New gravel driveway looks great for a few month, but then the ruts appear. After a heavy rain, potholes form, gravel washes away, and you're left with a muddy mess.

To select the right geocell, match the cell height to your heaviest vehicle load. For residential driveways with cars, 5-7.5 cm height is best. For areas with trucks, use 10-15 cm. Also, ensure the sheet thickness is at least 1.0-1.5mm and the cell opening accommodates your gravel infill.

I've exported countless containers of geocells for projects all over the world. The biggest and most expensive problem I see isn't the product failing; it's the wrong product being chosen for the job. A geocell that works for a garden path will absolutely fail under a delivery truck. Let's break down how to pick the perfect geocell for your specific driveway so you only have to build it once.

What driveway conditions require geocell reinforcement?

You have a problem spot on your property—a sloped entrance, soft ground, or an area that turns to mud every spring. You're tired of dumping more and more gravel into a losing battle.

Geocell reinforcement is essential for driveways on soft clay or sandy soils, on any kind of slope, or in areas with poor drainage and heavy rainfall. The geocell structure confines the soil and gravel, preventing it from sinking, eroding, or washing away.

From my experience, geocells are not just a product; they are a problem-solver for bad ground conditions. They work by creating a stable foundation where one doesn't exist.

Soft or Muddy Ground

If your driveway is on soft soil like clay or silt, the weight of a vehicle pushes the gravel down into the mud. The geocell acts like a snowshoe, creating a semi-rigid slab that spreads the load over a much wider area. The tire pressure is no longer concentrated on a small patch of ground, so the gravel stays on top instead of disappearing into the mud.

Sloped Driveways

Gravity and rainwater are the enemies of a sloped gravel driveway. They constantly pull the gravel downhill. A geocell grid acts like thousands of small, interconnected retaining walls. Each cell holds its pocket of gravel firmly in place, resisting the forces of erosion and keeping your driveway surface stable and intact.

Heavy Rain and Poor Drainage

In areas with heavy rain, water flow can easily wash away loose gravel, creating channels and ruts. Geocell reinforcement creates a surface that is both stable and permeable. Water can drain vertically through the gravel infill without dislodging it, preventing erosion and keeping the driveway usable even in wet weather.

Which geocell height and thickness are suitable for driveways?

You're looking at different geocell options online and see heights of 5cm, 10cm, 15cm, and various material thicknesses. You feel like you're guessing, and a wrong guess could be costly.

For a typical residential driveway, a geocell height of 5cm or 7.5cm is perfect for handling cars and SUVs. A sheet thickness of 1.0mm to 1.5mm offers the right balance of strength and cost-effectiveness for this type of application.

Choosing the right dimensions is a balance between performance and cost. You don't want to under-engineer the solution, but there's no need to pay for overkill.

Geocell Height: The Most Important Factor

| The height of the geocell determines the depth of the confined, reinforced layer. Think of it as the thickness of a concrete slab. A taller geocell creates a thicker, stronger "beam" that is much better at distributing heavy loads. My general recommendation for clients is based on the vehicle type: | Primjena | Recommended Height | Vehicle Type |

|---|---|---|---|

| Light Duty | 5 - 7.5 cm (2-3 in) | Passenger cars, SUVs | |

| Medium Duty | 7.5 - 10 cm (3-4 in) | Light trucks, RVs | |

| Heavy Duty | 10 - 20 cm (4-8 in) | Delivery trucks |

Material Thickness

Sheet thickness relates to the durability and puncture resistance of the cell walls. For most driveways using standard gravel infill, a 1.0mm or 1.5mm thickness is perfectly adequate. If you are building a heavy-duty industrial access road and using large, sharp angular rock as infill, you might consider a thicker 1.8mm sheet for extra abrasion resistance during compaction. For 99% of driveway projects I've supplied, 1.5mm is the safe, reliable choice.

How does expected vehicle load influence geocell selection?

You're building the driveway for your family car, but what about the occasional heavy visitor? A concrete delivery truck for a backyard project, a large moving van, or an emergency vehicle like a fire truck.

Always select the geocell height based on the heaviest vehicle that could ever use the driveway. A light car's load can be handled by a 5cm cell, but a single pass from a heavy truck will cause that system to fail. A 10-15cm cell provides a much higher safety factor.

