Worried an exposed geomembrane will crack and fail under the sun? Project failure and liner replacement are costly risks. Choosing a liner with the right UV stabilizers is key.

Yes, geomembranes can be used exposed, but only if they are specifically formulated with UV stabilizers, such as a high-quality carbon black. Without these additives, direct sunlight will cause rapid degradation, embrittlement, and failure. Always verify the material's UV resistance before specifying for an exposed application.

While selecting a UV-resistant material is the first step, it's not the only factor determining a successful installation. Polymer type, site conditions, and maintenance practices all play a critical role in how long your exposed liner will actually last. Let's dive deeper into what happens when a geomembrane is left uncovered.

What happens when geomembrane is exposed to sunlight and weather conditions?

Leaving a liner exposed without knowing the risks seems straightforward, but this can lead to premature failure. The sun's energy can break down the material, causing leaks and environmental hazards.

When exposed to sunlight, the polymer chains within the geomembrane absorb UV radiation, leading to a process called photodegradation. This breaks down the material, causing it to become brittle, lose tensile strength and flexibility, and eventually crack, compromising its containment function.

The primary culprit is ultraviolet (UV) radiation, which initiates a chemical chain reaction. This process is accelerated by heat and oxygen. The key effects on the geomembrane include:

1. Polymer Chain Scission

UV energy breaks the long molecular chains that give the geomembrane its strength and flexibility. Shorter chains result in a weaker, more brittle material that is susceptible to cracking under stress, such as from temperature changes or physical impact.

2. Depletion of Additives

Protective additives like antioxidants are consumed over time as they work to combat degradation. Once these are depleted, the polymer itself begins to degrade at a much faster rate, marking the end of the material's functional service life. The visible signs of this degradation are often surface cracking, discoloration (chalking), and increased stiffness.

How do material types like HDPE, LLDPE, and PVC differ in UV resistance?

Assuming all geomembranes offer the same sun protection can lead to a costly mismatch. Specifying a material with poor UV resistance for an exposed project guarantees premature failure and replacement costs.

HDPE, when properly formulated with 2-3% high-quality carbon black, offers excellent, long-term UV resistance. LLDPE requires similar stabilization. PVC's UV resistance is highly dependent on its specific additive package and it can become stiff over time as plasticizers migrate.

The polymer itself is only part of the story; the additive package is what truly determines UV performance. Here’s a practical comparison for buyers:

-

HDPE (High-Density Polyethylene): Considered the industry standard for exposed applications. The carbon black not only provides pigmentation but acts as a powerful UV absorber, effectively shielding the polymer. A well-made HDPE geomembrane can have an exposed service life of over 20-30 years.

-

LLDPE (Linear Low-Density Polyethylene): Like HDPE, its UV resistance comes from a carbon black additive package. While more flexible than HDPE, its long-term exposed performance is similarly dependent on the quality and dispersion of these stabilizers.

-

PVC (Polyvinyl Chloride): PVC is not inherently UV resistant and relies entirely on a complex package of UV absorbers and heat stabilizers. While high-quality formulations can perform well for years, lower-cost PVC may degrade quickly. A common failure mode is plasticizer loss, leading to significant stiffening and cracking.

| Material | Primary UV Stabilizer | Typical Exposed Performance |

|---|---|---|

| HDPE | Carbon Black (~2.5%) | Excellent (decades) |

| Llde | Carbon Black (~2.5%) | Very Good |

| PVC | UV Absorbers / HALS | Fair to Good (formulation-dependent) |

What engineering factors affect the durability of exposed geomembrane installations?

Thinking material selection is the only factor for durability is a mistake. Site-specific conditions can drastically shorten the life of even the best UV-resistant geomembrane if not properly accounted for.

Beyond the material itself, durability is affected by site location (latitude and altitude), climate (temperature cycles, humidity), and installation details like slope angle. Thicker membranes and proper anchoring to manage thermal expansion and contraction are critical engineering considerations.

