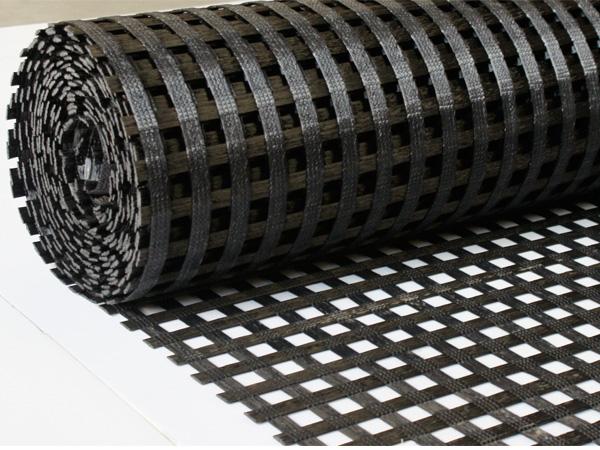

Polyester Geogrid— Factory-Direct Supplier for Soil Reinforcement Projects

Reinforce soil and stabilize foundations with warp-knitted polyester, steel-plastic, and fiber-plastic geogrids — engineered for slopes, retaining walls, and embankments. Factory-direct export with certified quality assurance.

تصدير العالمية

المصنع مباشرة

جودة معتمدة

Properties of البوليستر جيوغريد

Made from high-tenacity PET yarns and reinforced composites, polyester geogrids provide superior tensile strength and minimal elongation, ensuring stable soil reinforcement even under long-term load conditions.

Knitted polyester and steel-plastic structures maintain dimensional stability and resist long-term deformation, making them ideal for retaining walls, slopes, and soft foundation projects.

Available in warp-knitted polyester, steel-plastic, and fiber-plastic composite types to meet different project requirements — from heavy-duty retaining walls to flexible roadbed reinforcement.

Open grid apertures and coated surfaces promote strong interlocking with soil, gravel, and asphalt layers, preventing displacement and improving load distribution

Tensile strength available from 35 kN/m to 300 kN/m, with customizable width (up to 6 m), roll length, and coating type according to specific engineering design needs.

Get to Know البوليستر جيوغريد

A polyester geogrid is a soil reinforcement material made from high-tenacity PET yarns through warp-knitting and PVC coating. It offers high tensile strength and low elongation for long-term stability in civil engineering projects.

There are three main types: warp-knitted polyester geogrid, steel-plastic composite geogrid, and fiber-plastic composite geogrid. Each type serves different reinforcement needs depending on load and environmental conditions. structures.

They combine high strength, chemical resistance, and low creep with flexible installation. Compared to PP or HDPE grids, PET geogrids perform better in sustained loading and harsh environments.

Polyester geogrids are used for retaining walls, slopes, embankments, and soft soil foundations, where they improve soil stability and prevent deformation.

With proper installation and coating protection, polyester geogrids can last over 50 years, maintaining tensile performance and resisting UV, oxidation, and chemical corrosion.

Material Types of البوليستر جيوغريد

PET Geogrid

Description:

Warp-knitted polyester geogrid is made from high-tenacity PET yarns arranged in parallel and bonded by warp-knitting. The grid is usually coated with PVC or bitumen for durability and soil bonding. It offers high tensile strength, low elongation, and excellent creep resistance under long-term load.

Key Features:

High tensile strength with low elongation (≤10%)

Resistant to corrosion, aging, and UV radiation

Excellent soil interlocking and drainage compatibility

Lightweight, flexible, and easy to install

Applications:

Used for reinforcement of highways, railways, embankments, and retaining walls.

Also applied in slope protection, bridge abutment stabilization, and soft soil improvement projects.

Steel Plastic Geogrid

Description:

Steel-plastic composite geogrid consists of high-strength steel wires encapsulated in HDPE strips and welded into a grid structure. The steel core provides high load capacity, while the plastic coating protects against corrosion, oxidation, and chemical attack.

Key Features:

High strength and low creep, even under heavy loads

Steel-plastic bonding ensures long-term dimensional stability

Roughened surface improves friction with soil

Chemical and biological corrosion resistant, suitable for harsh environments

Applications:

Ideal for roadbed reinforcement, old pavement reconstruction, airport runways, landfill base stabilization, and slope protection.

Commonly used in high-load retaining walls and mining foundations.

Fiber Plastic Geogrid

Description:

Fiber-plastic geogrid is made from glass fiber, basalt fiber, or polyester fiber embedded in a polypropylene (PP) or polyethylene (PE) matrix. The grid is extruded and surface-textured for improved interlocking and chemical resistance. It offers a lightweight structure and high stiffness modulus.

Key Features:

High tensile strength with elongation ≤3%

Excellent acid and alkali resistance

Anti-static and flame-retardant when used in mining environments

Strong bonding and uniform load distribution

Applications:

Used for soft soil reinforcement, subgrade stabilization, and stress distribution in roads, railways, ports, airports, and municipal projects.

