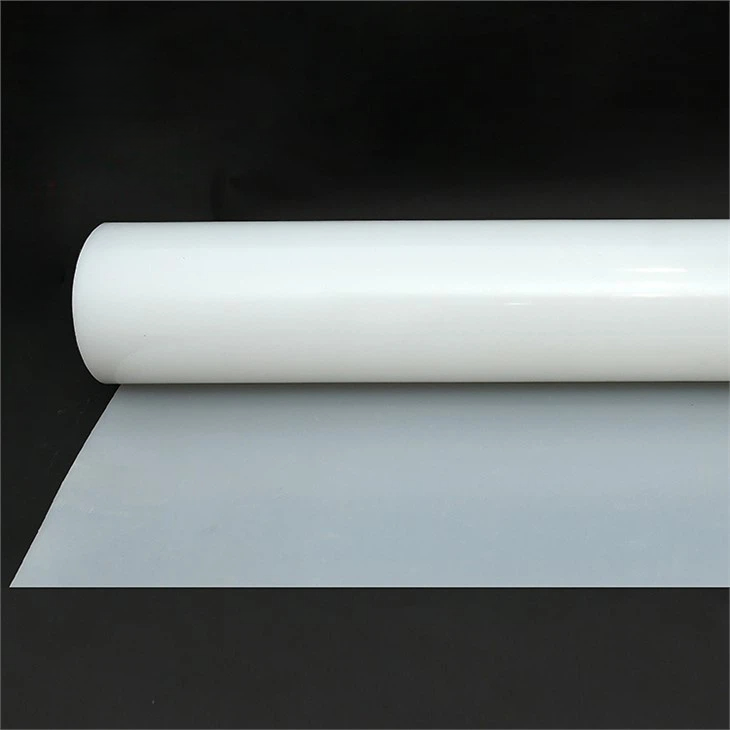

PVC Geomembrane — Flexible Waterproof Liner for Construction & Environmental Projects

Polyvinyl chloride (PVC) geomembrane liners for construction, environmental, and waterproofing projects. Smooth or textured, 0.5–3.0 mm, factory-direct supply worldwide.

ASTM/GRI/ISO-Reference

Factory Directly

Export Global

Properties of PVC Geomembrane

PVC geomembrane remains flexible even in low-temperature environments (-20℃ to -40℃), without becoming brittle.

With an elongation rate of 300%–500%, PVC geomembrane can adapt to uneven settlement and deformation, reducing the risk of cracks caused by ground movement.

Stabilized with UV and antioxidant additives, PVC geomembrane offers reliable weathering and anti-aging performance, with a service life of 20+ years.

PVC geomembrane supports hot-air or high-frequency welding, ensuring high seam strength and excellent impermeability.

