Choosing the wrong geosynthetic can lead to catastrophic failure. Using a permeable fabric where you need a barrier causes leaks, while using a barrier where you need drainage causes pressure buildup.

A geomembrane is an impermeable plastic barrier designed to stop water and fluid migration completely. A geotextile is a permeable fabric used for filtration, separation, drainage, and reinforcement. In short, one is a liner to contain water, the other is a fabric to manage it.

While both are essential materials in civil and environmental engineering, their functions are fundamentally opposite. Using one in place of the other is not a minor substitution; it's a critical design error that can compromise the safety and longevity of your entire project. Let's break down where each belongs.

What are the basic differences between geomembrane and geotextile materials?

On a construction site, both materials arrive in large rolls. This can lead to confusion and incorrect specification, a costly mistake that undermines the engineering design before the project even begins.

A geomembrane is a solid, non-porous polymer sheet, like a heavy-duty plastic liner. A geotextile is a porous, fibrous fabric, either woven or non-woven. The key difference is that one is designed to be a barrier, while the other is designed to be a filter.

This fundamental difference in material structure dictates everything from installation method to end-use application. One creates an impenetrable wall against fluids, while the other works with soil and water to improve ground conditions.

Material at a Glance

| Característica | Geomembrana | Geotextil |

|---|---|---|

| Purpose | Barrier. To block/contain fluids and gas. | Fabric. To filter, separate, reinforce, or drain. |

| Material | Polymers (HDPE, LLDPE, PVC) | Synthetic Fibers (Polypropylene, Polyester) |

| State | Impermeable (waterproof) | Permeable (allows water to pass) |

| Seams | Requires professional thermal welding for integrity. | Joined by simple overlapping or sewing. |

How do their functions differ in seepage control, filtration, and reinforcement?

Your project might require both water containment and soil stability. Using a single material for both jobs is often impossible and will lead to failure in one or both functions, wasting time and money.

Geomembranes provide seepage control by acting as an impermeable barrier. Geotextiles offer filtration by letting water pass while holding back soil, and reinforcement by adding tensile strength to soil structures. One contains, the other manages and strengthens.

