Geomalla de fibra de vidrio: alta resistencia a la tracción & Resistencia al agrietamiento para refuerzo de asfalto

Malla duradera de fibra de vidrio para refuerzo de pavimentos asfálticos, prevención de grietas y rehabilitación de carreteras: suministro directo de fábrica

Exportar Globalmente

Directamente de fábrica

Calidad certificada

Propiedades clave de Geomalla de fibra de vidrio

Proporciona un refuerzo fuerte en ambas direcciones, normalmente de 25 a 200 kN/m.

Mantiene la forma y la estabilidad bajo cargas pesadas con ≤ 3–4 % de alargamiento.

Previene grietas reflectantes, térmicas y de fatiga en capas asfálticas.

Funciona de manera confiable desde −260 °C hasta +650 °C durante la pavimentación con asfalto y en climas fríos.

El recubrimiento de polímero o betún mejora la adhesión con los materiales del pavimento.

Resiste la corrosión ácida, alcalina y de agua salada para una larga vida útil.

Mantiene la integridad mecánica bajo la luz solar y la fuerte exposición al aire libre.

Reduce la frecuencia de mantenimiento distribuyendo tensiones y evitando deformaciones.

Llegar a saber Geomalla de fibra de vidrio

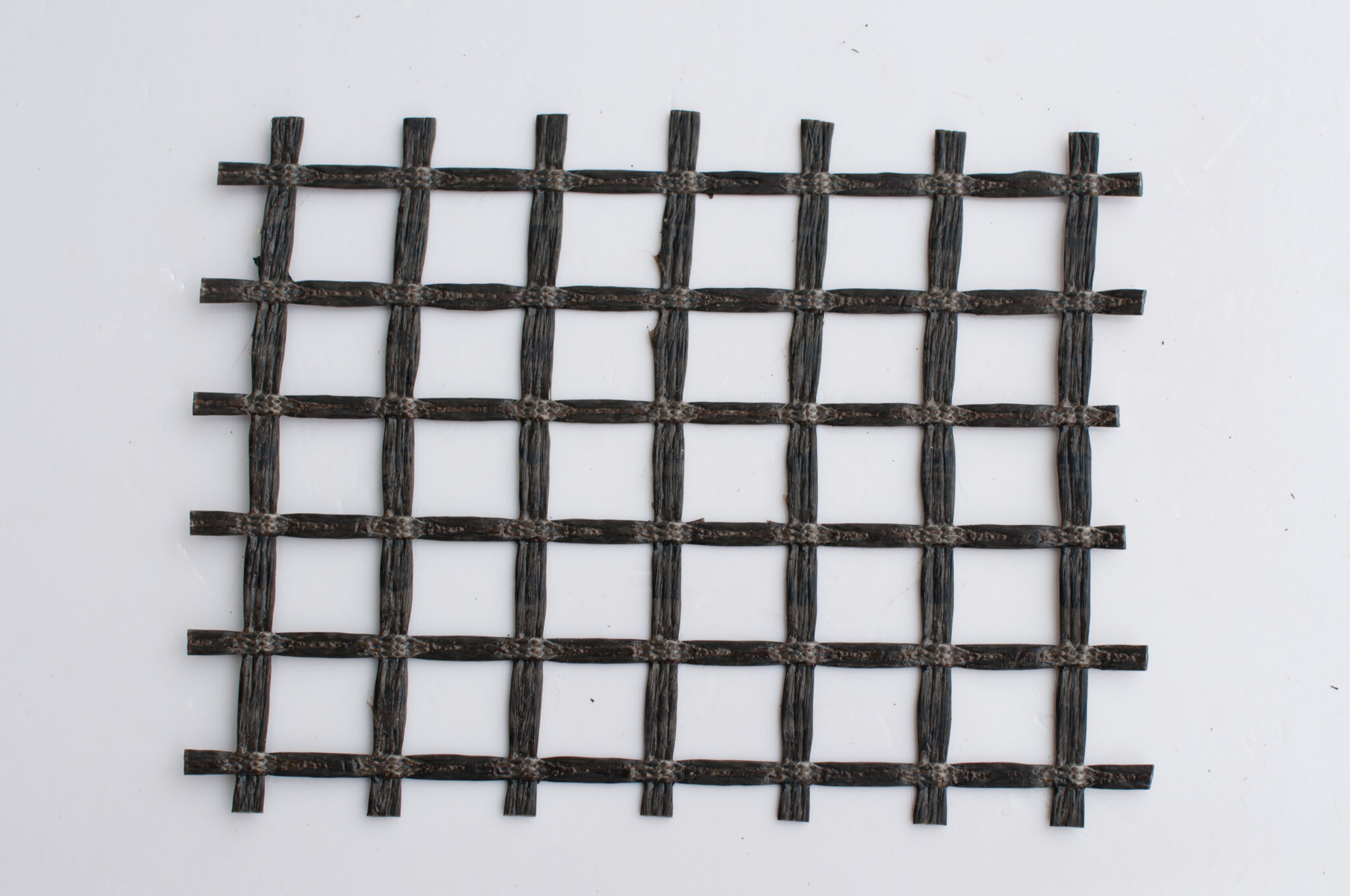

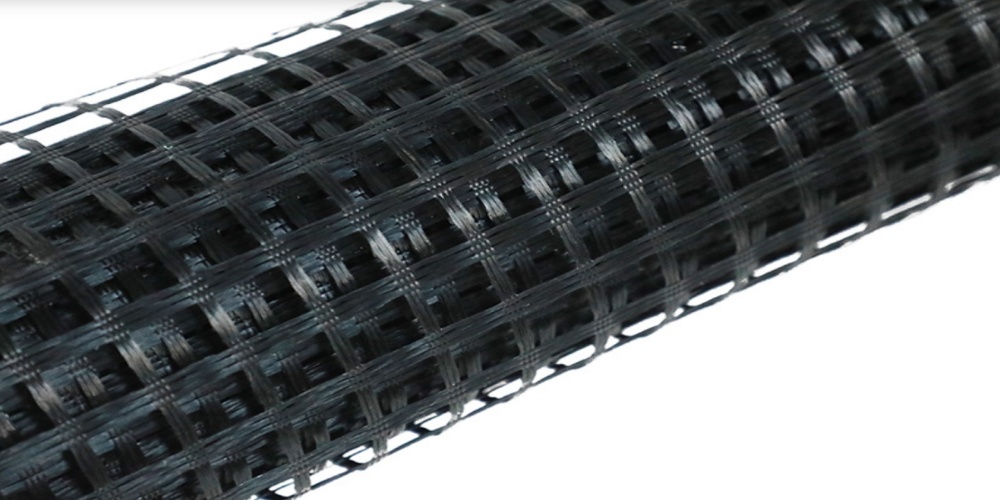

Una geomalla de fibra de vidrio es una malla geosintética de alta resistencia hecha de fibras de vidrio libres de álcalis recubiertas con betún o resina polimérica. Refuerza el pavimento asfáltico y evita fisuras reflectantes.

Se utiliza ampliamente en el refuerzo de pavimentos asfálticos, rehabilitación de carreteras antiguas, pistas de aeropuertos, cubiertas de puentes y protección de pendientes para prolongar la vida útil del pavimento y reducir los costos de mantenimiento.