Also suitable for underground mining reinforcement and tunnel linings.

PET Geogrid Regular Model Specifications

| مواصفة | Tensile Strength ≥ (kN/m) | Elongation at Break ≤ (%) | Strength at 2% Strain ≥ (kN/m) | Strength at 5% Strain ≥ (kN/m) |

|---|---|---|---|---|

| PETG20 | 20 | 12 | 6 | 12 |

| PETG35 | 35 | 12 | 10 | 20 |

| PETG50 | 50 | 12 | 15 | 28 |

| PETG80 | 80 | 13 | 24 | 45 |

| PETG100 | 100 | 13 | 30 | 59 |

| PETG125 | 125 | 13 | 37 | 78 |

| PETG150 | 150 | 13 | 45 | 96 |

| مواصفة | Tensile Strength ≥ (kN/m) | Elongation at Break ≤ (%) | Strength at 2% Strain ≥ (kN/m) | Strength at 5% Strain ≥ (kN/m) |

|---|---|---|---|---|

| BXG20 | 20 | 13 | 7 | 14 |

| BXG35 | 35 | 13 | 12 | 24 |

| BXG50 | 50 | 13 | 17 | 34 |

| BXG80 | 80 | 13 | 28 | 56 |

| BXG100 | 100 | 13 | 35 | 70 |

| BXG125 | 125 | 14 | 43 | 86 |

| BXG150 | 150 | 14 | 52 | 104 |

Steel Plastic Geogrid Regular Model Specifications

| Model | Ultimate Tensile Strength (kN/m) | Elongation at Break (%) | After 100 Freeze–Thaw Cycles Tensile Strength (kN/m) |

After 100 Freeze–Thaw Cycles Elongation at Break (%) |

Mesh Aperture (mm) | Cold Resistance (°C) | Peel Strength (N) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | Index | Glue/Weld | |

| PSG30-30 | 30 | 30 | ≤3 | ≤3 | 30 | 30 | ≤3 | ≤3 | 232 | 232 | -35 | ≥100 |

| PSG40-40 | 40 | 40 | ≤3 | ≤3 | 40 | 40 | ≤3 | ≤3 | 149 | 149 | -35 | ≥100 |

| PSG50-50(A) | 50 | 50 | ≤3 | ≤3 | 50 | 50 | ≤3 | ≤3 | 220 | 220 | -35 | ≥100 |

| PSG50-50(B) | 50 | 50 | ≤3 | ≤3 | 50 | 50 | ≤3 | ≤3 | 125 | 125 | -35 | ≥100 |

| PSG60-60(A) | 60 | 60 | ≤3 | ≤3 | 60 | 60 | ≤3 | ≤3 | 170 | 170 | -35 | ≥100 |

| PSG60-60(B) | 60 | 60 | ≤3 | ≤3 | 60 | 60 | ≤3 | ≤3 | 107 | 107 | -35 | ≥100 |

| PSG70-70 | 70 | 70 | ≤3 | ≤3 | 70 | 70 | ≤3 | ≤3 | 137 | 137 | -35 | ≥100 |

| PSG80-80 | 80 | 80 | ≤3 | ≤3 | 80 | 80 | ≤3 | ≤3 | 113 | 113 | -35 | ≥100 |

| PSG100-100 | 100 | 100 | ≤3 | ≤3 | 100 | 100 | ≤3 | ≤3 | 95 | 95 | -35 | ≥100 |

Why Choose WP Specialist?

Over the years, WP Specialist has established itself as one of China’s reliable geogrid manufacturers and trusted suppliers of geosynthetic reinforcement materials for global infrastructure projects.

We specialize in producing high-performance geogrids designed to improve soil stability, load-bearing capacity, and long-term performance in retaining walls, slopes, embankments, and road foundations.

Our geogrids deliver exceptional tensile strength, creep resistance, and durability - مدعومة بإمدادات المصنع مباشرة، والتوجيه الفني المهني، ومراقبة الجودة الصارمة.

- Free Samples of Polyester Geogrid

- دعم المشروع الخبراء

- ضمان جودة موثوق

- أكثر من 10 سنوات من الخبرة في التصنيع

- توريد المصنع مباشرة

جاهز لتحديد Geogrid?

- أكثر من 15 عامًا من الخبرة المباشرة في المصنع

- حلول مخصصة لتلبية احتياجاتك

- الشحن العالمي & الدعم اللوجستي

- اقتباس شفاف ، لا يوجد تبديل

- 100 ٪ خبر مضمون

سيتم الاحتفاظ بمعلومات بريدك الإلكتروني في سرية تامة وسيضمن موظفو الأعمال لدينا أن معلوماتك الخاصة آمنة تمامًا!

اتصال

- info@waterprackspecialist.com

الرد في غضون 12 ساعة!

يرجى الانتباه إلى البريد الإلكتروني مع اللاحقة "@waterprackspecialist.com".