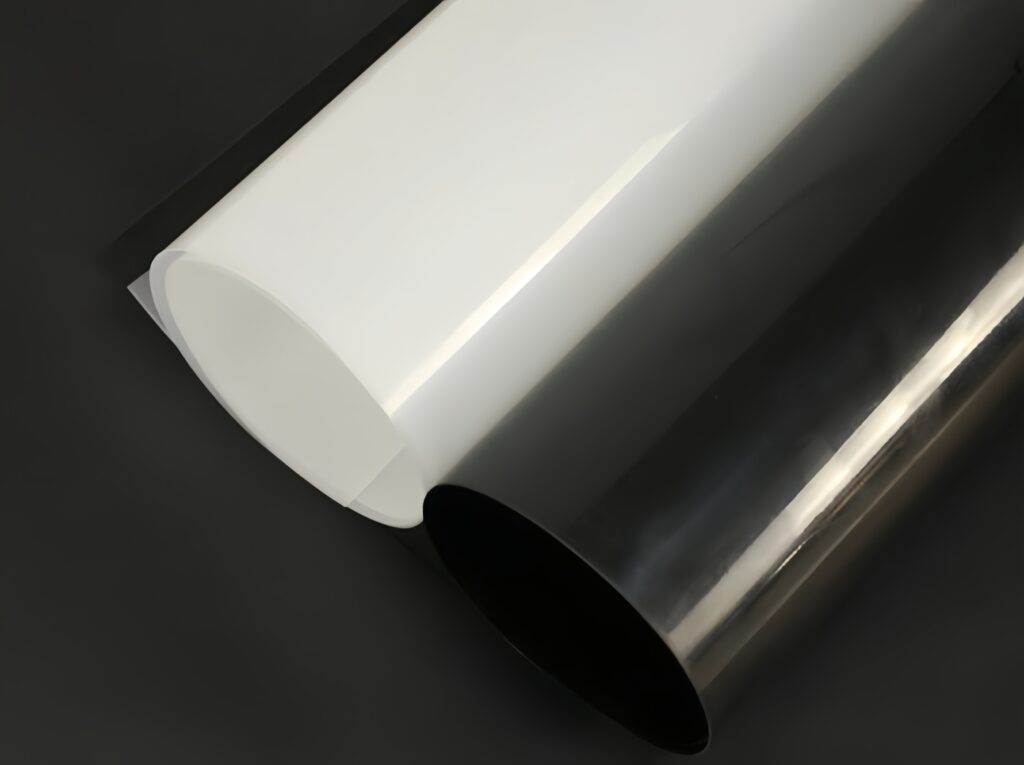

PVC geomembrane can be produced in transparent or opaque types. Transparent liners allow light penetration, useful for agriculture or solar-related projects.

Compared with HDPE geomembrane, PVC offers better flexibility and welding performance at a lower cost, delivering excellent cost-effectiveness.

Get to Know PVC Geomembrane

PVC geomembrane is a flexible, impermeable liner made from polyvinyl chloride resin with added plasticizers and stabilizers. It is widely used for waterproofing and anti-seepage applications in civil, agricultural, and construction projects.

PVC geomembrane material is based on polyvinyl chloride, blended with UV stabilizers, antioxidants, and eco-friendly plasticizers. Compared with HDPE, it offers higher flexibility and easier welding, making it ideal for underground and roofing waterproofing.

Typical PVC geomembrane thickness ranges from 0.5 mm to 3.0 mm. Standard sizes include 0.75 mm, 1.0 mm, 1.5 mm, and 2.0 mm, available in rolls or sheets up to 8 meters wide.

Yes, PVC geomembrane is an impermeable liner with very low permeability. It provides reliable waterproofing for basements, tunnels, reservoirs, and ponds.

PVC geomembrane is mainly used for seepage control and waterproofing in multiple industries:

Water conservancy projects: reservoirs, dams, canals

Environmental engineering: landfill covers, sewage treatment ponds

Building waterproofing: basements, roofs, tunnels

Agricultural projects: aquaculture ponds, irrigation canals

Landscape engineering: artificial lakes, decorative ponds

⚠️ Not recommended for:

Extreme low-temperature conditions (below -40℃)

Long-term contact with highly corrosive chemicals

The service life of PVC geomembrane is typically 15–25 years, depending on thickness, installation quality, and exposure conditions. In underground or covered projects, lifespan can be even longer.

Color Options of PVC Geomembrane

Surface: PVC geomembrane is typically produced with smooth surfaces for easy cleaning and welding. Textured options are available on request for projects requiring extra friction.

Colors:

Gray PVC geomembrane – commonly used in underground waterproofing and roofing.

Black PVC geomembrane – general waterproofing applications.

White PVC geomembrane –reflects sunlight, helps reduce surface temperature, suitable for hot climates and projects requiring thermal control.

PVC Geomembrane Thickness Guide & Applications

| Thickness (mm) | Key Performance Features | Typical Applications | Recommended Specs & Notes |

|---|---|---|---|

| 0.50 mm PVC geomembrane sheet |

Basic impermeability, high flexibility, adapts to complex ground | Small ecological ponds, farmland canals, temporary water storage | Use with nonwoven geotextile protection; avoid direct contact with sharp loads |

| 0.75 mm PVC geomembrane roll |

Improved impermeability, medium puncture resistance, good UV resistance | Aquaculture ponds (PVC geomembrane pond liner), small drainage ditches, low-slope embankments | Single-textured option available; can be laid directly on flat foundations |

| 1.00 mm Standard PVC geomembrane thickness |

Common choice, cost-effective, strong impact & puncture resistance | Agricultural irrigation & drainage systems, small landfill leachate ponds, municipal stormwater reservoirs | Smooth or textured PVC geomembrane; recommend sand cushion or geotextile isolation |

| 1.20 mm PVC geomembrane liner |

Good puncture resistance, better chemical and aging resistance | Sewage treatment ponds, basement waterproofing, tailings dam base lining | Combine with geotextile for extra protection; place textured surface against soil for slope stability |

