containment. How does it maintain its integrity and prevent leaks when stretched and folded over complex shapes?

Waterproofing is achieved by using large, factory-fabricated panels that are welded on-site with thermal or solvent methods to create a single, leak-proof sheet. Its flexibility comes from plasticizer molecules integrated into the vinyl resin, allowing the material to elongate and bend without compromising its structure.

One of the biggest advantages of working with PVC is the ability to prefabricate massive panels—sometimes over 3,000 square meters (40,000 sq ft)—in a factory-controlled environment. This drastically reduces the amount of tricky, time-consuming welding that needs to be done on the job site. Fewer field seams mean fewer opportunities for installation error and a higher-quality finished product. This combination of material pliability and installation efficiency makes PVC a powerful solution for complex waterproofing challenges.

Where is PVC geomembrane most commonly applied in civil and environmental projects?

To get the most out of PVC's unique properties, you have to use it in the right application. Using it in the wrong environment, such as one with high UV exposure or incompatible chemicals, can reduce its service life.

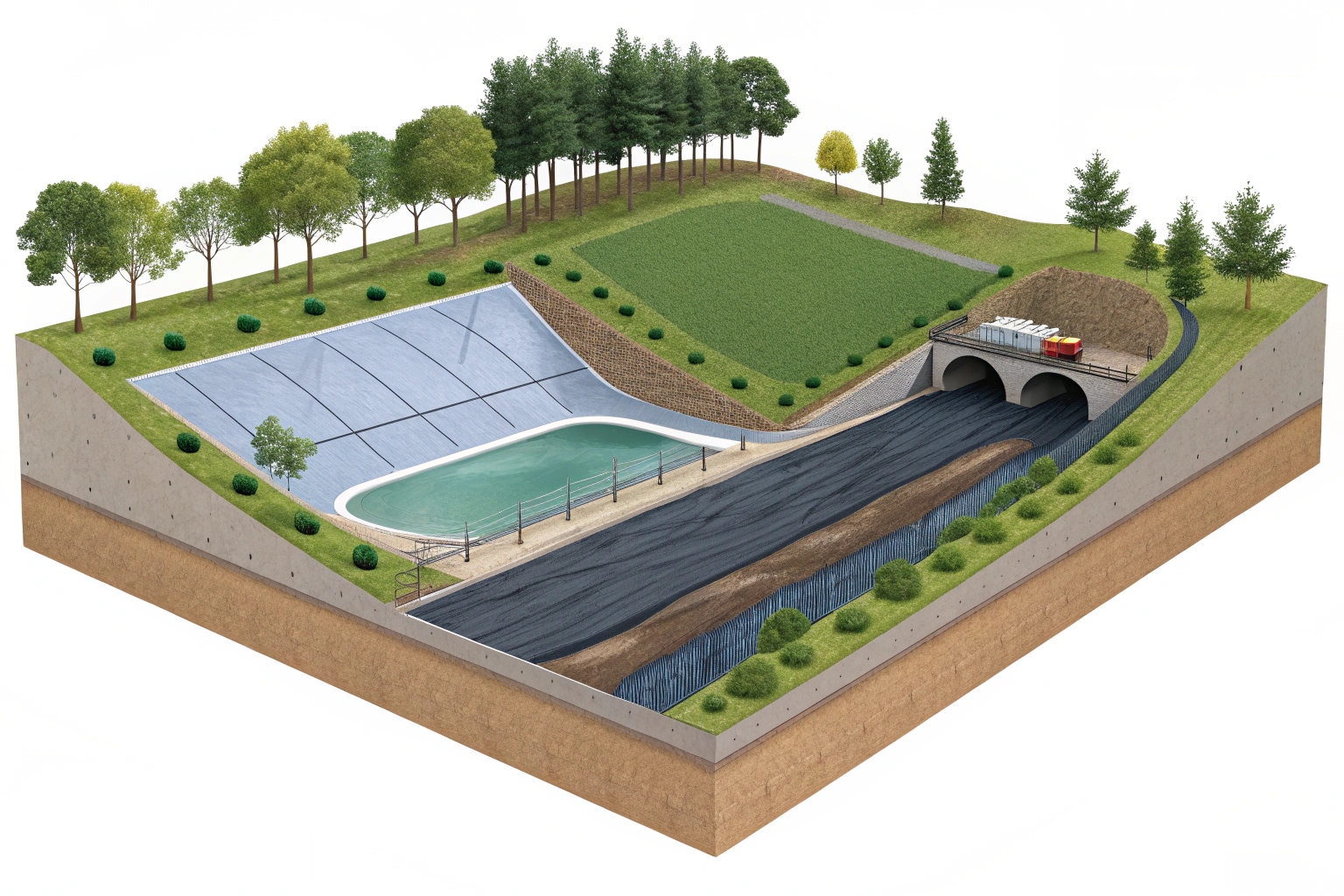

PVC geomembrane is most commonly applied where high flexibility and conformability are critical. This includes irrigation canals, landfill caps, tunnels, decorative ponds, and secondary containment for tanks, where the liner must flawlessly adapt to curves, corners, and potential ground settlement.

PVC excels in these specific scenarios because its pliability reduces installation stress and ensures intimate contact with the subgrade, minimizing voids. For any project with complex geometry, PVC is often the most practical and cost-effective choice.

Key Applications for PVC Geomembrane:

- Irrigation Canals: Easily conforms to the winding paths and uneven banks of canals to prevent water loss.

- Landfill Caps: Drapes effectively over contoured waste mounds to provide a secure, waterproof cover.

- Decorative Ponds: Perfect for custom-shaped architectural water features and garden ponds.

- Tunnels and Foundations: Provides a reliable waterproofing layer against external water pressure in underground structures.

- Tank Liners: Can be fabricated to fit inside existing concrete or steel tanks for corrosion protection or secondary containment.

How can I choose high-quality PVC geomembrane for long-term performance?

Sourcing PVC liner but worried about getting a low-quality product? A bad batch can become brittle and fail quickly, turning what seemed like a cost-saving into a budget-breaking replacement project.

To choose a high-quality PVC geomembrane, verify its compliance with industry standards like ASTM. Analyze the technical data sheet for thickness, tensile strength, and puncture resistance. Prioritize suppliers who offer large, factory-prefabricated panels and provide full quality assurance documentation.

The quality of a PVC liner is determined by its formulation. A premium product uses high-grade plasticizers and stabilizers to ensure long-term flexibility and durability. When evaluating suppliers, ask about their manufacturing process and quality control. Reputable manufacturers will be transparent about their material specs and certifications. For added security, consider a liner with a colored "signal layer," a thin top layer that reveals damage through a contrasting color, making post-installation inspections simple and effective.

Conclusão

PVC geomembrane offers unparalleled flexibility, making it an ideal waterproofing solution for projects with complex shapes and uneven surfaces. Choosing a quality-certified product ensures reliable, long-term performance and containment.