An MSW landfill is an engineered containment system, and its liner is the single most important defense against environmental contamination. A liner failure isn't just a leak; it's a long-term liability that can pollute groundwater and soil for decades, leading to immense cleanup costs and regulatory penalties.

This guide provides a professional framework for selecting the right geomembrane liner for your Municipal Solid Waste (MSW) landfill. We will cover the key performance requirements, compare common liner solutions like HDPE and composite systems, and outline a decision-making process that prioritizes long-term security over short-term costs.

ك manufacturer and supplier of geosynthetics, I've worked on landfill projects worldwide. The most successful ones all have one thing in common: they treat the liner system not as a commodity, but as a critical, long-term investment in environmental protection and operational security. This guide shares the practical insights gained from that experience.

Why Liner Selection Is Critical for MSW Landfills

The primary purpose of a landfill liner is to contain leachate—the contaminated liquid that forms as rainwater trickles through waste—and prevent it from escaping into the environment. A well-designed liner system is the foundation of modern landfilling, and selecting the right materials is not a step to be taken lightly.

Regulatory bodies globally have set strict standards for this reason. In the U.S., the EPA’s 40 CFR 258 regulations mandate the use of composite liner systems for MSW landfills. China's GB 16889 standard outlines similar stringent requirements. These rules exist because the long-term risks are so high. A compromised liner can lead to groundwater contamination plumes that are incredibly difficult and expensive to remediate. Studies of modern landfills show that well-designed composite systems can achieve over 98% leachate collection efficiency, demonstrating the effectiveness of proper engineering.

Key Performance Requirements for MSW Landfill Liners

When evaluating liner materials, you are not just buying a roll of plastic; you are specifying a set of performance characteristics. Any geomembrane destined for an MSW landfill must excel in these key areas.

Chemical Resistance to Leachate

MSW leachate is an aggressive chemical cocktail that changes over time. It can contain a wide range of organic and inorganic compounds, acids, and alkalis. The liner material must be able to withstand this constant chemical-attack for decades without degrading. This is the single most important property for long-term containment.

Low Permeability

The fundamental job of a liner is to be a barrier. The material must have an extremely low hydraulic conductivity (permeability) to ensure that the rate of liquid migration through the liner is negligible. This prevents contaminants from seeping into the subgrade even under the hydraulic pressure of the leachate head.

Long-Term Durability

A landfill has an operational life and a post-closure monitoring period that can span 30 to 50 years or more. The liner must maintain its integrity throughout this entire lifespan, resisting aging and degradation from biological activity, chemical exposure, and temperature fluctuations. We design our highest-grade materials with lifespans projected to exceed 100 years under typical landfill conditions.

مقاومة الإجهاد الكراك

Landfills settle. The waste load and underlying soils will shift and consolidate over time, placing immense stress on the liner. The geomembrane must have excellent Environmental مقاومة الإجهاد الكراك (ESCR) to resist cracking and failure when subjected to these long-term tensile strains.

UV and Thermal Performance

During installation, the geomembrane is exposed to sunlight and daily temperature cycles. The material must have sufficient UV stabilization to prevent degradation from sun exposure before it is covered. It also needs to handle thermal expansion and contraction without being damaged, which is critical for achieving high-quality seams during field welding.

Common Liner Solutions Used in MSW Landfills

Based on the performance requirements, the industry has standardized on a few highly effective liner solutions.

HDPE Geomembrane Liners

البولي إيثيلين عالي الكثافة (HDPE) is the undisputed material of choice for MSW landfill liners worldwide. Its molecular structure gives it a superior combination of the key performance characteristics we just discussed.

- Advantages: HDPE offers exceptional chemical resistance across a broad pH range, making it ideal for aggressive leachate. It has extremely low permeability, high tensile strength to withstand installation stresses, and excellent long-term durability. Because it can be produced without plasticizers or other additives that might leach out over time, its performance is stable and predictable.

- Common Thickness: For the primary bottom liner in an MSW landfill, the standard thicknesses are 1.5 mm (60 mil) and 2.0 mm (80 mil). While thinner options exist for temporary caps or less critical applications, the added puncture resistance and durability of a 1.5 mm or 2.0 mm sheet provide a critical margin of safety for permanent containment.

- القيود: HDPE requires specialized welding equipment and certified technicians for proper installation. The quality of the field seams is just as important as the quality of the material itself.

Composite Liner Systems

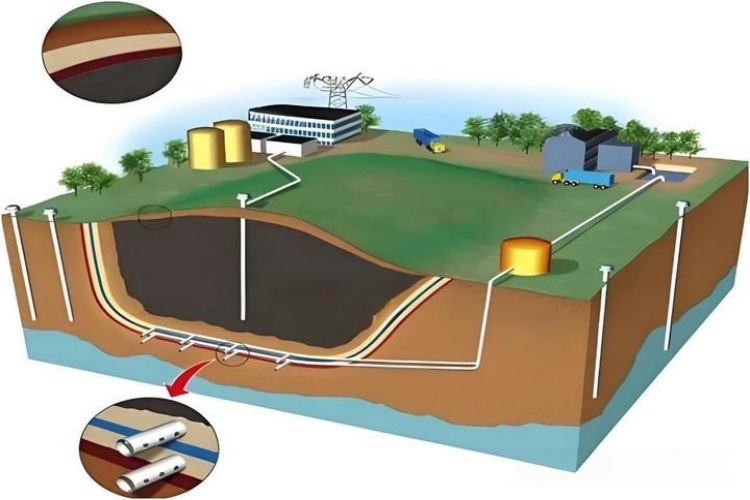

أ composite liner is not just a single material, but a system that combines an HDPE geomembrane with a low-permeability soil layer. This combination provides a level of protection that is far greater than either component alone.

