You're trying to build on weak, unstable soil. You worry that your road will rut, your embankment will slump, or your slope will fail. Traditional solutions like excavating and replacing the soil are incredibly slow and expensive.

Geotextiles provide reinforcement by adding tensile strength to the soil, turning it into a strong composite material. This allows the ground to carry heavier loads, resist deformation, and remain stable for the long term, often at a lower cost than traditional methods.

As a supplier, I've seen clients transform difficult sites into solid foundations using this technology. Soil is strong when you compress it but pulls apart easily. Geotextiles are the opposite—they are incredibly strong when you pull on them. By combining the two, you create a system that is stronger than the sum of its parts. Let's break down exactly how this simple-looking fabric works its engineering magic.

How do geotextiles improve soil strength and load-bearing capacity?

You have weak soil that can't support the weight of your planned structure. You are worried about building on it, fearing costly settlement or a complete bearing failure. How can a thin fabric possibly solve this big problem?

Geotextiles act like steel rebar does in concrete. By creating friction with soil particles, the fabric adds the tensile strength that soil naturally lacks. This turns the soil and fabric into a single, stronger composite system, increasing its load-bearing capacity by 30-50%.

Creating a Stronger Composite

Think of soil as a pile of loose bricks. It can hold a lot of weight if you press straight down (compression), but it crumbles and spreads if you push it from the side. A geotextile fabric, especially a woven one, is like the rebar and mortar that holds those bricks together. It has immense tensile strength. When it’s placed in the soil, the soil particles lock onto its surface through friction. This is called interfacial friction. When a load is applied, the geotextile's tensile strength prevents the soil particles from sliding and moving apart. The soil is now "reinforced" and behaves like a cohesive slab, not a pile of loose particles. This composite action is the key to creating a foundation that can safely support much heavier loads.

What mechanisms allow geotextiles to control deformation and enhance stability?

Your road keeps developing ruts, or the side of an embankment is slowly slumping. You need to stop this movement, but constant repairs are draining your budget. What is actually happening in the ground, and how can a geotextile stop it?

Geotextiles control deformation through two key mechanisms. First, they act as a membrane to distribute loads over a wider area. Second, they redirect the soil's natural failure plane, forcing it to find a stronger path and preventing slip failures.

From my experience, understanding these two effects helps clients see why reinforcement works so well.

-

The Membrane Effect

Imagine walking on deep snow. Without snowshoes, you sink. With snowshoes, your weight is spread over a larger area, and you stay on top. A geotextile does the same thing for a truck tire on a soft road. The fabric’s tension distributes the concentrated wheel load across a much broader section of the weak subgrade. This reduces stress at any single point, preventing the soil from deforming and creating ruts. This mechanism alone can reduce uneven settlement by over 30%. -

Repositioning the Failure Plane

When soil fails under a load, it does so along its weakest natural path—the path of least resistance. A geotextile physically blocks this path. Because the fabric is so strong in tension, the soil can't shear through it. Instead, the failure is forced to occur along a different, longer, and stronger path. This requires much more energy, which means the entire system has a higher overall strength and is more stable.

In what types of structures are geotextile reinforcement most effective?

You know geotextiles can reinforce soil, but you aren't sure where they provide the most value. You see them specified for roads, walls, and slopes, and wonder how one product can do so many jobs.

Geotextile reinforcement is most effective in unpaved haul roads, the base course of paved roads, steep soil embankments, and retaining walls. In these applications, it drastically improves stability while reducing the need for expensive materials and complex construction.

While the applications are diverse, they all rely on the same reinforcement principles. Here are the most common uses I supply materials for:

-

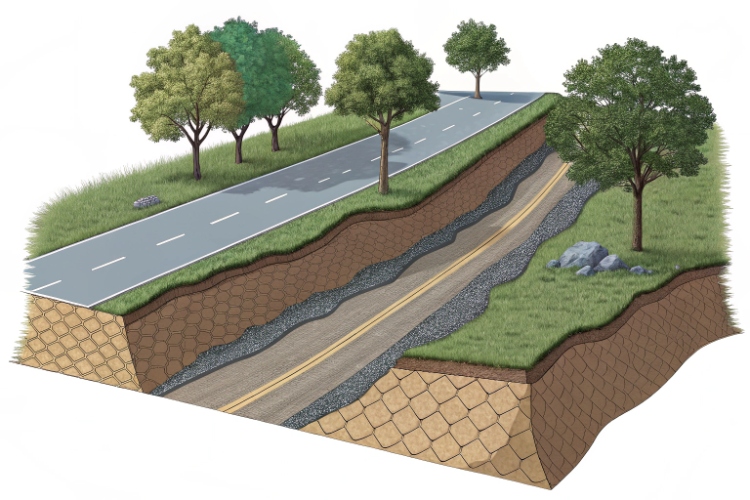

Roads and Pavements

For unpaved roads on soft ground, geotextiles are a game-changer. They prevent the gravel from being lost in the mud and reduce rutting by over 40%. For paved roads, placing a geotextile in the base course creates a stiffer foundation. This allows engineers to reduce the thickness of the expensive aggregate layer by up to 25% while achieving the same performance, saving a lot of money on materials and transport. -

Embankments and Slopes

By placing horizontal layers of high-strength geotextile within a soil slope as it's built, you can safely construct much steeper slopes than with unreinforced soil. I've seen clients build stable embankments at 45 degrees or more, something that would be impossible otherwise. The geotextile layers act like internal shelves, holding the soil mass together and improving the stability factor by over 35%. -

Wrapped-Face Retaining Walls

Instead of building a costly concrete wall, you can build a stable retaining wall using soil and geotextiles. The geotextile layers extend back into the soil to provide stability, and the front face is simply wrapped up to contain the soil. These walls are flexible, cost-effective, and often support vegetation for a green, natural look.

How can I select the right geotextile strength and type for reinforcement applications?

You're ready to use a geotextile for reinforcement, but your supplier offers dozens of options. There are woven and nonwoven fabrics, with tensile strengths from 20 kN/m to over 300 kN/m. Choosing wrong could mean your structure fails.

For reinforcement, you almost always need a high-strength woven geotextile. Its high tensile strength and low elongation provide the stiffness needed to restrain the soil. The specific strength required is determined by an engineer and depends on the application's load.

When a client wants to reinforce something, my first piece of advice is always to look at woven fabrics. Here’s why and what to look for:

| Geotextile Type | Primary Use Case | Why It's Chosen |

|---|---|---|

| التكسية الأرضية المنسوجة | تعزيز | High tensile strength (strong when pulled) and low elongation (doesn't stretch much). This provides the stiffness needed to lock soil in place and carry loads. |

| الجيوتكستيل غير المنسوج | الترشيح & الصرف الصحي | High permeability (lets water through easily) and a felt-like structure that is perfect for filtering soil particles. It stretches too much to be an effective reinforcer. |

For reinforcement, the most important property on a data sheet is Ultimate Tensile Strength, measured in kilonewtons per meter (kN/m). A stronger fabric provides more reinforcement. A geotextile for a heavy-duty embankment might need over 200 kN/m, while a simple road base might only require 50 kN/m. Just as important is Creep Resistance—the ability to hold a load over many years without slowly stretching and failing. Always ensure the product is designed for long-term reinforcement.

خاتمة

Geotextile reinforcement is a proven engineering solution that adds tensile strength to soil. It creates a durable composite material, enabling construction on weak ground, saving costs, and ensuring long-term structural stability.