Die gebruik van die verkeerde tipe geosel kan jou projek verwoes. As jy dreinering benodig en 'n soliede wandsel gebruik, kan jy 'n massiewe waterdrukopbou en hellingsversaking veroorsaak.

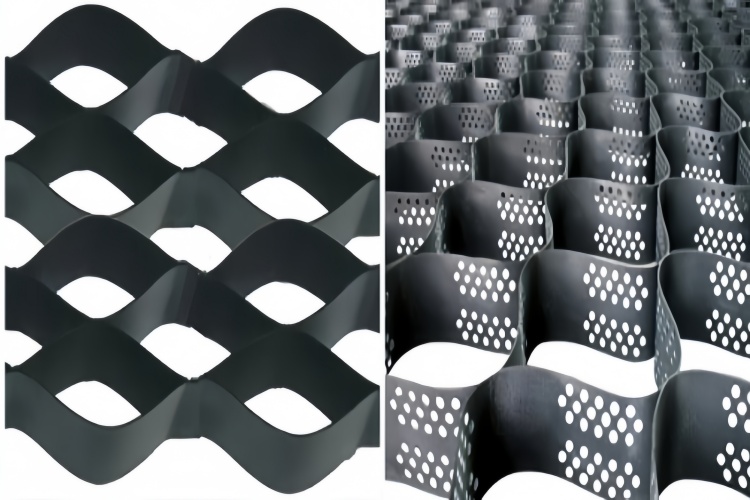

Geperforeerde geoselle het gate in hul selwande, wat water, lug en wortels toelaat om deur te gaan. Nie-geperforeerde geoselle het soliede mure, wat heeltemal aparte, ingeslote kompartemente skep. Hierdie enkele verskil dikteer hul geskiktheid vir heeltemal verskillende ingenieurstoepassings.

As 'n geosintetiese verskaffer, Ek moet hierdie punt dikwels met kliënte uitklaar. Dit is 'n eenvoudige onderskeid met groot gevolge. ’n Geperforeerde geosel is ontwerp vir hidrouliese verbinding en om dinge daardeur te laat groei, wat dit perfek maak vir begroeide hellings en dreinering. ’n Nie-geperforeerde geosel is ontwerp vir absolute inperking en skeiding, wat dit die keuse maak vir swaar vragondersteuning op padbasisse of om ondeurdringbare lae te skep. Dink so daaraan: geperforeerd is vir dreinering en plantegroei, nie-geperforeerd is vir sterkte en inperking.

Watter strukturele kenmerke onderskei geperforeerde van nie-geperforeerde geoselle?

Van 'n afstand af lyk albei tipes geoselle na dieselfde heuningkoekstruktuur. Die kritieke verskil is in die selwande, en dit is 'n kenmerk wat jy van naby kan sien en voel.

Die enigste strukturele verskil is die teenwoordigheid van klein, gereeld gespasieerde gate, of perforasies, langs die vertikale wande van die geoselstroke. Nie-geperforeerde geoselle het heeltemal soliede, aaneenlopende mure.

Hierdie een kenmerk - gate of geen gate - verander fundamenteel hoe die geosel in wisselwerking tree met die materiaal waarmee jy dit vul, sowel as met die omliggende omgewing.

| Kenmerk | Geperforeerde Geocell | Nie-geperforeerde Geocell |

|---|---|---|

| Selwandstruktuur | Het sistematiese perforasies/gate (tipies 3-10mm deursnee) | Soliede, verseëlde en deurlopende mure. |

| Hidrouliese vloei | Water, lug en voedingstowwe kan tussen aangrensende selle vloei. | Water en materiale word binne elke individuele sel geïsoleer. |

| Deurlaatbaarheid | Hoë deurlaatbaarheid. Die hele stelsel dreineer vrylik. | Lae tot geen deurlaatbaarheid. Skep 'n reeks ingeslote kompartemente. |

| Primêre funksie | Erosiebeheer, begroeide hellings, dreineringsbestuur. | Vragondersteuning, opsluiting, skeiding. |

The perforations allow adjacent cells to become interconnected, creating a single, unified system that can drain freely and support a continuous root mass for vegetation. The solid walls of a non-perforated geocell create a series of independent "boxes" wat maksimum opsluiting bied vir invulmateriaal soos aggregaat, wat dit uitstekende drakrag gee.

Hoe verskil die meganiese en hidrouliese werkverrigtingeienskappe?

Om tussen die twee tipes te kies, beteken om te verstaan hoe gate sterkte en watervloei beïnvloed. Dit is 'n kompromis tussen hidrouliese werkverrigting en absolute opsluiting.

Geperforeerde geoselle bied uitstekende hidrouliese werkverrigting en beter grond-tot-selwand wrywing. Nie-geperforeerde geoselle bied maksimum inperking en effens hoër treksterkte langs die selwand self.

Kom ons breek die belangrikste prestasieverskille af:

Geperforeerde Geocell Voordele:

- Uitstekende dreinering: Dit is hul grootste voordeel. Water kan lateraal deur die gate beweeg, wat voorkom dat hidrostatiese druk binne die stelsel opbou. Dit is van kardinale belang vir die stabiliteit van hellings en keermure.