Al distribuir la tensión de tracción de manera uniforme y reducir la tensión en las capas de asfalto, previene el agrietamiento térmico y reflectante bajo tráfico intenso o fluctuaciones de temperatura.

La geomalla de fibra de vidrio ofrece un módulo de tracción más alto y una mejor resistencia al calor, mientras que la geomalla de poliéster proporciona una mayor flexibilidad y un mejor rendimiento en el refuerzo de suelos blandos.

Sí. Mantiene la integridad estructural a temperaturas de mezcla y pavimentación de asfalto superiores 190 ºC.

Tipos y opciones de materiales de Geomalla de fibra de vidrio

Geomalla de fibra de vidrio (refuerzo de fibra de vidrio)

Descripción:

La geomalla de fibra de vidrio está hecha de hilos de fibra de vidrio sin álcalis tejidos en una estructura de malla estable y recubiertos con betún o resina polimérica.

Esta disponible en dos tipos: autoadhesivos y no adhesivos.

El tipo autoadhesivo simplifica la instalación y mejora la unión con superficies asfálticas, mientras que el tipo no adhesivo proporciona una mayor flexibilidad para pavimentación a alta temperatura.

La geomalla de fibra de vidrio ofrece alta resistencia a la tracción, bajo alargamiento, y excelente resistencia al agrietamiento, lo que lo convierte en el refuerzo preferido para pavimentos asfálticos, tableros de puentes y rehabilitación de carreteras.

Propiedades clave:

Alta resistencia a la tracción (25–200 kN/m) con ≤ 3 % de alargamiento

Fuerte unión con capas de asfalto mediante revestimiento bituminoso.

Resistencia superior al calor y a la corrosión

Excelente resistencia a la fatiga y al agrietamiento bajo carga de tráfico.

Ligero, flexible y fácil de instalar

Funciones & Aplicaciones:

Refuerzo de pavimento asfáltico antiguo para evitar fisuras reflectantes

Refuerzo de superposiciones de pavimentos de cemento y capas de base de carreteras.

