Accurately calculating the material quantities for a new landfill cell is one of the most critical steps in project planning. It forms the basis of your budget, procurement schedule, and construction timeline. Underestimating can lead to costly delays and emergency orders, while significant overestimation ties up capital and creates logistical headaches. This is not just about simple area and volume calculations; it's about understanding how each layer interacts and accounting for the realities of construction—overlaps, waste, and site geometry.

As a geosynthetics supplier for global infrastructure projects, we've helped countless contractors and engineers build their Bill of Quantities (BOQ). This guide provides a detailed, step-by-step methodology for calculating the materials needed for a modern landfill cell. We'll start with the foundational geometric model and work our way up through each layer, from the subgrade to the protective cover, providing practical formulas and waste factors along the way.

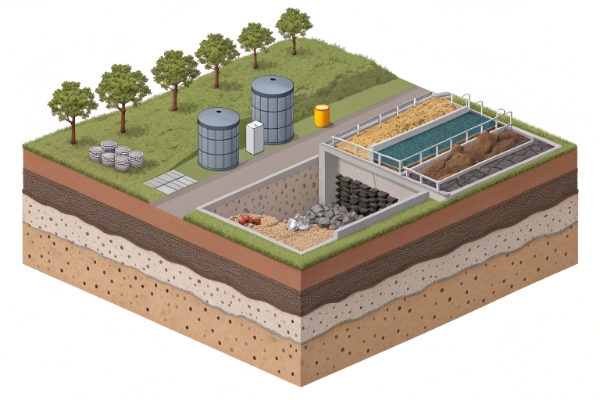

Before a single calculation is made, you must have a clear geometric model of the cell.

1. Understanding the Structure of a Landfill Cell

Every calculation begins with a clear geometric model. You need a set of engineering drawings that detail the cell's dimensions:

- Base Dimensions: The length and width of the cell floor.

- Depth: The vertical height from the cell floor to the top of the berms.

- Side Slopes: The gradient of the interior slopes, typically expressed as a ratio (e.g., 3H:1V, meaning 3 meters horizontal for every 1 meter vertical).

- Anchor Trenches: The dimensions and location of the trenches at the top of the slopes used to secure the geosynthetic materials.

With these dimensions, you can calculate the three fundamental surface areas that will be the basis for nearly all subsequent material calculations:

- Base Area:

Base Area = Cell Length × Cell Width - Total Slope Area: Calculate the area of each of the four side slopes and sum them. The length of a slope (hypotenuse) is calculated using the Pythagorean theorem:

Slope Length = √(Vertical Height² + Horizontal Run²). Then,Slope Area = Slope Length × Slope Width. - Anchor Trench Area: Calculate the "unfolded" surface area of the trench (bottom + two vertical sides) and multiply by its total length around the cell's perimeter.

The Total Liner Area is the sum of these three areas: Total Liner Area = Base Area + Total Slope Area + Anchor Trench Area. This total area is the foundational number for all geosynthetic materials.

2. Calculating Geomembrane Quantities

The geomembrane is the primary impermeable barrier. Both smooth geomembrane (for the base) and textured geomembrane (for the slopes, to increase friction) are often used in the same cell, so their quantities may need to be calculated separately.

Formula:

Required Geomembrane (m²) = Total Liner Area × (1 + [Waste Factor](https://waterproofspecialist.com/calculate-geomembrane-quantity/))

Key Considerations:

- Seam Overlap: Geomembrane panels must be overlapped for welding, typically by 10-15 cm. This overlap is a planned part of the installation and must be accounted for in the waste factor.

- Waste Factor: This accounts for seam overlaps, necessary trimming around pipes and sumps, cut-offs at the panel ends, and potential replacement of damaged sections. A good rule of thumb is:

- Base Area: 5-8% waste factor.

- Slope Area: 8-12% waste factor, as working on slopes can generate more off-cuts.

- Anchor Trench Extension: Ensure the

Total Liner Areacalculation includes the extra material needed to run down into and across the bottom of the anchor trench before being backfilled.

3. Calculating GCL or Compacted Clay Quantities

This layer provides the secondary barrier in a composite liner system. The calculation method depends entirely on whether you are using a Geosynthetic Clay Liner (GCL) or a Compacted Clay Liner (CCL).

Geosynthetic Clay Liner (GCL)

GCL is a manufactured product delivered in rolls. The calculation is area-based, very similar to the geomembrane.

Formula:

Required GCL (m²) = Total Liner Area × (1 + Waste Factor)

Key Considerations:

- Overlaps: GCL panels have specified overlaps (typically 15-30 cm) that are essential for creating a continuous barrier.

- Waste Factor: A waste factor of 5-10% is standard to account for overlaps, trimming, and any damaged material.

Compacted Clay Liner (CCL)

A CCL is a constructed soil layer, so its quantity is calculated by volume and then converted to tonnage.

Formulas:

Compacted Volume (m³) = Total Liner Area × CCL Design Thickness (e.g., 0.6 m)Required Loose Volume (m³) = Compacted Volume / Compaction Factor (e.g., 0.9)Required Tonnage (tonnes) = Loose Volume × Soil Density (e.g., 1.8 tonnes/m³)

Key Considerations:

- Compaction Factor: Soil is delivered and placed in a loose state and then compacted to meet a specified density. You will need more loose volume than the final, in-place compacted volume. This factor must be determined by geotechnical testing.

- Moisture Content: The density of the soil will vary with its moisture content, which can affect the required tonnage.

4. Calculating Geotextile Quantities (Protection & Separation Layers)

Nonwoven geotextiles are critical for protecting the geomembrane from puncture by overlying drainage stone or underlying subgrade. A geotextile may be placed both above and below the geomembrane.