- Verbeterde wrywingsweerstand: Die grond of aggregaatvulling kan deur die perforasies druk, wat 'n sterk meganiese ineenskakeling met die selwand skep. Dit verhoog die skuifweerstand en algehele styfheid van die geoselstelsel. Studies toon dit kan versterkingsdoeltreffendheid met 10-20% verbeter.

- Plantegroei ondersteuning: Die gate laat plantwortels van die een sel na die volgende groei, wat 'n sterk, onderling gekoppelde wortelmat skep wat die grond op hellings verder stabiliseer.

Nie-geperforeerde Geocell Voordele:

- Maksimum opsluiting: Met soliede mure word die invulmateriaal heeltemal binne elke sel vasgevang. Dit bied die hoogste moontlike inperking, wat dit ideaal maak vir die versterking van padbasisse waar die stelsel onder intense, herhaalde laai is.

- Totale skeiding: Omdat die selle geïsoleer is, kan dit gebruik word om 'n ondeurdringbare of lae deurlaatbaarheidslaag te skep, byvoorbeeld wanneer dit met beton of 'n kleimengsel gevul word.

- Effens hoër muursterkte: Met geen gate nie, het die plastiekstrook van die geoselwand 'n effens hoër treksterkte, wat 'n faktor in baie hoë keermure kan wees.

In watter ingenieurstoepassings is elke tipe geosel die geskikste?

Die gebruik van die verkeerde geosel vir die werk kan lei tot enigiets van 'n verspoelde helling tot 'n mislukte padbasis. Die aansoek moet die keuring aandryf.

Gebruik geperforeerde geoselle vir begroeide hellings, kanaalbeskerming en keermure waar dreinering van kritieke belang is. Gebruik nie-geperforeerde geoselle vir padbasisversterking, spoorwegondergronde en lassteunplatforms waar maksimum inperking die prioriteit is.

Hier is 'n duidelike gids om jou te help om die regte tipe te kies gebaseer op algemene toepassings:

| Toepassing | Aanbevole Geocell Tipe | Hoekom? |

|---|---|---|

| Groen Hellings / Herplanting | Geperforeerde | Laat wortels verbind en water dreineer, wat 'n stabiele, lewende erosiebeheerstelsel skep. |

| Rivieroewer & Kanaalbeskerming | Geperforeerde | Voorkom waterdrukopbou agter die selle en maak voorsiening vir 'n meer natuurlike, begroeide voorkoms. |

| Padbasis / Ondergrondversterking | Nie-geperforeerde | Verskaf maksimum inperking van die totale basislaag, wat 'n stywe, stabiele platform skep om spore te verminder. |

| Spoorweg Subgrade | Nie-geperforeerde | Die uiterste dinamiese vragte van treine vereis die hoogste vlak van inperking om ballasvervorming te voorkom. |

| Keermure | Geperforeerde | Kritiek om dreinering toe te laat om hidrostatiese druk te voorkom, wat 'n hoofoorsaak van muurversaking is. |

| Vullisdoppies / deksels | Geperforeerde | Ondersteun die groei van 'n vegetatiewe bedekking terwyl stortingsterreingasse uitlaat en reënwater behoorlik dreineer. |

Hoe kan ek tussen die twee kies op grond van projekspesifieke toestande?

Die finale besluit kom daarop neer om 'n paar eenvoudige vrae oor jou projek se doelwitte te beantwoord. Gaan dit oor die bestuur van water en plantegroei, of gaan dit oor pure krag en lasondersteuning?

Om die regte geosel te kies, bepaal eers of jou primêre behoefte aan dreinering en plantegroei is. Indien wel, kies geperforeerde. As jou primêre behoefte is vir maksimum las opsluiting en skeiding, kies nie-geperforeerde.

Hier is 'n eenvoudige besluitproses wat ek met my kliënte gebruik:

-

Is plantegroei deel van die finale ontwerp?

- Ja: Jy moet 'n gebruik geperforeer geosel. Die wortels moet deur die selwande kan groei om 'n stabiele mat te vorm.

- Nee: Gaan na die volgende vraag.

-

Sal die geosel teen 'n helling of in 'n kanaal wees waar waterdreinering belangrik is?

- Ja: Jy benodig 'n geperforeer geocell om waterdruk opbou te voorkom en die stabiliteit van die hele stelsel te verseker.

- Nee: Gaan na die volgende vraag.

-

Is die hoofdoel om 'n stywe, sterk basis vir 'n pad-, spoor- of swaartoerustingplatform te skep?

- Ja: Jy benodig 'n nie-geperforeerde geosel. Jou doel is om die hoogste moontlike inperking van die aggregaatvulling te bereik vir maksimum dravermoë.

- Nee: Her-evalueer jou projekbehoeftes. Die meeste aansoeke sal in een van die kategorieë hierbo val.

Deur hierdie logika te volg, kan jy maklik bepaal watter tipe geosel die beste geskik is om die werkverrigting en langtermynbetroubaarheid te verskaf wat jou spesifieke projek vereis.

Gevolgtrekking

Die keuse is duidelik: gebruik geperforeerde geoselle vir toepassings wat dreinering en plantegroei benodig, soos hellings en kanale. Gebruik nie-geperforeerde geoselle vir toepassings wat maksimum sterkte en inperking benodig, soos padbasisse.