You're at a critical point in your project: connecting a flexible geomembrane to a rigid concrete structure. A failed connection at this interface is a primary source of leaks and project failure.

The most common methods are mechanical batten strips for existing concrete and embedded anchor strips for new concrete. For new construction, embedding and then welding the geomembrane to the strip is by far the most reliable, watertight, and durable method, creating a truly monolithic seal.

From my experience shipping materials for countless containment projects, this connection detail is where a project's long-term success is often decided. Choosing the right method isn't just a technical preference; it's a critical decision that impacts cost, installation speed, and, most importantly, the watertight integrity of your entire system. Let's break down the options so you can choose the right one for your specific situation.

What factors influence the selection of a bonding method between geomembranes and concrete?

You have several bonding methods to choose from, but picking one at random is a recipe for disaster. This choice can lock you into a high-maintenance solution or even one doomed to fail.

The single most important factor is whether the concrete is new or existing. For new structures, you have superior options. Other key factors include the required level of watertightness, the type of load it will endure, and the project's design life.

When I help clients plan a project, we always start with the concrete itself. If you are pouring new concrete, you can use an embedded anchor strip, which is the gold standard. If you are retrofitting an existing concrete structure, you are limited to mechanical or adhesive methods. After that, we assess the performance requirements. Is this a critical containment system where zero leakage is acceptable, like in a chemical pond or landfill sump? Or is it a canal lining where minor seepage is less critical? The load, whether it’s constant water pressure (hydrostatic) or pulling forces (shear), also determines which method has the necessary strength and durability for the job.

Which mechanical fastening methods—such as batten strips or anchor bolts—are commonly used for geomembrane-to-concrete bonding?

You need to attach a geomembrane to an existing concrete wall or foundation. Drilling holes seems like the only option, but you're rightly concerned about creating potential leak paths.

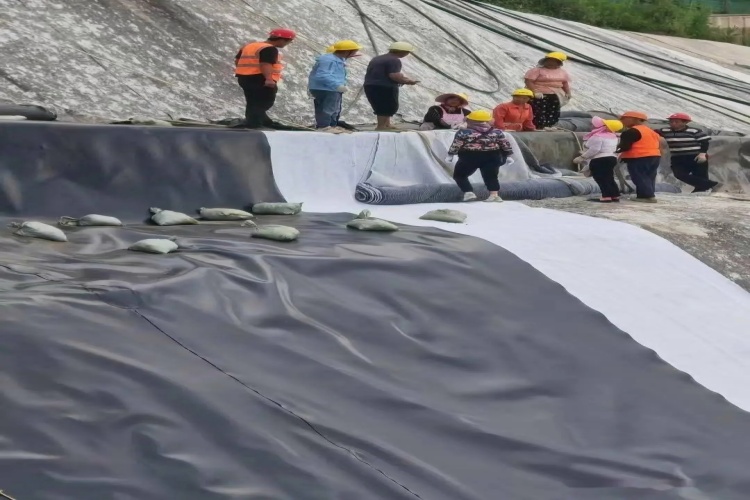

The most common and traditional mechanical method is the batten strip system. This technique uses a metal or plastic bar (the batten), a compressible rubber gasket, and anchor bolts to mechanically clamp the geomembrane firmly against the concrete surface.

The batten strip is the workhorse for retrofitting projects. The installation involves pressing the geomembrane against the clean concrete surface, placing a continuous strip of neoprene or butyl rubber gasket over it, and then bolting down a stainless steel or aluminum batten strip on top. The bolts, typically spaced every 200-300 mm (8-12 inches), create the compressive force that forms the seal. While effective, this system's main weakness is that it creates hundreds of perforations in the liner. Over time, bolts can loosen due to vibration or thermal cycles, and the gasket material can age and lose its elasticity. This means a batten strip system requires regular inspection and maintenance to ensure it remains watertight throughout its service life.

How do adhesive or sealant-based methods perform when bonding geomembranes to concrete surfaces?

