Managing landfill leachate is a non-negotiable part of environmental protection. This toxic liquid cocktail, if allowed to accumulate, can exert tremendous pressure on a liner system, threatening to breach it and contaminate groundwater. For years, the default solution was a thick gravel layer, but this method is costly, space-consuming, and environmentally taxing.

This in-depth guide details how modern geosynthetics—specifically drainage nets and composites—provide a superior engineering solution for leachate management. We will explore their structure, compare their efficiency, and show how they integrate into high-performance liner systems to build safer, more stable, and higher-capacity landfills that meet and exceed modern regulatory standards.

To appreciate the impact of these materials, we must first understand the fundamental role they play in controlling the single greatest risk in any landfill: hydraulic head.

Understanding the Role of Drainage Nets and Composites in Leachate Control

Leachate pooling on a geomembrane creates "hydraulic head," a column of liquid that exerts downward pressure. Per critical regulations like the U.S. Resource Conservation and Recovery Act (RCRA), this head must be kept below 300 mm. The reason is simple: high pressure can force leachate through even microscopic imperfections in a liner, leading to significant leakage.

The sole purpose of a drainage layer is to remove leachate faster than it accumulates, keeping this hydraulic head low. While a 300-500 mm thick gravel layer can do this, it occupies valuable airspace that could otherwise be used for waste, thereby reducing the landfill's capacity and revenue. This is where geosynthetics offer a revolutionary advantage.

Structure and Function of Geonets in Landfill Drainage Systems

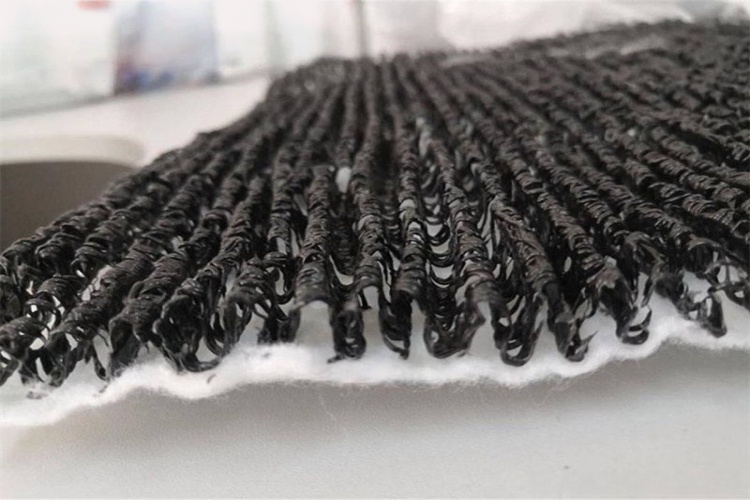

A geonet is the foundational component of a geosynthetic drainage system. It's a three-dimensional grid structure, typically manufactured from high-density polyethylene (HDPE), that functions as a highly efficient conduit for liquid and gas. Its core purpose is to create a predictable and high-volume void space.

When placed within a liner system, a geonet creates an uninterrupted, in-plane pathway. This allows leachate to flow freely and quickly toward collection pipes and sumps. A key advantage over gravel is its performance under load. Geonets are engineered to maintain a high flow capacity (transmissivity) even under the immense compressive stress found at the bottom of a deep landfill, ensuring leachate continues to flow effectively for decades.

How Geocomposite Drainage Layers Enhance Flow Capacity and Filtration

A drainage geocomposite improves upon the geonet by bonding a nonwoven geotextile to one or both sides of the geonet core. This creates a multi-functional material that provides both drainage and filtration in a single product.

- The Geonet Core: This continues to serve as the high-flow "drainage highway."

- The Geotextile Filter: This acts as a separator and filter. It allows leachate to easily pass into the geonet core but physically blocks the fine particles of soil, sludge, and waste.

This filtration function is critical for long-term performance. It prevents the drainage channels of the geonet from becoming clogged with sediment (mechanical clogging) or biological growth (bioclogging), ensuring the system remains effective throughout the landfill's entire operational life.

Comparison: Geonets vs. Geocomposites in Leachate Collection Efficiency

While related, geonets and geocomposites serve slightly different roles. A standalone geonet is excellent for applications where clogging is not a primary concern, such as in a leak detection layer between two geomembranes where the liquid is expected to be clean.