Protección para tableros de puentes y pistas de aeropuertos

Utilizado en protección de taludes, estabilización de terraplenes y refuerzo de suelos blandos.

Adecuado para proyectos de pavimentación en climas fríos y cálidos.

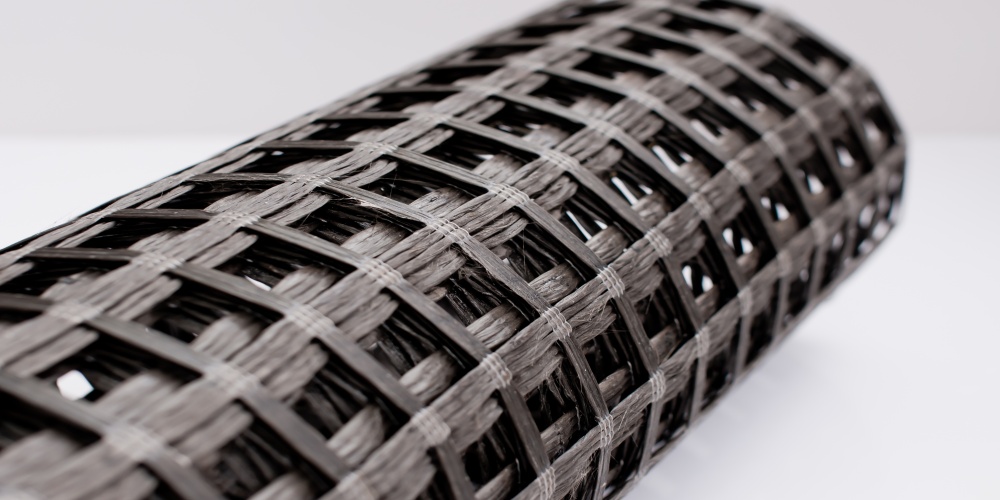

Geomalla de basalto (refuerzo de fibra de basalto)

Descripción:

La geomalla de basalto se produce a partir de fibras continuas de basalto tejidas en una malla de alta resistencia y recubiertas con betún o resina epoxi.

Cuenta con estabilidad térmica excepcional, resistencia química, y rendimiento ecológico, funcionando eficazmente desde −260 °C hasta +650 °C.

El material proporciona un módulo alto, un alargamiento bajo (≤ 4 %) y una excelente adherencia con asfalto u hormigón.

La geomalla de basalto se usa ampliamente para prevención de grietas, refuerzo de cemento, y protección de carreteras y puentes, superando a la fibra de vidrio tradicional en ambientes extremos.

Propiedades clave:

Alta resistencia a la tracción (40–160 kN/m) con ≤ 4 % de alargamiento

Excelente resistencia a ácidos, álcalis y sales.

Fuerte estabilidad térmica de −260 °C a 650 °C

Respetuoso con el medio ambiente y no corrosivo

Control superior de grietas y ahuellamientos bajo cargas repetidas

Funciones & Aplicaciones:

Refuerzo de carreteras asfálticas y prevención de grietas por superposición

Capas impermeabilizantes y antifisuras para tableros de puentes

Refuerzo de paredes de cemento y hormigón (por ejemplo, paneles de GRC, tableros de EPS)

Revestimiento de túneles, presas y protección de taludes

Estabilización de pavimentos de carreteras, ferrocarriles y puertos.

Especificaciones técnicas de Geomalla de fibra de vidrio (autoadhesiva versus no adhesiva)

| Modelo | Resistencia a la tracción (kN/m) | Elongación de rotura (%) | Tamaño de malla (mm×mm) |

|---|---|---|---|

| GGA25 | ≥25 | ≤3 | 25×25 |

| GGA30 | ≥30 | ≤3 | 25×25 |

| GGA40 | ≥40 | ≤3 | 25×25 |

| GGA50 | ≥50 | ≤3 | 25×25 |

| GGA80 | ≥80 | ≤3 | 25×25 |

| GGA100 | ≥100 | ≤3 | 25×25 |

| GGA120 | ≥120 | ≤3 | 25×25 |

| Modelo | Resistencia a la tracción (kN/m) | Elongación de rotura (%) | Tamaño de malla (mm×mm) |

|---|---|---|---|

| GG25 | ≥25 | ≤3 | 25×25 |

| GG30 | ≥30 | ≤3 | 25×25 |

| GG40 | ≥40 | ≤3 | 25×25 |

| GG50 | ≥50 | ≤3 | 25×25 |

| GG80 | ≥80 | ≤3 | 25×25 |

| GG100 | ≥100 | ≤3 | 25×25 |

| GG120 | ≥120 | ≤3 | 25×25 |

Geomalla de fibra de vidrio Guía de instalación

Guía de instalación de geomalla de fibra de vidrio

Las geomallas de fibra de vidrio están disponibles en dos tipos principales: autoadhesivo y no adhesivo.