| 1.50 mm PVC geomembrane sheet |

High tensile strength, resistant to impact and root penetration | Medium-size landfill sidewalls (PVC geomembrane for landfill), large tailings ponds, chemical waste ponds | Double-textured PVC geomembrane recommended for 5–15° slopes; seams require strict leak detection |

| 2.00 mm PVC geomembrane roll |

Engineering-grade thickness, high puncture & chemical resistance, withstands UV and high temperatures | Large sludge ponds, hazardous waste containment, high-temperature exposed environments | Use with high-strength geotextile for multi-layer anti-seepage; automated welding recommended |

| 2.50–3.00 mm Heavy-duty PVC geomembrane liner |

Extreme performance, superior puncture resistance, crack propagation resistance, long service life | Nuclear waste storage, deep foundation waterproofing, large industrial tailings dams | Multi-layer reinforced PVC geomembrane; requires professional installation; service life 30+ years |

PVC Geomembrane Specifications, Testing & Data Sheet

| Property | Test Method (ref.) | Typical Value / Min | Note |

|---|---|---|---|

| Density | ASTM D1505 | 1.20–1.35 g/cm³ | PVC geomembrane density |

| Tensile Strength | ASTM D638 | ≥ 15–20 MPa | strength of PVC geomembrane sheet |

| Elongation at Break | ASTM D638 | ≥ 300%–500% | high flexibility, adapts to settlement |

| Tear Resistance | ASTM D1004 | ≥ 80 N | tear resistance of PVC liner |

| Puncture Resistance | ASTM D4833 | ≥ 200 N | impact & puncture resistance |

| Carbon Black / Additives | ASTM D4218 | 2–3% (if black) | UV stabilizers for outdoor PVC geomembrane |

| Dimensional Stability | ASTM D1204 | ±2% | thermal stability during installation |

| Water Permeability | ASTM D5084 | ≤ 1.0 × 10⁻¹³ cm/s | PVC geomembrane impermeability |

| Service Temperature | — | -20℃ to +60℃ | operating range of PVC geomembrane liner |

PVC Geomembrane Installation,Welding & CQA

Welding Methods

PVC geomembranes are thermoplastic materials, which means they can be welded using heat-based methods to create strong, watertight seams. Below are the commonly used welding techniques:

Hot Air Welding

Ideal for PVC materials, especially in field applications. This method uses a stream of hot air to heat the seam surfaces and a roller to press them together. It is suitable for detailed work and small repairs.Solvent Welding

Commonly used for factory seams or prefabricated panels. A chemical solvent softens the surface of the PVC, allowing it to fuse without added heat. This method ensures molecular bonding but requires controlled conditions.Wedge Welding (Modified for PVC)

Less common than with HDPE, but some installers use modified wedge welders with lower temperatures to create continuous seams for large-scale PVC liner installations.Extrusion Welding (Not Recommended for PVC)

Unlike HDPE, extrusion welding is not typically recommended for PVC geomembranes due to the material’s sensitivity to high heat and risk of degradation.

Seam Preparation & Overlap Requirements

Surface Cleaning: PVC sheets must be dry, clean, and free of dust, oil, or debris before welding. Use lint-free cloths and PVC-safe cleaning agents.

Overlap Width: A minimum overlap of 100–150 mm (4–6 inches) is required to ensure proper fusion and leak-free joints.

Tacking: Temporary tacking with hot air or light adhesive may be used before full seam welding to prevent misalignment in windy or uneven conditions.

Important Considerations for PVC Welding

Ambient Temperature: PVC welding is sensitive to ambient conditions. Optimal results are achieved between 5°C–35°C (41°F–95°F).

PVC Flexibility: PVC remains flexible in low temperatures, making it ideal for cold-weather installations compared to HDPE.

UV Protection: If exposed, consider using UV-stabilized PVC or cover with protective layers to prevent degradation over time.