However, for a primary leachate collection system in direct contact with waste, a geocomposite is essential. The geotextile filter is non-negotiable for preventing clogging. A drainage system that clogs is a system that fails, leading to increased hydraulic head and unacceptable risk. Therefore, while a geonet provides the flow, a geocomposite provides the long-term, reliable performance required for primary containment.

Impact on Landfill Stability: Reducing Pore Pressure and Preventing Clogging

The benefits of a geocomposite extend beyond just liner protection. By efficiently removing liquid from the waste mass, it directly contributes to the landfill's overall geotechnical stability. It does this by reducing pore water pressure—the pressure of water filling the spaces between waste particles. High pore pressure reduces the frictional strength of the waste mass, increasing the risk of slope instability and failures. An effective drainage composite mitigates this risk.

Furthermore, the nonwoven geotextile component is engineered to prevent system failure from clogging. These textiles can block over 99% of fine suspended solids while maintaining high permeability, ensuring water gets in but sediment stays out. Advanced research has even led to geotextiles coated with materials like graphene oxide (GO), which can inhibit bacterial growth and reduce the risk of bioclogging by up to 80%.

Integration with Geomembranes and GCLs in Composite Liner Systems

Modern landfills rely on a multi-barrier "defense in depth" strategy, and drainage geocomposites are a key player. A state-of-the-art double-liner system is typically composed of:

- Primary Leachate Collection: A drainage geocomposite placed directly under the waste.

- Primary Liner: A high-quality HDPE geomembrane.

- Leak Detection System (LDCRS): A second drainage geonet or geocomposite.

- Secondary Liner: A second HDPE geomembrane and/or a Geosynthetic Clay Liner (GCL).

In this configuration, the geocomposite serves two roles. The top layer collects the primary leachate. The middle layer acts as a rapid leak detection sensor. If any liquid breaches the primary geomembrane, it is immediately intercepted by the LDCRS and channeled to a monitoring sump, alerting operators to a problem long before contaminants can reach the environment. Such systems achieve a leachate collection efficiency of over 98%.

Performance Considerations: Slope, Load, Clogging Resistance, and Chemical Exposure

Selecting the right drainage product requires a careful review of its technical specifications to match site-specific conditions.

| Performance Indicator | Recommended Value | Significance |

|---|---|---|

| Hydraulic Transmissivity | ≥0.3 × 10⁻³ m²/s | The core measure of in-plane flow capacity under load. Ensures the system can handle expected leachate volumes. |

| Compressive Strength | >3000 kPa | The ability to resist crushing under the weight of deep waste, thereby preserving the flow channels. |

| Long-Term Flow Retention | ≥70% (over 20 years) | Guarantees sustained performance after accounting for material creep and potential clogging factors. |

| Geotextile Permeability | ≥1 × 10⁻³ m/s | Ensures the filter layer allows water to pass through freely without impeding flow into the core. |

| Bond Strength | ≥0.3 kN/m | The peel strength between the geotextile and geonet, ensuring the layers do not separate during installation or service. |

It is also crucial to ensure the HDPE resin used is 100% virgin material with appropriate antioxidants and UV stabilizers to resist chemical degradation from aggressive leachate over a 50+ year design life.

Case-Based Recommendations for Selecting the Right Drainage Product

The versatility of drainage composites allows them to be used in all major areas of a landfill project.

- Bottom (Basal) System: This is the most critical application. A robust geocomposite is laid over the primary liner, with a design slope of ≥1% to channel leachate toward collection pipes. Its primary role is to keep the leachate head below the 300 mm regulatory limit.

- Side Slopes: On steep slopes, a geocomposite provides drainage to enhance stability, prevents erosion of cover soils, and directs leachate down to the basal collection system. Products with high tensile strength (≥25 kN/m) are often specified here.

- Final Cover (Cap): In the final landfill cap, a drainage composite is placed over the capping geomembrane. Its function here is to intercept and drain rainwater, preventing it from ponding on the cap and infiltrating the waste mass. This significantly reduces the long-term generation of new leachate.

Conclusão

Drainage geocomposites are a transformative technology in waste containment. They replace thick, costly, and inefficient gravel layers with a thin, high-performance, and factory-quality-controlled solution. By providing efficient drainage, robust filtration, and long-term clogging resistance, they directly increase a landfill's capacity, enhance its structural stability, and provide the multi-layered defense necessary to protect our groundwater for generations to come. They are the undisputed standard for modern, engineered landfill design.