Building a landfill with just a single liner is risky. One small puncture could let toxic leachate escape into the groundwater. This could lead to an environmental disaster and huge financial penalties that could ruin a company.

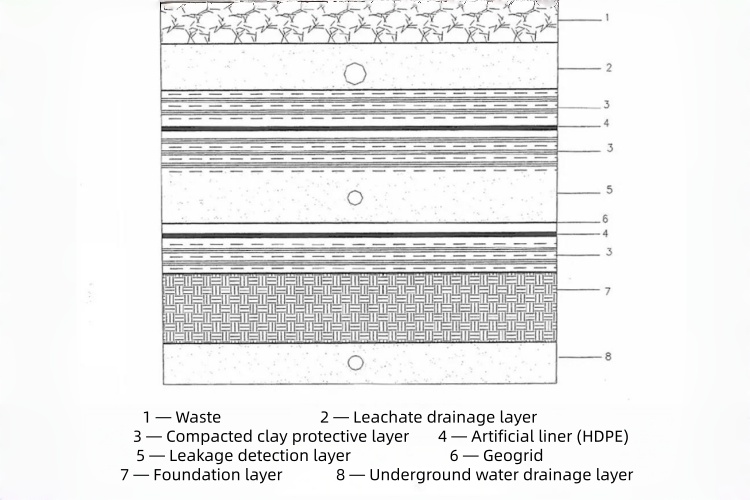

A double-lining system is an advanced barrier with two separate liners: a primary and a secondary. A leak detection layer sits between them. This design gives you redundancy and an early warning if the top liner fails, keeping contaminants contained.

As a geosynthetics supplier, I often explain to my clients that a double-liner isn't just two sheets of plastic. It's a precisely engineered system where every single layer has a critical job. It’s the gold standard for a reason. To see why this system offers the best protection, you have to understand how all the parts work together as a team. Let's break it down.

What components typically make up a double-lining system in modern landfill engineering?

Looking at a landfill design, you know there are two liners. But what about all the other layers? The drainage nets, collection pipes, and clay liners are all essential parts that make the entire system function correctly.

A complete double-lining system is a multi-layered structure of geosynthetics and soil. It includes a primary liner, a primary leachate collection system, a secondary liner, and a leak detection system, all resting on a compacted base.

From my experience shipping these materials worldwide, this is the most common configuration that meets strict environmental regulations. Here is a detailed breakdown of a complete system, from top to bottom, with the technical specifications I always discuss with my clients.

| Layer Order | Component | Function | Common Material Specifications |

|---|---|---|---|

| Optional | Protective Cover Layer | Protects the liner system from damage and controls water infiltration. | Soil or natural vegetation. |

| Layer 1 | Primary Liner (FML) | The main barrier that stops leachate from migrating downwards. It is in direct contact with the waste. | 1.5–2.5 mm High-Density Polyethylene (HDPE) geomembrane. |

| Layer 2 | Primary Leachate Collection System | Rapidly drains leachate from the waste to keep liquid pressure on the liner low (≤ 300 mm). | 10–50 mm thick geonet or drainage geocomposite, plus 150 mm diameter perforated PVC or HDPE pipes. |

| Layer 3 | Secondary Liner (FML or Composite) | The backup barrier. It contains any liquid that might leak through a defect in the primary liner. | 1.5–2.5 mm HDPE geomembrane, or an HDPE/GCL composite liner. |

| Layer 4 | Leak Detection System (LDRS) | Detects, collects, and removes any liquid that breaches the primary liner, providing an early warning. | Geonet or drainage geocomposite, with its own dedicated detection pipes. |

| Layer 5 | Foundation / Subgrade Liner | The final line of defense to protect the native soil and groundwater. | 2–5 meters of compacted clay (permeability ≤ 1x10⁻⁷ cm/s) or a Геосинтетический глиняный вкладыш (GCL). |

| Layer 6 | Prepared Subgrade | The native soil foundation for the entire system. | In-situ soil. |

There are also variations to this design. The most common is the FML/composite double-liner, which is the standard recommended by the US EPA for hazardous waste. Other designs, like those seen in Florida, use a Geosynthetic Clay Liner (GCL) under the secondary geomembrane. The GCL has a self-sealing property, which allows it to seal around small punctures, adding another layer of security.

How does each layer in a double-lining system function to prevent leachate migration?

You see the list of components, but how do they function as a team? A liner alone is just a sheet of plastic. Its real power comes from the drainage and detection layers that work with it.