Several external factors can accelerate or mitigate the aging process. As an importer or contractor, you must consider these during the design and specification phase:

Environmental Stresses

- Solar Irradiance: A project at high altitude or near the equator will receive significantly more intense UV radiation, accelerating material aging.

- Thermal Cycles: Daily and seasonal temperature swings cause the geomembrane to expand and contract. This mechanical stress, especially around seams and anchor points, can lead to fatigue failure if not properly managed in the design.

- Wind: High winds can cause liner uplift ("whales") or fluttering, which creates repeated stress that can weaken the material over time, particularly at the seams.

Installation and Design Factors

- Thickness: A thicker geomembrane (e.g., 1.5mm vs 1.0mm) provides more material to absorb UV energy and resist physical damage, effectively extending its service life.

- Slope Angle & Orientation: A slope facing the equator will receive more direct sunlight than one facing away from it, impacting its aging rate.

How can I extend the service life of geomembrane used in exposed applications?

Installing an exposed geomembrane and then forgetting about it is a recipe for failure. Proactive measures are needed to protect your investment and ensure long-term performance, avoiding costly future repairs.

The most effective way to extend the service life is to cover the geomembrane with a protective layer of soil, concrete, or a sacrificial geotextile. For truly exposed areas, select thicker, high-quality HDPE and conduct regular inspections for early signs of degradation.

While using a high-quality UV-resistant geomembrane is essential, you can take further steps to maximize its lifespan and protect your project:

The Best Method: Covering

The ultimate protection from UV radiation and extreme temperatures is a cover material. This is the single most effective strategy. Options include:

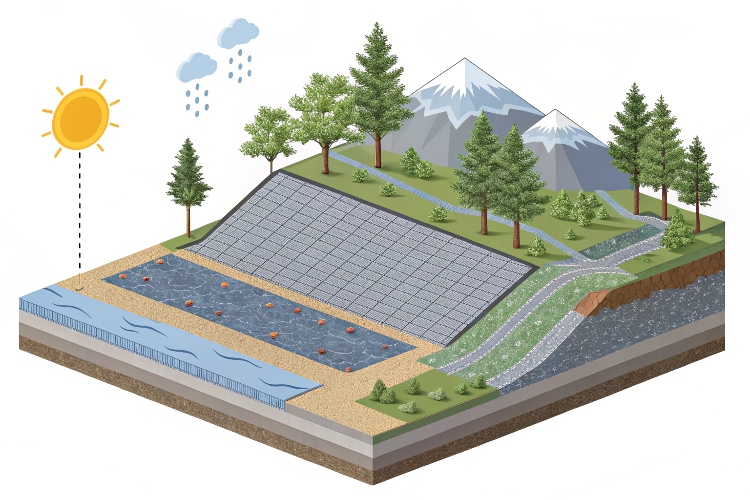

- Soil or Aggregate: A layer of at least 30 cm (12 inches) of soil or rounded aggregate completely blocks UV rays and moderates temperature swings.

- Concrete or Shotcrete: Provides robust, permanent protection for applications like canal lining.

- Geotêxtil Protetor: A heavy, UV-stabilized nonwoven geotextile can be laid over the geomembrane as a sacrificial layer, absorbing the brunt of the environmental stress.

Best Practices for Exposed Liners

If covering is not an option:

- Specify Thickness: Opt for a thicker membrane (e.g., 1.5 mm / 60 mil or greater) for better durability.

- Ensure Quick Installation: Do not leave geomembrane rolls or un-seamed panels exposed to the sun for prolonged periods before final installation.

- Regular Inspections: Periodically inspect the liner for any signs of surface cracking, chalking, or brittleness, especially in high-stress areas.

Conclusão

Yes, geomembranes can be used exposed if properly formulated with UV stabilizers like carbon black. For maximum service life, however, covering the liner is always the best engineering practice.