HDPE vs PVC Geomembrane — Key Differences, Applications & Selection Guide

| Comparison Item | PVC Geomembrane | HDPE Geomembrane |

|---|---|---|

| Material Composition | Polyvinyl chloride resin with plasticizers, stabilizers, UV additives | High-density polyethylene resin with antioxidants and carbon black |

| Density | 1.30–1.45 g/cm³ | 0.941–0.965 g/cm³ |

| Tensile Strength | 25–35 MPa | 30–40 MPa |

| Elongation | 200–400% (high flexibility) | ≤ 500% |

| Static Puncture Resistance | 150–300 N (ASTM D4833) | 300–400 N (ASTM D4833) |

| Dynamic Impact Resistance | 800–1200 J (drop weight test) | 400–800 J |

| Tear Resistance | 120–200 N | 100–180 N |

| Chemical Resistance | Excellent, resistant to most acids, alkalis, and solvents | Outstanding, highly resistant to strong acids, alkalis, and oils |

| UV Aging Resistance | Good, requires stabilizers and additives | Excellent, high carbon black content provides long-term UV stability |

| Root Resistance | Moderate | Good |

| Service Temperature | –30℃ to +70℃ | –50℃ to +60℃ |

| Welding Method | Hot-melt welding, hot-air welding | Extrusion welding, hot wedge welding, fusion welding |

| Seam Strength | ≥ 80% of parent material | ≥ 90% of parent material |

| Installation Convenience | Easy to weld, flexible, conforms to complex structures | Rigid, requires preheating and professional welding equipment |

| Common Thickness Range | 0.5–2.0 mm | 0.5–3.0 mm |

| Common Colors | Black, white, gray, green (custom available) | Black (mainstream), white, green, blue (custom available) |

| Price Level | Medium | Higher |

| Service Life | 15–30 years | 25–50 years |

| Main Applications | Reservoirs, roofing waterproofing, landfill capping, basements, decorative ponds | Large hydraulic projects (dams, canals), chemical ponds, hazardous waste sites, tailings dams |

| Selection Recommendation | Best for flexibility, complex structures, and high dynamic impact areas | Best for high strength, static puncture resistance, and long-term exposed projects |

Why Choose WP Specialist?

Over the years, we have established ourselves among trusted PVC geomembrane manufacturers and global PVC geomembrane distributors. Our focus is on delivering reliable liners that meet critical engineering projects.

- Free Samples of PVC Geomembrane Sheet

- Expert Project Support

- Reliable Quality Assurance

- Over 10 Years of Manufacturing Experience

- Factory Direct Supply

Basics of Wholesale PVC Geomembrane

Please include project type (pond, landfill, mining, reservoir), required thickness, surface (smooth / textured), roll size preference, and delivery terms (FOB/CIF + port).

Yes, free PVC geomembrane sheet samples are available for evaluation prior to bulk purchase.

Typical lead time is 15–25 days for production, plus shipping schedule depending on destination port.

The standard roll width for export is 5.8 m, which is optimized for container loading. Longer widths such as 1–6 m are also available, depending on actual container loading conditions. Roll length usually ranges from 50–150 m, adjusted by thickness. Custom prefabricated panels can be supplied if required.

The weight of a PVC geomembrane liner is calculated by:

Weight (kg)=Thickness (mm)×Width (m)×Length (m)×Density (g/cm³)÷1000\text{Weight (kg)} = \text{Thickness (mm)} \times \text{Width (m)} \times \text{Length (m)} \times \text{Density (g/cm³)} \div 1000Weight (kg)=Thickness (mm)×Width (m)×Length (m)×Density (g/cm³)÷1000

👉 For example, a 1.0 mm PVC geomembrane roll (density ~1.35 g/cm³, size 7 m × 50 m):

1.0×7×50×1.35=472.5 kg/roll1.0 \times 7 \times 50 \times 1.35 = 472.5 \, kg/roll1.0×7×50×1.35=472.5kg/roll

Capacity is calculated based on 40HQ ≈ 25 tons loading weight. The exact roll count depends on thickness and roll width; we calculate by the liner weight per m² and container weight limit.

The recommended minimum order is 5000 m². Since geomembrane is bulky and heavy, we suggest at least one 20GP container for efficient shipping. We can also assist in consolidating with other cargo if needed.

We are a China geomembrane manufacturer, and shipments can be arranged from any major Chinese port such as Qingdao, Shanghai, or Ningbo.

Ready to Specify a Geomembrane?

- 15+ Years of Factory-Direct Expertise

- Custom-Engineered Solutions for Your Needs

- Global Shipping & Logistics Support

- A Transparent, No-Obligation Quote

- 100% Confdentiality Guaranteed

Your email information will be kept strictly confdential and our business staff will ensurethat your private information is absolutely safe!

Contact

- info@waterproofspecialist.com

Reply within 12 hours!

Please pay attention to the email with the suffix “@waterproofspecialist.com”.