Choosing the wrong geomembrane thickness can be a costly mistake. Under-specifying leads to punctures and leaks, risking environmental damage and expensive repairs. Over-specifying wastes your budget on performance you don't need, increasing material and installation costs without adding real value. This guide provides a clear, practical framework to help you select the optimal HDPE geomembrane thickness, balancing durability, regulatory compliance, and cost-effectiveness for your specific project.

This guide explains how to select the right HDPE geomembrane thickness by covering industry standards, key influencing factors like load and exposure, and typical applications. We will break down the performance trade-offs and common mistakes to help you make an informed, data-driven decision for a durable and cost-efficient containment system.

The thickness of a geomembrane is one of its most critical physical properties, but it's often misunderstood. A thicker liner isn't always the better choice. The right selection depends on a thorough analysis of your project's unique demands.

HDPE Geomembrane Thickness and Its Role in Liner Performance

Geomembrane thickness is more than just a measurement; it's a primary indicator of a liner's physical robustness and its ability to withstand the stresses of installation and long-term service. This single parameter directly influences several key performance characteristics that determine the success and longevity of a containment project.

In my experience, thickness is the first line of defense against mechanical damage. A thicker liner provides a more substantial barrier against punctures from sharp rocks in the subgrade or angular materials in the cover soil. As a general rule, critical mechanical properties like puncture resistance, tensile strength, and tear resistance all increase proportionally with geomembrane thickness. This added strength provides a greater margin of safety during the demanding construction phase and enhances the liner's ability to resist long-term stresses from soil settlement or heavy loads. Ultimately, a properly selected thickness contributes directly to the overall service life of the containment system by ensuring its physical integrity from day one.

Industry Standards and Common Thickness Specifications (mm & mil)

When specifying or purchasing الغشاء الجيومومومبرين HDPE, you will encounter two units of measurement for thickness: millimeters (mm) and mils. One mil is equal to one-thousandth of an inch (0.001"). Since we work with clients globally, being comfortable with both is essential.

Here is a quick conversion chart for the most common HDPE geomembrane thicknesses:

- 0.5 mm = 20 mil

- 0.75 mm = 30 mil

- 1.0 mm = 40 mil

- 1.5 mm = 60 mil

- 2.0 mm = 80 mil

- 2.5 mm = 100 mil

- 3.0 mm = 120 mil

Industry standards, such as the Geosynthetic Institute's GSI-GM13 specification, play a vital role in ensuring quality. However, it's crucial to understand that standards like GM13 define the minimum physical and mechanical properties a geomembrane must possess (e.g., density, tensile strength, carbon black content). They do not mandate a specific thickness for any given application. The choice of thickness remains a project-specific engineering decision. That's why simply asking for a "GM13 certified liner" isn't enough; you must also specify the thickness that your project calculations demand.

Factors Influencing Thickness Selection: Design, Load, and Exposure

The idea that "thicker is always better" is a common misconception that can lead to inefficient and overly expensive designs. The optimal thickness is a carefully calculated balance of several site-specific factors.