This is the standard design for modern MSW landfills. The system typically consists of an HDPE geomembrane placed directly on top of either:

- أ بطانة الطين الاصطناعية (GCL): A GCL is a factory-made composite of bentonite clay sandwiched between two geotextiles. It's a modern, efficient alternative to thick clay layers, offering low permeability and self-healing properties for minor punctures.

- A Compacted Clay Liner (CCL): A traditional CCL is a thick layer (e.g., 0.6 m or 2 ft) of natural clay, compacted on-site to achieve a very low permeability.

The magic of the composite liner is that the two layers work together. If a small defect exists in the HDPE geomembrane, the underlying GCL or CCL severely restricts the flow of leachate, preventing a small leak from becoming a large one.

How to Choose the Right Liner Solution for Your MSW Landfill

Choosing the right liner is a site-specific engineering decision. Rather than having a default "go-to" product, you should evaluate these factors to build the optimal solution for your project.

- Site Conditions: The local hydrogeology is paramount. Is the landfill located over a sensitive aquifer? Is the water table high? More sensitive environments demand more robust protection, often leading to the selection of a double composite liner system.

- Waste Characteristics: While this article focuses on MSW, the type of waste makes a difference. A landfill accepting industrial sludge or other more concentrated wastes may require thicker liners or even more chemically resistant materials.

- Regulatory Expectations: Always start with your local, state, and national regulations. These will define the minimum acceptable standard. However, it's often wise to engineer a system that exceeds the minimum requirement to build in a factor of safety and future-proof the facility.

- Installation Environment: Consider the climate. In very hot or cold climates, the liner's thermal expansion and contraction properties become more critical for achieving good welds. The size and geometry of the landfill cell can also influence material choices and panel layout.

- Project Lifespan: Consider the full lifespan, including the 30-year post-closure care period. The liner you choose today must perform reliably for the entire duration. This perspective forces a focus on long-term durability over initial material cost.

تثبيت & Quality Considerations That Affect Product Performance

Even the best geomembrane material in the world will fail if it's installed incorrectly. The performance of the final liner system is a product of both material quality and installation quality.

Subgrade preparation must be perfect, free of stones or sharp objects. Panels must be deployed without damage, and every inch of the welded seams must be tested and verified. This requires a rigorous Construction Quality Assurance (CQA) plan executed by experienced professionals. The welding process, destructive seam testing, and non-destructive testing are all critical steps that ensure the individual panels become a single, monolithic barrier.

(We've covered the specifics of this in a previous article. For a detailed checklist, you can refer to our guide: "Field Quality Control Checklist for Landfill Geomembrane Installation.")

Why Material Quality Matters More Than Initial Cost

In B2B purchasing, it’s easy to focus on the upfront unit price. For landfill liners, this is a dangerous trap. The material cost of the geomembrane is a small fraction of the total landfill construction cost, and an even smaller fraction of the potential cost of a liner failure.

- Failure Cost: The cost to remediate a groundwater contamination plume can run into the millions of dollars.

- Repair Difficulty: Repairing a leak in a bottom liner once waste is in place is extraordinarily difficult, disruptive, and expensive, often requiring massive excavation.

- Long-Term Liability: An underperforming liner creates a liability that stays with the owner for decades, impacting financial standing and corporate reputation.

This is why specifying high-quality material is non-negotiable. Choosing a proven geomembrane manufacturer that uses 100% virgin resin and can certify that their product meets or exceeds industry standards like GRI GM13 is the most effective risk management strategy you can employ. The small premium for a top-tier product is insignificant compared to the cost of the risks it mitigates.

Summary: Selecting a Reliable Liner Solution for MSW Landfills

To provide a clear starting point, here are the most common and reliable liner system configurations for MSW landfills.

| Configuration Level | Liner System Structure | HDPE Geomembrane Thickness | Secondary Barrier | Typical Application |

|---|---|---|---|---|

| Standard Configuration | Single Composite Liner | 1.5 mm (60 mil) to 2.0 mm (80 mil) | GCL or 0.6m Compacted Clay Liner (CCL) | Most standard MSW landfills meeting modern regulations. |

| Enhanced Configuration | Double Composite Liner | Primary: 1.5-2.0 mm Secondary: 1.5 ملم |

Both primary and secondary liners are placed on GCLs or CCLs. A leak detection layer is placed between them. | Highly sensitive environments, high water tables, or landfills accepting more hazardous waste. |

خاتمة

Ultimately, selecting a geomembrane for an MSW landfill is an investment in certainty and long-term security. The ideal solution, a composite system featuring a 1.5 mm or 2.0 mm HDPE geomembrane from a reputable manufacturer, provides a robust and reliable barrier. By prioritizing performance requirements and total cost of ownership over initial price, you ensure regulatory compliance, protect the environment, and safeguard your organization from future liability.