You're sourcing a geomembrane for a containment project. The choice between a smooth or a textured surface seems like a minor detail, but making the wrong decision can lead to catastrophic, multi-million dollar failures.

The primary difference is friction. Smooth geomembranes have a flat, low-friction surface for flat areas, while textured geomembranes have a rough, high-friction surface designed to prevent sliding and ensure stability on steep slopes.

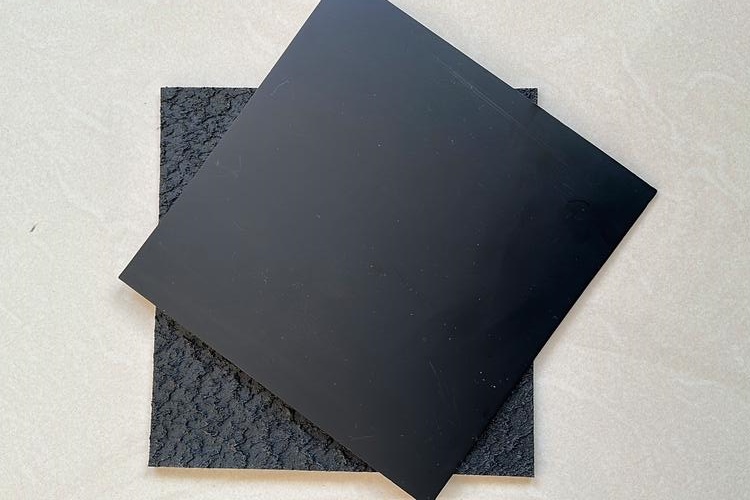

As a geosynthetics supplier, I often see this choice cause confusion for importers and project managers. They see two black liners, but they don't see the critical engineering difference that dictates where each one can be safely used. A smooth liner used on a steep slope is like putting a skating rink under your soil cover—it's not a matter of if it will fail, but when. Let’s break down exactly how these two products differ in structure, performance, application, and cost so you can make the right choice every time.

What are textured and smooth geomembranes made of and how are they produced?

You're looking at two HDPE liners, and they seem identical apart from the surface finish. It's easy to assume they are the same product, but their internal structure and manufacturing process are fundamentally different.

A smooth geomembrane is a single, uniform sheet of polymer produced through simple extrusion. A textured geomembrane is a composite product where a rough surface layer is co-extruded onto a smooth core, creating an integrated, patterned surface.

A Tale of Two Structures

While both liners typically start with the same high-quality HDPE resin, the journey from raw material to finished product creates two distinct materials. As someone who works with the factories, I can tell you the production line for a textured liner is more complex.

A smooth geomembrane is straightforward—molten resin is pushed through a die to form a flat, consistent sheet. That's it. It’s a uniform, or homogeneous, material from top to bottom.

A textured geomembrane, however, requires an extra step. During the co-extrusion process, a texturing agent (like nitrogen gas in the blow-film method) or a patterned roller is used to create the rough surface. This means the final product has a smooth base core with a textured layer bonded to it. This structural difference is key.

| Siffar | Smooth Geomembrane | Textured Geomembrane |

|---|---|---|

| Tsarin | Homogeneous, single layer | Composite (smooth core + textured layer) |

| Appearance | Shiny, reflective, flat | Matte, rough, patterned |

| Feel | Slippery to the touch | Grippy, coarse |

| Manufacturing | Simple extrusion | Co-extrusion with texturing step |

| Thickness | Uniform and consistent | Core thickness + texture height |

How does surface texture affect friction, slope stability, and installation performance?

You know texture adds "grip," but how much of a difference does it really make? Underestimating this can lead you to approve a design that is fundamentally unstable and at risk of a liner slide.

Surface texture is the single most important factor for slope stability. A textured surface can more than double the interface friction, creating the mechanical grip needed to lock the liner in place and prevent catastrophic failure on slopes.

The Physics of Grip

The difference in performance is not subtle; it's a dramatic engineering shift. The core function of a geomembrane—to be an impermeable barrier—is identical in both products. Their ability to stay put on a hill, however, is worlds apart.