The physics here is simple. It's all about pressure. A heavy truck concentrates immense weight onto a few small tire contact patches. The geocell's job is to take that concentrated pressure and spread it out so the weak soil underneath can handle it. A taller geocell does this far more effectively. Imagine the load distributing downwards in a cone shape. A taller geocell creates a much wider cone, reducing the pressure on the subgrade. I always tell my clients that spending a little extra on a taller geocell is the cheapest insurance you can buy for your driveway.

| Vehicle Type | Recommended Geocell Height | Obrazloženje |

|---|---|---|

| Passenger Car (Sedan, SUV) | 5 - 7.5 cm (2-3 inches) | Distributes light axle loads effectively on firm ground. |

| Light Truck, Camper, Boat Trailer | 7.5 - 10 cm (3-4 inches) | Handles moderate loads and prevents long-term rutting. |

| Heavy Truck (Moving, Concrete, Septic) | 10 - 15 cm (4-6 inches) | Necessary to prevent subgrade failure from high point loads. |

| Fire Truck / Emergency Access Lane | 15 - 20 cm (6-8 inches) | Ensures a stable, reliable surface under extreme loads. |

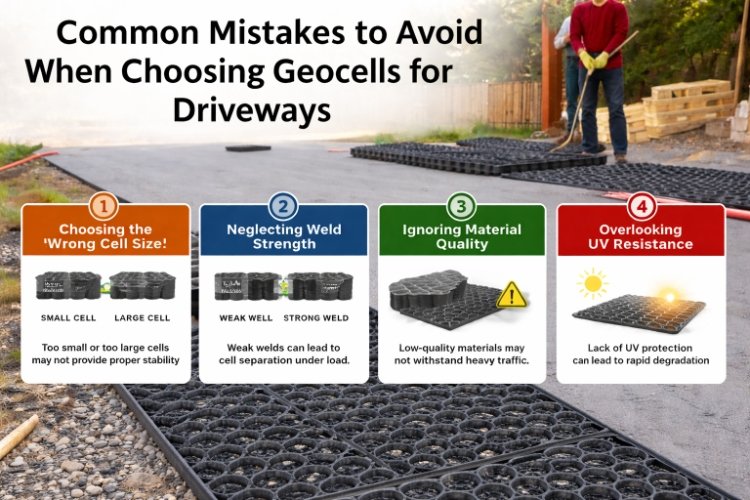

What common mistakes should be avoided when choosing geocells for driveways?

You have the height and thickness figured out. But there are other specifications like cell size and weld strength that you see on product data sheets. Ignoring these can lead to a failed installation.

The biggest mistakes are choosing a cell size that's wrong for your gravel, ignoring the weld strength of the seams, and under-specifying the height to save money. These errors can cause the system to fail during installation or under its first heavy load.

A perfect driveway project depends on getting these final details right. As a supplier, I make sure my clients understand these points before they place an order.

-

Mismatching Cell Size and Infill: Your gravel particles should be smaller than the cell opening, but not so small that the confinement effect is lost. A simple rule I provide is that the largest stone in your gravel mix should be no more than 1/3 of the geocell height. For most driveways, a medium-sized cell (often specified with a 356mm weld distance) is the perfect all-rounder for common gravel aggregates.

-

Ignoring Weld Strength: The ultrasonic welds are what hold the entire geocell panel together. Weak welds can pop open when you stretch the panel out or fill it with heavy stone. This is a sign of a low-quality manufacturer. I always tell my customers to look at the "seam peel strength" on the data sheet. For a load-bearing application like a driveway, it should be at least 100 N/cm.

-

Choosing Height Based on Budget, Not Load: This is the most common and most costly mistake. A customer tries to save a few hundred dollars by buying a 5cm geocell for a driveway that will see delivery trucks. The system fails within a year, and the cost to tear it out and replace it is ten times the initial "savings." Always, always choose the height based on the heaviest expected load.

Zaključak

Selecting the right geocell means matching its height to your heaviest vehicle load and its cell size to your chosen gravel. Getting these simple specifications right ensures a stable, maintenance-free driveway that lasts.