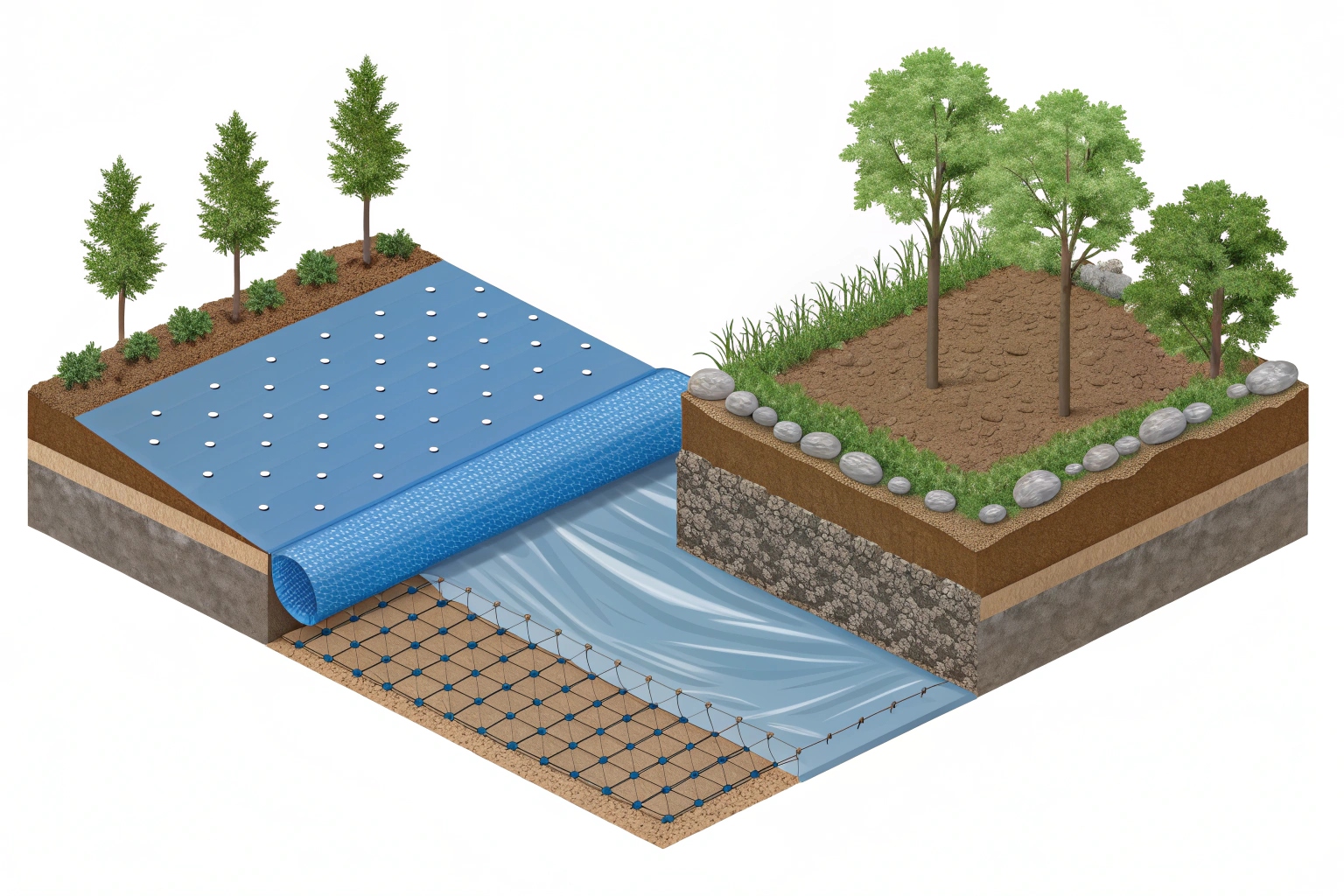

Their functions are not interchangeable; they are distinct and often used together in a system where each performs its specialized role.

Functional Breakdown

- Seepage Control: This is the exclusive job of a geomembrane. Its extremely low permeability creates a watertight liner for ponds, landfills, and canals, ensuring total containment.

- Filtration and Drainage: This is a primary function of a geotextile. It allows groundwater to pass into a drainage system without letting fine soil particles wash away and cause clogging.

- Reinforcement: Woven geotextiles add significant tensile strength to soil, similar to how rebar works in concrete. They are used to stabilize steep slopes, embankments, and road bases.

- Protection: In many systems, a thick, non-woven geotextile is placed above and/or below a geomembrane to act as a protective cushion, preventing punctures from sharp rocks or subgrade irregularities.

When should I use geomembrane instead of geotextile in an engineering project?

Choosing the wrong material is a high-stakes gamble. A geotextile used for a pond liner will leak immediately. A geomembrane used for sub-road drainage will trap water and destabilize the structure.

Use a geomembrane whenever the primary objective is containment—stopping fluids from escaping. Use a geotextile when you need to manage soil and water interaction through filtration, separation, or reinforcement. If you need both functions, they are used together.

The decision process should be simple and function-driven. If the goal is to keep liquid in or out, the answer is always geomembrane. For anything else related to soil mechanics, start with a geotextile.

Application Guide

| Use a Geomembrane for... | Use a Geotextile for... | Use Both Together for... |

|---|---|---|

| Pond, Reservoir, & Canal Liners | Separation & Stabilization Under Roads | Landfill Lining Systems (Geotextile protects geomembrane) |

| Landfill Base Liners & Caps | Drainage Behind Retaining Walls | Lined Ponds & Canals (Cushioning layer) |

| Wastewater Treatment Lagoons | Erosion Control on Slopes & Shorelines | Critical Containment with Puncture Risk |

| Secondary Containment Systems | Reinforcement of Embankments & Soft Soil | Composite Drainage Systems |

How can I select the right geosynthetic material for long-term performance and cost efficiency?

You need a reliable solution, not just the cheapest roll. Specifying based on price alone without matching performance to the project's demands is a recipe for costly long-term problems.

First, clearly define the primary function: containment (geomembrane) or soil management (geotextile). Then, review the product's Technical Data Sheet (TDS) to ensure its properties (e.g., thickness, strength, permeability) meet your project's specific engineering requirements.

A smart selection process is data-driven and ensures you get the performance you pay for without over-engineering. Your choice should be a balance between project demands, material properties, and budget.

A Simple Selection Process

- Identify the Primary Goal: Is your main objective to block water flow (containment) or to manage soil interaction (filter, separate, reinforce)? Your answer immediately points you to either geomembrane or geotextile.

- Define Performance Needs: If containment is needed, what level of chemical resistance and durability is required? This will guide your choice of geomembrane type (e.g., HDPE) and thickness.

- Evaluate Site Conditions: If you need soil management, what are the loads (for reinforcement) or soil types (for filtration)? This will determine if you need a woven or non-woven geotextile and its specific grade.

- Consider a System Approach: For critical projects, a composite system using both materials often provides the most robust and cost-effective long-term solution. The geotextile protects the more expensive geomembrane, extending the life of the entire system.

Conclusión

The choice is simple: geomembranes are barriers that stop water, while geotextiles are fabrics that manage it. Selecting the correct one is the first step to a successful, durable, and cost-effective project.