Each layer plays a specific role. The primary system collects the leachate, the leak detection layer acts as a 24/7 monitor, and the secondary system provides failsafe containment. This teamwork ensures unmatched environmental protection.

Let's look at how this multi-barrier defense works in practice. The primary leachate collection system isn't just a random drainage layer. It's engineered with a specific hydraulic transmissivity (the ability to move liquid) of at least 0.3x10⁻³ m²/s. It also has collection pipes spaced no more than 25 meters apart, on a slope of at least 1% to 3%. This design removes leachate quickly, which dramatically reduces the pressure on the primary liner. Below this, the leak detection layer is always ready. If any liquid appears in its dedicated sump, it's a clear signal that the primary liner has a problem. This allows the landfill operator to act before it becomes a major environmental issue. The long-term superiority is clear when you compare it to a single-liner design.

| Особенность | Single-Liner System | Double-Liner System |

|---|---|---|

| Containment Performance | Relies on one liner. A single defect means total failure. | Provides two independent lines of defense for high redundancy. |

| Leak Detection | Micro-punctures are nearly impossible to find after installation. | The secondary system provides immediate and certain detection of a breach. |

| Head Control | If the liner is breached, leachate pressure increases, forcing more liquid out. | Even if the primary liner is breached, the secondary liner protects groundwater. |

| Groundwater Protection | Depends on a 100% defect-free liner, which is not realistic. | Risk is drastically reduced even with minor liner defects. |

| Cost | Lower initial cost. | 20% to 40% higher initial cost. |

| Regulatory Requirement | Permitted only for some standard municipal solid waste landfills. | Mandatory for hazardous waste; recommended for all high-risk sites. |

| Long-Term Maintenance | Reactive repairs are difficult and expensive. | The detection system allows for proactive and targeted maintenance. |

In which landfill conditions is a double-lining system required?

Given the higher cost, you might think this system is overkill. The choice depends entirely on the level of risk from the waste and the sensitivity of the local environment.

A double-lining system is mandatory for landfills containing hazardous waste. It is also the required standard for most new municipal solid waste (MSW) landfills, especially if they are in environmentally sensitive areas.

Regulators like the U.S. Environmental Protection Agency (EPA) mandate double-lining systems under rules like Subtitle C for a simple reason: the risk of failure with hazardous waste is too high. If you are designing a facility for any of the following, a double-lining system isn't just a recommendation—it's a requirement.

- Hazardous Waste Landfills: The contents are toxic. Any leak is unacceptable, making double-liners a legal necessity.

- High-Risk Municipal Solid Waste (MSW) Landfills: Waste from large cities can contain household hazardous materials. Regulators often require double-liners here for an extra margin of safety.

- Landfills Near Sensitive Aquifers: If a landfill is located over a source of drinking water or a vulnerable ecosystem, a double-lining system is the only way to guarantee protection.

- Leachate Ponds and Industrial Lagoons: Any pond designed to hold concentrated toxic liquids almost always requires a double-lined system for primary and secondary containment.

Ultimately, the decision is about risk. For low-risk waste in a dry, stable area, a single composite liner might be enough. For everything else, the double-lining system is the benchmark for safe, modern landfill design.

How can I evaluate the effectiveness and long-term reliability of a double-lining system?

You’ve invested in this advanced system. How do you know it's still working perfectly five or ten years later? The answer is built right into the design: the monitoring capability of the leak detection layer.

You evaluate a double-lining system's effectiveness by monitoring the liquid flow rate from the leak detection layer. A consistent zero or near-zero flow confirms the primary liner is intact. A sudden spike in flow is immediate proof of a breach.

The leak detection system is more than just a backup; it's a diagnostic tool. Each section of this layer drains to a separate collection point, or sump, which is equipped with a pump and a flow meter. This instrumentation gives you constant, measurable data on your primary liner's performance. You can see a problem the moment it happens. In the industry, we have a general rule of thumb for what constitutes an alarm. If the flow rate in the leak detection layer suddenly reaches about 1% of the flow rate in the primary collection layer, it signals an anomaly that needs to be investigated. For example, if your primary system collects 5,000 liters per day, and the detection system suddenly shows 50 liters per day, you know you have a problem. This early warning system allows for proactive, targeted maintenance, saving massive costs and preventing environmental damage down the line.

Заключение

A double-lining system offers unparalleled landfill security. Its redundant layers and built-in leak detection provide a robust, verifiable barrier that protects groundwater and ensures long-term environmental compliance for any high-risk containment project.