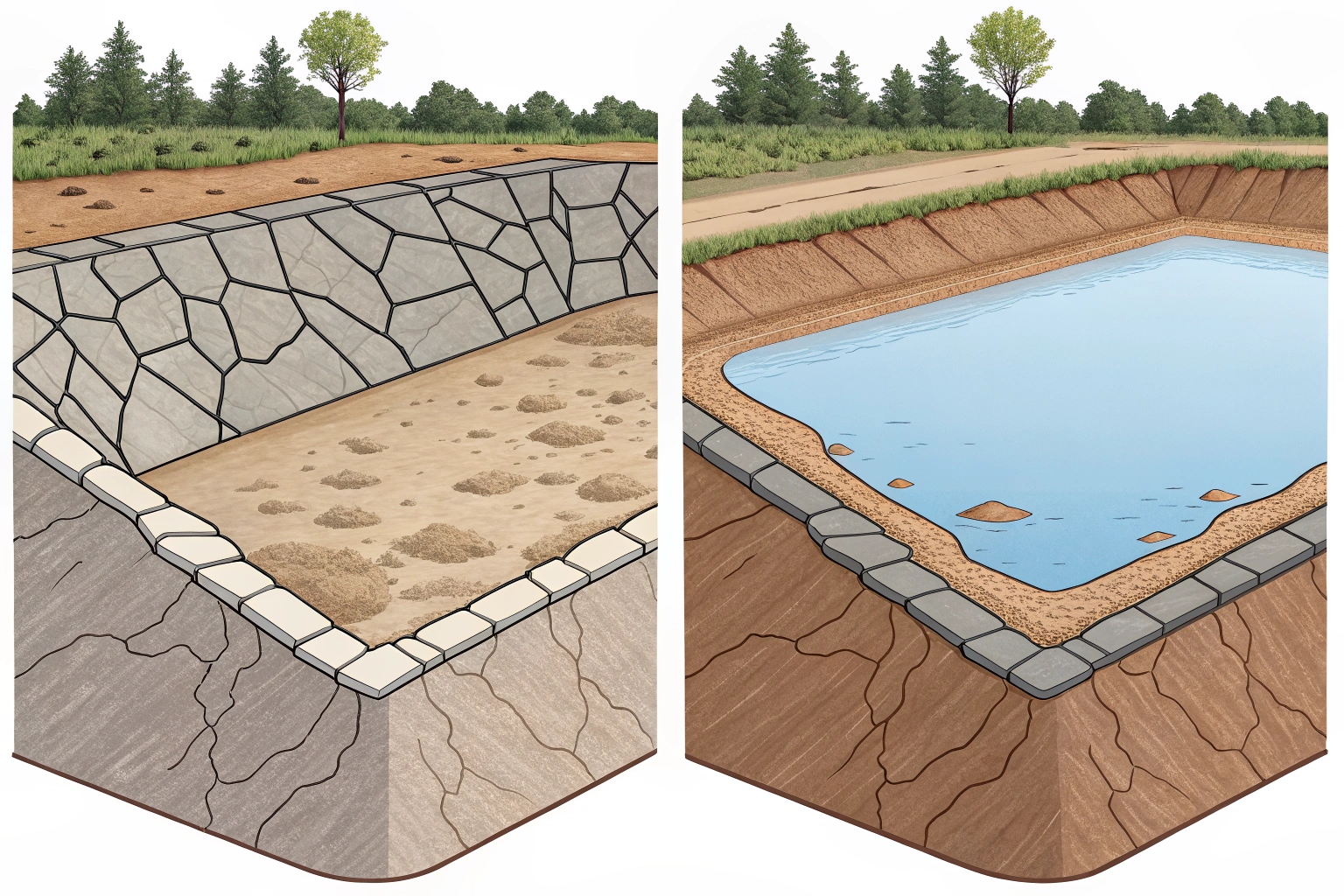

Subgrade Conditions

The quality of the surface beneath the liner is a primary consideration. A subgrade with sharp, angular rocks or construction debris will require a thicker geomembrane to provide adequate puncture resistance. Conversely, a project with a smooth, well-compacted sand or geotextile cushion layer may allow for a slightly thinner, more economical liner.

Applied Loads

Consider what will be placed on top of the geomembrane. The depth and type of cover soil, the potential for heavy vehicle traffic during or after construction, and the hydrostatic pressure in deep ponds all contribute to the mechanical stress on the liner. Higher loads demand greater tensile strength and puncture resistance, which are best achieved with a thicker membrane.

Chemical and UV Exposure

While HDPE is known for its excellent chemical resistance, a thicker geomembrane provides a longer diffusion path, slowing the rate at which aggressive chemicals can migrate through the liner. For exposed liners without a protective soil cover, a thicker material provides superior resistance to UV degradation and weathering over the project's lifespan.