-

Friction Coefficient: The Critical Number

In engineering terms, grip is measured by the friction coefficient. A smooth geomembrane against soil or a geotextile has a very low friction coefficient, typically around 0.2 to 0.3. This is dangerously slippery. The rough bumps on a textured geomembrane mechanically interlock with the adjacent material, boosting the friction coefficient to 0.4 to 0.6 or higher. This massive increase in frictional resistance is what holds the entire system together. -

Installation and Welding

This performance difference extends to installation. On a flat surface, welding a smooth liner is easy. On a slope, however, smooth liners are difficult to handle and require extensive anchoring with sandbags to stop them from sliding down before they are even welded. Textured liners are much easier to walk on and position on slopes. However, welding them requires more skill. The welder must be careful to avoid welding over a large texture point, which can create a channel or void in the seam and compromise its integrity.

In what types of projects should I choose textured versus smooth geomembranes?

You need a liner for a project with both a flat bottom and steep sides, like a reservoir. It's tempting to use one type for the whole job to simplify purchasing, but this is a costly mistake.

Use smooth geomembranes for flat or gently sloped areas (slope < 1:3) like pond bottoms. For any steep slope (slope ≥ 1:3) or where sliding is a risk, you must use a textured geomembrane for safety and stability.

The Golden Rule: Let the Slope Decide

This is the simplest and most important rule in liner selection. As a supplier, this is the first question I ask a client: "What is the slope of the area you are lining?" The answer immediately determines which product is appropriate. Trying to save money by using a cheaper smooth liner on a steep slope is the number one cause of liner system failures.

Here is a simple guide for your projects:

Choose SMOOTH Geomembranes for:

- Landfill Bottom Liners

- Reservoir, Pond, and Lake Bottoms

- Irrigation Canals (on flat or very gentle grades)

- Secondary Containment for Storage Tanks

- Basement and Foundation Waterproofing

Choose TEXTURED Geomembranes for:

- Landfill Side Slopes and Caps

- Mining Heap Leach Pad Slopes

- Dam and Embankment Linings

- Steeply Sloped Canals

- Any application where a soil or geosynthetic layer will be placed on top of the liner on a slope.

If your project has both flat and steep areas, it is standard practice to use smooth liner on the bottom and transition to textured liner for the side slopes.

How do their thickness, cost, and durability compare in real applications?

You're comparing quotes, and the textured liner is 20% more expensive than the smooth one with the same 1.5mm thickness. Is it worth the extra cost, and how does that affect the product's durability?

Textured geomembranes cost 10% to 30% more than smooth ones due to the complex manufacturing process. While both are highly durable, the textured liner's higher upfront cost provides essential insurance against slope failure, making it the better long-term value.

A Value-Based Comparison

Focusing only on the price per square meter is a common trap for importers. The true measure is the total installed cost and the long-term security of the project.

-

Cost Breakdown

The price difference is directly tied to production. The extra step of adding texture makes the product more expensive. Compared to a smooth liner of the same core thickness:- Single-sided textured liner: Costs about 10-15% more.

- Double-sided textured liner: Costs about 20-30% more.

While this seems significant on a purchase order, it is tiny compared to the cost of re-excavating and rebuilding a failed slope.

-

Durability and Mechanical Properties

Both liner types are made from durable HDPE and are designed to last for decades when buried. From a purely technical standpoint, a smooth liner has slightly higher tensile strength and elongation because it is a single, uniform material. A textured liner is a composite, and its strength relies on the bond between the core and the textured layer. However, in the real world, this small difference is irrelevant. The functional durability of a textured liner on a slope is infinitely greater because it is designed to handle the specific stresses of that environment.

Ƙarshe

The choice is simple when you focus on the C-word. The fundamental difference between smooth and textured geomembranes is friction, which directly dictates their application. Use smooth for flat surfaces to save costs, and always specify textured for slopes to ensure project safety and long-term stability.