The calculation method is identical to that for GCLs.

Formula:

Required Geotextile (m²) = Area to be Covered × (1 + Waste Factor)

Key Considerations:

- Location: Identify exactly where the geotextile is specified in the design. Is it only above the geomembrane? Is it also required below? Are different weights (e.g., 800 g/m² vs. 1200 g/m²) specified for the base versus the slopes?

- Waste Factor: Apply a 5-10% waste factor per area to account for seam overlaps and trimming.

5. Calculating Geonet and Geocomposite Drainage Quantities

The geonet or geocomposite forms the leachate collection and removal system (LCRS). As a geosynthetic roll good, its calculation is area-based.

Formula:

Required Drainage Composite (m²) = Area of LCRS × (1 + Waste Factor)

Key Considerations:

- Coverage Area: The drainage layer typically covers the entire base and slopes of the cell. Therefore, the

Area of LCRSis usually equal to theBase Area + Total Slope Area. It does not typically extend into the anchor trench. - Connections and Overlaps: Panels are often overlapped or connected with cable ties. Account for this in a standard waste factor of 5-10%.

6. Calculating Gravel or Sand Drainage Layer Requirements

If the design specifies a natural aggregate drainage layer (e.g., gravel or sand) instead of a geocomposite, the calculation is volume-based, similar to a CCL.

The calculation method follows the same principles outlined for a Compacted Clay Liner in Section 3, using the specific thickness and density of the gravel or sand.

7. Calculating Gas Collection Layer Materials (for MSW Cells)

For MSW cells, a gas collection layer may be installed above the waste as it is filled. The calculation for this layer's materials (if specified as gravel or a gas-venting geocomposite) follows the same volume or area logic as the leachate drainage layer.

For perforated pipes within this layer, refer to the pipe calculation method in the next section.

8. Calculating Pipe Quantities (Leachate & Gas Collection)

The network of perforated and solid pipes is the backbone of the leachate and gas collection systems.

Formula:

Total Pipe Length = Sum of all main headers, laterals, and cleanout risers based on the engineering layout.

Key Considerations:

- Layout Drawing: You MUST have a detailed layout drawing showing the location, diameter, and length of every pipe segment.

- Pipe Types: Create separate line items for different pipe types (e.g., perforated HDPE DN200 vs. solid HDPE DN300).

- Waste/Contingency: Add a waste factor of 3-5% to the total length for cuts. Additionally, budget for a contingency of 10-15% for fittings like tees, elbows, and couplers.

- Geotextile Sock: If pipes are to be wrapped in a filter geotextile, calculate its area:

Pipe Circumference × Total Pipe Length.

9. Calculating Protective Soil and Cover Soil Requirements

A layer of select soil or sand is often placed directly on top of the liner system to protect it from the initial placement of waste.

The calculation is a simple volume-to-tonnage conversion, following the same methodology as the Compacted Clay Liner in Section 3. Use the specified thickness and density for the protective soil layer. This same formula applies to daily and intermediate cover soil placed over the waste during operations.

10. Calculating Anchor Trench Quantities

The anchor trench calculation involves two parts: excavation and backfill.

Formula:

Excavation/Backfill Volume (m³) = Trench Cross-Sectional Area (m²) × Total Trench Length (m)

This informs the earthworks requirement. The quantity of geosynthetics needed to line the trench should have already been included in your Total Liner Area calculation in Step 1.

11. Final Quantity Checklist and Waste Factors

Waste factors are not arbitrary; they are an essential part of an accurate estimate. Here is a summary of typical recommended ranges:

| Material | Typical Waste Factor | Notes |

|---|---|---|

| Geomembrane (HDPE/LLDPE) | 5-12% | Higher for complex geometry and slopes. |

| GCL / Geotextiles | 5-10% | Accounts for overlaps and trimming. |

| Geocomposites / Geonets | 5-10% | Accounts for overlaps and connections. |

| Pipes & Fittings | 3-5% (length) + 10-15% (fittings) | Contingency for fittings is critical. |

| Gravel / Sand / Soil | 3-5% | Accounts for transport loss and compaction settlement. |

12. Summary: Building a Complete Bill of Quantities for a Landfill Cell

The final step is to organize all these calculations into a clear, comprehensive Bill of Quantities (BOQ). A simple spreadsheet is the perfect tool for this.

| Material Description | Unit of Measure | Required Quantity | Waste Factor | Total Order Quantity | Notes |

|---|---|---|---|---|---|

| Textured HDPE Geomembrane, 2.0 mm | m² | 12,500 | 10% | 13,750 | For side slopes (3H:1V) |

| Smooth HDPE Geomembrane, 2.0 mm | m² | 8,000 | 5% | 8,400 | For cell base |

| Geosynthetic Clay Liner (GCL) | m² | 20,500 | 8% | 22,140 | Covers base and slopes |

| Nonwoven Geotextile, 800 g/m² | m² | 20,500 | 8% | 22,140 | Protection layer over GCL |

| Geocomposite Drainage Layer | m² | 20,000 | 8% | 21,600 | Covers base and slopes, not anchor |

| Drainage Gravel, 20-40 mm | Tonnes | 3,840 | 4% | 3,994 | Based on 1.6 t/m³ density |

| Perforated HDPE Pipe, DN200 | Meters | 1,200 | 5% | 1,260 | Leachate collector laterals |

This organized BOQ becomes your master document for procurement, cost analysis, and project management. By following this structured, layer-by-layer approach and applying realistic waste factors, you can build a reliable material estimate that sets your landfill construction project up for success.