Regulatory Requirements

For many critical containment applications, minimum thickness is mandated by law. For example, the U.S. Environmental Protection Agency (EPA) requires a minimum thickness of 60 mil (1.5 mm) for HDPE geomembrane liners used in municipal solid waste landfills to ensure adequate protection against leachate leakage. Always verify local and national regulations first.

Typical Thickness by Application: From Light Protection to Heavy-Duty Containment

To make the selection process more tangible, let's look at how thickness corresponds to real-world applications. Based on thousands of projects we've supplied, a clear pattern emerges.

-

0.5 mm - 0.75 mm (20-30 mil): Light-Duty Applications

This range is ideal for projects where high flexibility and cost-effectiveness are priorities, and mechanical stress is low. Think of agricultural irrigation channels, small decorative ponds, and temporary water containment where the subgrade is well-prepared. -

1.0 mm - 1.5 mm (40-60 mil): General Containment

This is the "workhorse" range, offering a robust balance of durability, puncture resistance, and installability. It's the most common choice for medium-sized projects such as aquaculture ponds, canal linings, and secondary containment berms. The 1.5 mm thickness is the starting point for most regulated landfills. -

1.5 mm - 2.5 mm (60-100 mil): Heavy-Duty Containment

When durability and long-term security are paramount, this thickness range is required. It is the standard for large-scale projects like municipal solid waste landfills, mining heap leach pads, and large wastewater treatment lagoons where the consequences of a failure are severe. -

2.0 mm - 3.0 mm (80-120 mil): Extreme-Duty & Critical Containment

This is reserved for the most demanding applications. This includes primary containment for petroleum storage tank farms, liners for aggressive chemical solutions, and high-risk mining waste facilities. The extreme thickness provides the maximum possible resistance to puncture, chemical attack, and long-term degradation.

Performance Comparison: Thin vs. Thick Geomembranes

Choosing a thickness always involves trade-offs. Understanding these differences is key to specifying the right material for your project's performance and budget needs. A thicker geomembrane is not universally superior; it excels in some areas but is less optimal in others.

| ملكية | Thinner Geomembrane (e.g., 0.75 mm) | Thicker Geomembrane (e.g., 2.0 mm) | ملحوظات |

|---|---|---|---|

| مقاومة الثقب | أدنى | أعلى | Critical for rocky subgrades or sharp cover material. |

| قوة الشد | أدنى | أعلى | Important for resisting stresses from soil settlement and heavy loads. |

| Chemical Resistance | Good (Shorter Diffusion Path) | Excellent (Longer Diffusion Path) | Thicker liners offer better long-term protection against harsh chemicals. |

| المرونة | أعلى | أدنى | Thinner liners are easier to conform to complex shapes and corners. |

| Installation Ease | Easier to handle | More Difficult | Heavier rolls require larger equipment and more labor to deploy. |

| Material Cost | أدنى | أعلى | Cost increases directly with the amount of resin used. |

Economic and Installation Considerations for Different Thicknesses

Performance requirements must be weighed against practical and economic realities. The cost of a geomembrane project is not limited to the price per square meter of the material itself.

As geomembrane thickness increases, several associated costs also rise:

- Material Cost: This is the most obvious factor. A 2.0 mm liner contains twice the raw material as a 1.0 mm liner, and its price reflects that.

- Transportation Costs: Thicker geomembranes result in significantly heavier and shorter rolls. This means more rolls are needed to cover the same area, leading to higher shipping and freight charges, especially for international projects.

- Installation Labor & Equipment: Deploying heavy 2.0 mm or 2.5 mm rolls requires larger cranes or loaders. The material is also stiffer and more difficult to position, which can slow down the installation crew. Welding thicker material also requires more heat energy and slightly more time per seam.

The goal is to find the project's sweet spot: the most economical thickness that meets all technical and regulatory requirements without being excessively difficult or costly to install.

Case Insights: Common Mistakes in Over- or Under-Specifying Thickness

In our work, we often see two common and costly mistakes related to thickness selection. Avoiding them is key to a successful project.