You want to avoid drilling holes altogether and are considering adhesives. It sounds like a simple, clean solution, but you worry if it's strong and durable enough for a serious containment application.

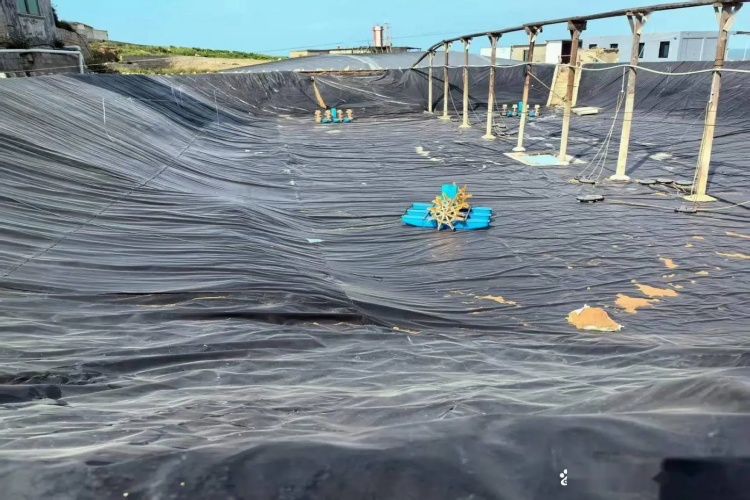

While specialized adhesives exist, the superior method for new concrete is the embedded anchor strip. This system involves casting a high-density polyethylene (HDPE) strip directly into the concrete, which then allows the geomembrane to be welded to it, creating a fully integrated, seamless bond without any perforations.

Let's be clear: for most high-stress applications, relying solely on adhesives is risky and not recommended. Their long-term performance can be unreliable. However, for new construction, the embedded anchor strip (often called a "polylock" or "T-lock") is a game-changer. Before the concrete is poured, these C-shaped or T-shaped HDPE strips are fixed to the inside of the formwork. When the concrete cures, it flows around the strip's profile, locking it in place permanently. The result is a flat, exposed HDPE surface that is flush with the concrete. Your installation crew can then use standard thermal welding equipment to weld the geomembrane directly to this embedded strip. This creates a continuous, high-strength bond that is as strong as the geomembrane itself. It is faster to install, often cheaper (no stainless-steel hardware needed), and requires zero long-term maintenance.

How can I evaluate long-term durability and watertightness when choosing a geomembrane–concrete bonding method?

You need a connection that will last for decades, not just a few years. Choosing a method with hidden long-term weaknesses can lead to costly repairs and operational downtime.

To evaluate durability, compare the fundamental failure points. A welded embedded strip has the highest durability because the bond is molecular and continuous. A batten strip's durability is limited by the lifespan of its mechanical components—bolts that can loosen and gaskets that can degrade.

The difference in long-term reliability is stark. An embedded anchor, once welded, becomes a single, unified part of the liner system. There are no bolts to retighten, no gaskets to replace, and no perforations that can enlarge or leak over time. Its watertightness is absolute because the seal is welded. The batten strip relies on continuous pressure to maintain its seal. This mechanical compression can be compromised by something as simple as a temperature change causing the components to expand and contract at different rates. For any project where long-term, maintenance-free performance is the goal, the choice is clear.

Here’s a quick summary I use to help clients decide:

| Method | Watertightness | Long-Term Reliability | Maintenance | Best Use Case |

|---|---|---|---|---|

| Batten Strip | Bom | Moderado | Required | Existing Concrete |

| Embedded Anchor | Excelente | Excelente | None | New Concrete |

| Adhesive Bonding | Fair | Low to Moderate | Unpredictable | Low-stress, non-critical |

Conclusão

For new concrete, always choose an embedded anchor strip for a superior, maintenance-free, and completely watertight bond. For existing structures, the batten strip is a reliable method, but budget for regular inspections.