Las rejillas autoadhesivas se pueden colocar directamente sobre la superficie de la base preparada, mientras que las rejillas no adhesivas normalmente se fijan con clavos o tiras de acero.

Método de instalación de geomalla de fibra de vidrio no adhesiva

Método de fijación de uñas

Al colocar una geomalla de fibra de vidrio no adhesiva, primero rocíe una capa adhesiva sobre la capa existente.

Fije un extremo de la geomalla con una tira de acero y clavos. Los clavos se pueden clavar con un martillo o una pistola de clavos.

Luego tira de la geomalla. apretado y recto, fijándolo en secciones de 2 a 5 metros cada.

Para pavimentos de hormigón de cemento, los segmentos pueden seguir el espaciamiento de las juntas de contracción. Los clavos deben colocarse a lo largo de las juntas, asegurándose de que tanto la dirección longitudinal como la transversal permanezcan tensas.Longitud de superposición

La superposición longitudinal debe ser ≥ 20 cm, y la superposición transversal debe ser ≥ 15 cm.

La hoja delantera debe superponerse a la trasera en la dirección de extendido.Requisitos de fijación

No martille directamente sobre la rejilla de fibra de vidrio ni clave clavos a través de los hilos de la rejilla.

Si los clavos se rompen o la tira de acero se afloja, vuelva a fijarla inmediatamente.Rodamiento y estabilización

Después de la instalación, compacte la rejilla usando un rodillo con ruedas de goma para asegurar una adhesión firme a la base.

Controle estrictamente el tráfico de construcción: los vehículos no deben hacer giros bruscos, frenar repentinamente ni arrojar la mezcla asfáltica directamente sobre la rejilla expuesta para evitar daños.

2. Método de instalación de geomalla de fibra de vidrio autoadhesiva

Trabajo de preparación

Complete todo el sellado de grietas, parcheo de baches, refuerzo de la base y nivelación antes de la instalación.Condición de la superficie

La superficie de la carretera debe ser limpio, seco y libre de polvo, con una temperatura entre 5°C y 60°C.Almacenamiento de productos

Guarde la geomalla autoadhesiva en un ambiente seco y ventilado para mantener el rendimiento adhesivo.Precauciones

Los trabajadores deberán utilizar guantes al manipular la rejilla autoadhesiva.

Evite las marcas viales u obstáculos cuando sea necesario.

Durante la colocación, aplicar tensión suficiente para prevenir las arrugas.

Longitudes de superposición: longitudinal = 75–150 mm; transversal = 25–50 mm, con solapamientos siguiendo la dirección de extendido.

Después de rodar, sólo se permite el paso a vehículos de construcción o de emergencia; Evite girar o frenar para evitar daños.

La capa asfáltica debe colocarse el mismo dia como la instalación de la red, con un espesor mínimo de capa asfáltica de ≥ 40 milímetros.

Métodos de colocación

(1) Tendido mecánico:

Monte el rollo en un marco desenrollador montado en la parte delantera de un tractor, con el lado adhesivo hacia abajo.

Avance lentamente para asegurarse de que la rejilla esté plana y alineada. Compacto con un rodillo con neumáticos de goma (1 o 2 pasadas), luego aplicar la mezcla asfáltica.

¿Por qué elegir? ¿Especialista en WP?

A lo largo de los años, Especialista en WordPress se ha ganado una sólida reputación como uno de los proveedores de confianza de China. fabricantes de geomallas y proveedores globales de materiales geosintéticos.

Nos enfocamos en entregar material de geomalla confiable que satisfacen las exigentes necesidades de Proyectos de ingeniería civil, vial e hidráulica. mundial.

Nuestra geomalla combina alta resistencia a la tracción, estabilidad y calidad constante, respaldada por experiencia técnica y servicio directo de fábrica.

- Muestras gratuitas de tela de geomalla de fibra de vidrio

- Soporte experto en proyectos

- Garantía de calidad confiable

- Más de 10 años de experiencia en fabricación

- Suministro directo de fábrica

¿Listo para especificar una geomalla?

- Más de 15 años de experiencia directa de fábrica

- Soluciones de ingeniería personalizada para sus necesidades

- Envío global & Soporte logístico

- Una cita transparente y sin compromiso

- 100% Confdencialidad garantizada

Su información de correo electrónico se mantendrá estrictamente confidencial y nuestro personal comercial se asegurará de que su información privada esté absolutamente segura.

Contacto

- info@waterprowpecialist.com

Responder dentro de las 12 horas!

Preste atención al correo electrónico con el sufijo "@Waterproofpecialist.com".