You're trying to trim your project budget and that line item for "geotextile fabric" seems like an easy cut. But this small saving now can lead to a massive structural failure later.

Geotextile is necessary when you must separate different soil layers, reinforce weak ground, or manage water flow. It is non-negotiable for roads on soft soil, drainage systems, and retaining walls, where omitting it often leads to premature failure and costly repairs.

ك supplier who ships geotextiles worldwide, I've seen the expensive consequences of skipping this critical material. A contractor tries to save a few thousand dollars, only to spend ten times that amount a year later fixing a rutted parking lot or a clogged drainage system. The question isn't whether you can afford to use geotextile, but whether you can afford the risks of not using it. Let's break down exactly when this fabric goes from being a good idea to an absolute necessity.

What main functions does geotextile provide in engineering applications?

You see a roll of fabric, but what does it actually do? Using a geotextile without understanding its core purpose is like taking medication without knowing its effect—you're just hoping for the best.

A geotextile provides five critical functions: separation, filtration, drainage, reinforcement, and protection. Each function solves a specific problem, from preventing soil mixing to increasing the load-bearing capacity of the ground.

More Than Just a Piece of Fabric

From my experience, the biggest mistake importers make is thinking of geotextile as a single-purpose product. In reality, it's a versatile engineering tool designed to perform specific jobs that are vital for long-term stability. The type you need depends on which function is most important for your project.

-

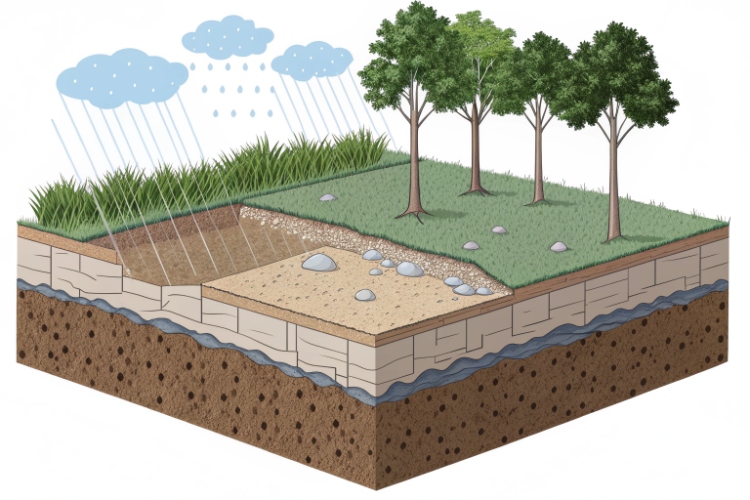

الانفصال

Think of laying a new gravel driveway over muddy ground. Without separation, the gravel will sink into the mud, and the mud will pump up into the gravel. A geotextile acts as a barrier, keeping the two layers distinct and preserving the strength of the gravel layer. -

الترشيح

This is like a coffee filter for your soil. In projects like retaining walls or french drains, a filtration geotextile allows water to pass through freely but stops soil particles from washing away. This prevents drains from clogging and soil from eroding from behind walls. -

الصرف الصحي

Certain thick, nonwoven geotextiles can act as a drain themselves. They collect water and transmit it along the plane of the fabric to an outlet, which is useful in applications like sports fields or behind shotcrete walls. -

تعزيز

Just like rebar strengthens concrete, a high-strength woven geotextile can reinforce soil. By spreading a heavy load (like a truck) over a wider area, it increases the ground's bearing capacity and reduces rutting. -

حماية

In applications like landfills or ponds, a thick nonwoven geotextile acts as a cushion to protect a waterproof geomembrane liner from being punctured by sharp rocks in the soil.

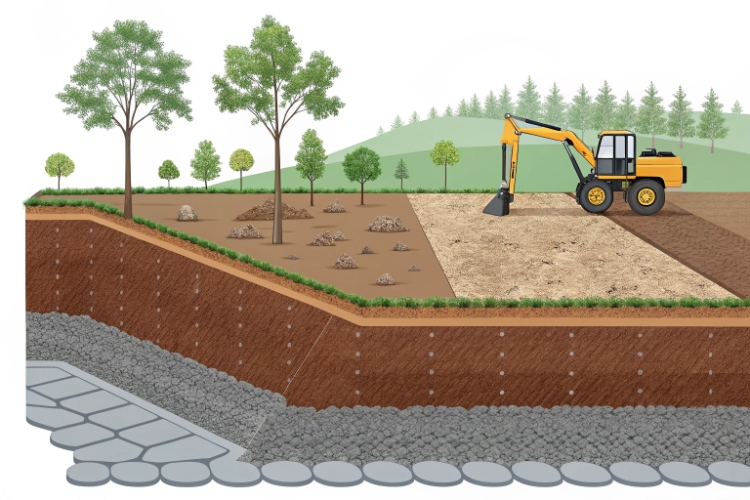

Under what ground or soil conditions is geotextile usually required?

