Unstable soil and poor drainage can ruin a project. Without the right solution, your roads crack and your retaining walls fail. Geotextiles are the simple, effective answer.

Geotextile fabric is a permeable textile used with soil to improve project performance. It works by performing key functions like separation, filtration, and reinforcement, ensuring the long-term stability and durability of civil engineering structures like roads, walls, and drainage systems.

I've shipped countless containers of geotextiles, and the most common question I get is "How can a simple piece of fabric do so much?" It's not magic; it's smart engineering. The fabric is designed to solve specific problems with the ground itself. Understanding exactly what it is and how it functions is the key to selecting the right material for your next project. Let's break down the fundamentals.

What is geotextile fabric and how is it defined in civil engineering?

Trying to build on poor ground without the right materials is a recipe for failure. Structures settle, roads rut, and drainage clogs, all leading to expensive, long-term problems.

In civil engineering, a geotextile is defined as a permeable, synthetic fabric designed for use with soil, rock, or other geotechnical materials. Its primary purpose is to act as an integral part of a man-made project, structure, or system to solve ground-related problems.

A Key Component in Modern Construction

From my perspective as a supplier, a geotekstiel is one of the most versatile tools in the geosynthetics family. Unlike an impermeable geomembrane, which is designed to block water, a geotextile is defined by its ability to let water pass through in a controlled way. In engineering terms, it's a planar, porous textile. We place it in or on the ground to improve the soil's behavior. Think of it as a specialized fabric that enhances the ground's natural properties. Its formal definition always centers on its use in conjunction with soil. It’s not just a textile; it's a textile with a specific geotechnical job to do. Whether it's preventing two soil layers from mixing or reinforcing a weak slope, its role is always to improve the mechanical or hydraulic performance of the ground.

What materials are commonly used to produce geotextile fabrics?

Using a geotextile made from the wrong material can lead to rapid degradation from chemicals or sunlight. This compromises the entire structure it was meant to protect or reinforce.

The most common materials are synthetic polymers, primarily polypropylene (PP) and polyester (PET). These materials are chosen for their durability, chemical inertness, and resistance to biological decay, ensuring a long service life when buried in the ground.

Choosing Between Polypropylene and Polyester

When my clients are deciding on a geotextile, the discussion almost always comes down to these two polymers. Over 95% of the geotextiles we export are made from one of them. While they may seem similar, they have key differences that make them suitable for different jobs.

- Polypropylene (PP): This is the workhorse of the industry. It's lightweight, cost-effective, and has excellent chemical resistance, especially against acids and alkalis found in soil. This makes it the go-to choice for most standard separation, filtration, and general stabilization jobs.

- Polyester (PET): Polyester's main advantage is its superior strength and resistance to creep (the tendency to stretch slowly over time under a constant load). This makes PET the preferred material for critical, long-term reinforcement applications, like in high retaining walls or steep embankments where the fabric is under constant high tension.

| Materiaal | Key Strengths | Common Applications |

|---|---|---|

| Polipropileen (PP) | Excellent chemical resistance, economical, good all-around performance. | Separation, filtration, drainage, road stabilization. |

| Polyester (PET) | High tensile strength, low creep, excellent UV resistance. | High-strength reinforcement, retaining walls. |

What are the main characteristics and performance advantages of geotextiles?

Designing a project without considering soil mechanics can lead to unpredictable results. The ground can shift, water can build up, and layers can mix, causing structural instability over time.

The main characteristics are its mechanical properties (strength, puncture resistance) and hydraulic properties (permeability, pore size). These translate into performance advantages like improved structural stability, extended project lifespan, and reduced construction and maintenance costs.

The Five Core Functions

The true advantage of a geotextile comes from the jobs it can perform. We describe its performance by breaking it down into five core functions. I always walk clients through these to make sure they're selecting a product that matches their primary need.

| Characteristic / Function | Performance Advantage |

|---|---|

| Separation | Prevents mixing of soil layers, preserving the strength and drainage of expensive aggregate. |

| Filtrering | Allows water to pass through while retaining soil particles, preventing drainage systems from clogging. |

| Reinforcement | Adds tensile strength to soil, increasing its load-bearing capacity and stability. |

| Drainage | Collects and transmits fluids along the plane of the fabric, dewatering saturated soils. |

| Beskerming | Acts as a cushion to protect liners (geomembranes) from puncture and abrasion damage. |

By performing these functions, geotextiles offer a massive advantage over traditional construction methods. They often reduce the need for thick layers of expensive aggregate, simplify construction, and create a final structure that performs better and lasts longer with less maintenance.

How does geotextile fabric work to separate, filter, and reinforce soil structures?

It's hard to believe that a simple fabric can stop a road from failing or a wall from collapsing. Without understanding the mechanics, it seems too good to be true.

Separation works by providing a physical barrier. Filtration works like a coffee filter, letting water through while holding soil. Reinforcement works like rebar in concrete, adding tensile strength to the soil mass and distributing loads.

A Deeper Look at the Mechanisms

Let's break down exactly how the three primary functions work on a mechanical level.

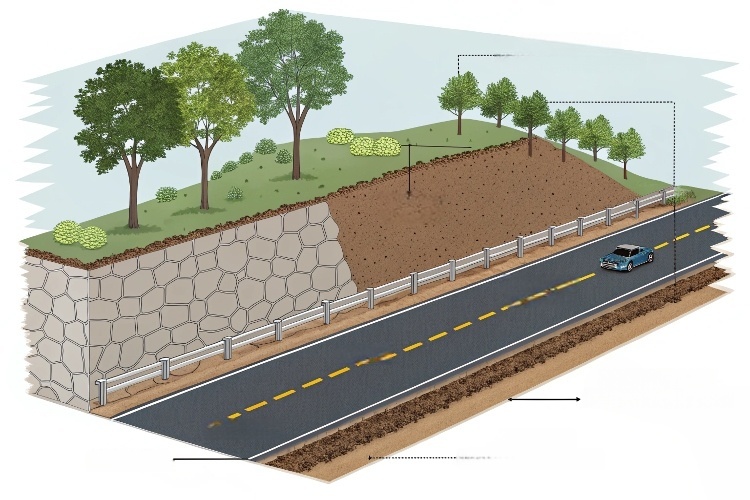

The Separation Mechanism

Imagine placing a layer of expensive, clean gravel directly onto soft, muddy ground for a new road. Without a geotextile, traffic pushes the gravel down into the mud, and mud pumps up into the gravel. The geotextile acts as a physical barrier that stops this intermixing. It keeps the two materials permanently separate, preserving the integrity and drainage capacity of your gravel base course. This simple function is one of the most effective ways to extend the life of any road.

Die Filtration Mechanism

This is where non-woven geotextiles shine. Their structure is a three-dimensional maze of fibers with carefully controlled pore sizes. When water carrying silt flows toward the fabric, the water easily passes through, but the soil particles are trapped. It works like a coffee filter, but it's even smarter. Over time, a natural soil filter develops right against the geotextile, which helps it remain unclogged for decades, ensuring water pressure can always be relieved from behind retaining walls or in drainage trenches.

The Reinforcement Mechanism

Soil is strong when you push on it (compression) but very weak when you pull on it (tension). A high-strength woven geotextile adds this missing tensile strength. When placed in layers within the soil, it acts like rebar in concrete. When a heavy load is applied, the fabric goes into tension, spreading the load over a much wider area. It also physically holds the soil particles together, preventing them from shifting apart.

Gevolgtrekking

Geotextile fabric is a versatile engineering tool. It solves soil problems by separating, filtering, reinforcing, and draining. Understanding how it works helps you choose the right product for your project.