The first mistake is under-specifying. A client might choose a 0.75 mm liner for a pond with a poorly prepared, rocky subgrade in an attempt to save on initial material costs. This seemingly small saving is quickly erased when the liner is punctured during installation or by the placement of cover soil. The subsequent costs of finding the leak, patching the liner, and repairing any environmental damage far exceed the initial savings.

The second mistake is over-specifying. For a small landscape pond on a perfectly smooth, sand-bedded subgrade, specifying a 2.5 mm liner is a classic example of "over-engineering." The extreme puncture resistance and strength are unnecessary for this low-stress environment. The project owner ends up paying a premium for material, shipping, and installation labor for performance benefits they will never use.

Expert Recommendations for Optimized Thickness Selection

To avoid these mistakes and confidently choose the right thickness, we recommend a systematic approach. Before making a decision, a project engineer, buyer, or contractor should answer the following questions:

- What are the regulatory requirements? Start here. Check local and national environmental laws to determine the minimum legal thickness for your application (e.g., landfill, mining). This is non-negotiable.

- What is the subgrade condition? Be honest about the site. Is the subgrade composed of uniform sand, or is it rough soil with angular rocks? The rougher the surface, the thicker the liner needs to be.

- What are the applied loads? Define the weight and type of material that will sit on the liner. This includes cover soil depth, vehicle traffic, and water depth (hydrostatic pressure).

- What is the exposure level? Will the liner be fully exposed to the sun or buried under a protective soil layer? Exposed applications demand thicker material for long-term UV resistance.

- What is the project's required design life? A temporary construction pond has very different needs than a landfill designed to perform for 50+ years. Generally, a longer design life warrants a thicker, more durable liner.

- Have you consulted an expert? Don't hesitate to leverage the experience of your geosynthetics supplier. We can review your project data and provide a recommendation based on thousands of similar projects, helping you find the most efficient and reliable solution.

Summary Table: HDPE Geomembrane Thickness vs. Application Scenarios

To bring it all together, here is a quick reference table. Use this as a starting point to guide your selection process, but always validate it with a site-specific analysis.

| Application | Typical Thickness (mm) | Typical Thickness (mil) | Key Considerations |

|---|---|---|---|

| Agricultural Irrigation / Small Ponds | 0.5 - 0.75 mm | 20 - 30 mil | High flexibility for conforming to terrain, cost-effectiveness. |

| Aquaculture Ponds / Canal Liners | 0.75 - 1.0 mm | 30 - 40 mil | A good balance of durability and flexibility for moderate conditions. |

| Medium-Sized Landfills / Pond Liners | 1.0 - 1.5 mm | 40 - 60 mil | Standard choice for good puncture resistance and general durability. |

| Municipal Solid Waste Landfills | ≥ 1.5 mm | ≥ 60 mil | Often a regulatory minimum. High stress and puncture resistance. |

| Mining Heap Leach Pads | 1.5 - 2.0 mm | 60 - 80 mil | Requires high resistance to puncture, tearing, and chemicals. |

| Wastewater Treatment Lagoons | 1.5 - 2.5 mm | 60 - 100 mil | Needs excellent long-term chemical resistance and durability. |

| Exposed Covers / Landfill Caps | 2.0 - 2.5 mm | 80 - 100 mil | Demands maximum UV resistance and ability to withstand weather extremes. |

| Critical / Chemical Containment | 2.0 - 3.0 mm | 80 - 120 mil | For high-risk areas needing maximum resistance to chemicals and puncture. |

خاتمة

Selecting the right HDPE geomembrane thickness is a critical engineering decision, not a simple choice of "thicker is better." The optimal thickness is the one that meets all regulatory, load, and exposure requirements without excessive cost or installation difficulty. By conducting a thorough site analysis and consulting with experts, you can specify the smartest, most cost-effective liner for a successful and long-lasting containment project.