The ground on your site looks firm enough. But is it? Seasonal rain or unexpected loads can turn seemingly stable soil into a problem, causing your entire project to sink or settle unevenly.

Geotextile is almost always required on soft, weak, or saturated soils. This includes soft clays and silts with low load-bearing capacity (a CBR value below 3-5), sites with a high water table, or areas with problem soils.

Reading the Ground

A geotechnical engineer will give you the precise data, but as a project manager or importer, you need to know the red flags. The soil itself tells you when geotextile is necessary. I always ask my clients about their site conditions before confirming an order.

-

Weak Soils (Low CBR)

The California Bearing Ratio (CBR) is a simple test that measures soil strength. A CBR value below 3 indicates very weak soil, like a soft clay. A value between 3 and 5 is still considered poor. Building a road or structure on this type of ground without a reinforcement geotextile is a recipe for failure. The fabric spreads the load, preventing the structure from sinking into the weak subgrade. -

Wet and Saturated Soils

If your site has a high water table or is just naturally swampy, you have two problems: the soil is weak, and fine particles will move with the water. A geotextile addresses both. A woven type can provide reinforcement, while a nonwoven type is essential for filtration to stop your expensive drainage aggregate from becoming contaminated with mud. -

Problematic Soils

Some soils create issues over time. Expansive clays swell when wet and shrink when dry, cracking foundations. Soils in cold climates heave and settle during freeze-thaw cycles. In both cases, a geotextile helps to stabilize the soil and mitigate these movements.

Which types of projects typically benefit from using geotextile fabric?

You're bidding on a big infrastructure project. Is geotextile a mandatory component or just a "value-add" option? Forgetting to include it on certain projects can lead to a bid rejection or a failed structure.

Roads, railways, retaining walls, landfills, and erosion control systems are all projects where geotextiles are standard practice. In general, any project involving poor soil, heavy loads, or critical drainage requirements will benefit from using one.

Geotextile in Action

From my experience shipping to different sectors, I see geotextiles used everywhere. Once you understand the five functions, you start to see why they are indispensable in so many applications. Here are the most common project types that rely on them:

| Project Type | Primary Geotextile Function(s) | Why It's Necessary |

|---|---|---|

| Roads, Railways, Airports | Separation, Reinforcement | Prevents the aggregate base from mixing with the soft subgrade soil. Spreads traffic loads to reduce rutting and extend the pavement's life. |

| Landfill & Containment | Protection, Filtration, Drainage | Acts as a cushion to protect the fragile geomembrane from punctures. Also used in drainage layers to prevent clogging. |

| Retaining Walls | Filtration, Reinforcement | Placed behind the wall to let water escape without washing out the backfill soil. Can also be layered within the backfill to reinforce it. |

| Erosion Control (Slopes, Shorelines) | الترشيح والفصل | Holds soil in place under riprap or other armor, allowing water to drain out without causing erosion. |

| Drainage Systems (French Drains) | الترشيح | Wraps around the drainage pipe and gravel, preventing surrounding soil from washing in and clogging the entire system. |

When can a project safely proceed without geotextile and still maintain performance?

Every project manager wants to optimize costs. So, when is it truly safe to skip the geotextile? Making this call requires certainty, because if you're wrong, the repair costs will dwarf the initial savings.

You can safely omit geotextile only when you have strong, stable, and well-drained subgrade soil (CBR ≥ 8) and the application involves low loads. For minor landscaping or temporary paths on firm ground, it may not be necessary.

Knowing When to Say No

While I sell geotextiles, I also advise clients when they might not need them. Honesty builds trust. A project can proceed without geotextile under a specific set of ideal conditions. If your site does not meet all of these criteria, then using a geotextile is the safer and more professional choice.

Conditions for Omitting Geotextile:

- Excellent Subgrade Soil: The ground must be naturally strong and stable. We're talking about well-compacted sand and gravel with a high load-bearing capacity (CBR of 8 or higher).

- No Water Problems: The site must be well-drained with a low water table. There should be no risk of the ground becoming saturated and weak during rainy seasons.

- Stable Climate: Areas without extreme freeze-thaw cycles are less prone to soil heaving and settling, reducing the need for reinforcement.

- Low-Stakes Application: For a simple garden path or a very temporary access road for light vehicles, some settlement might be acceptable. However, for any permanent structure, road, or critical application, the risk is too high.

Even in these cases, the cost-benefit analysis often still favors using a geotextile. The upfront cost of the fabric (around $1 per square foot) is small compared to the 15-25% increase in long-term maintenance costs that comes from rutting and settlement.

خاتمة

Geotextile isn't just fabric; it's insurance for your project's stability and longevity. Omitting it in anything but perfect soil conditions is a gamble that rarely pays off in the construction world.