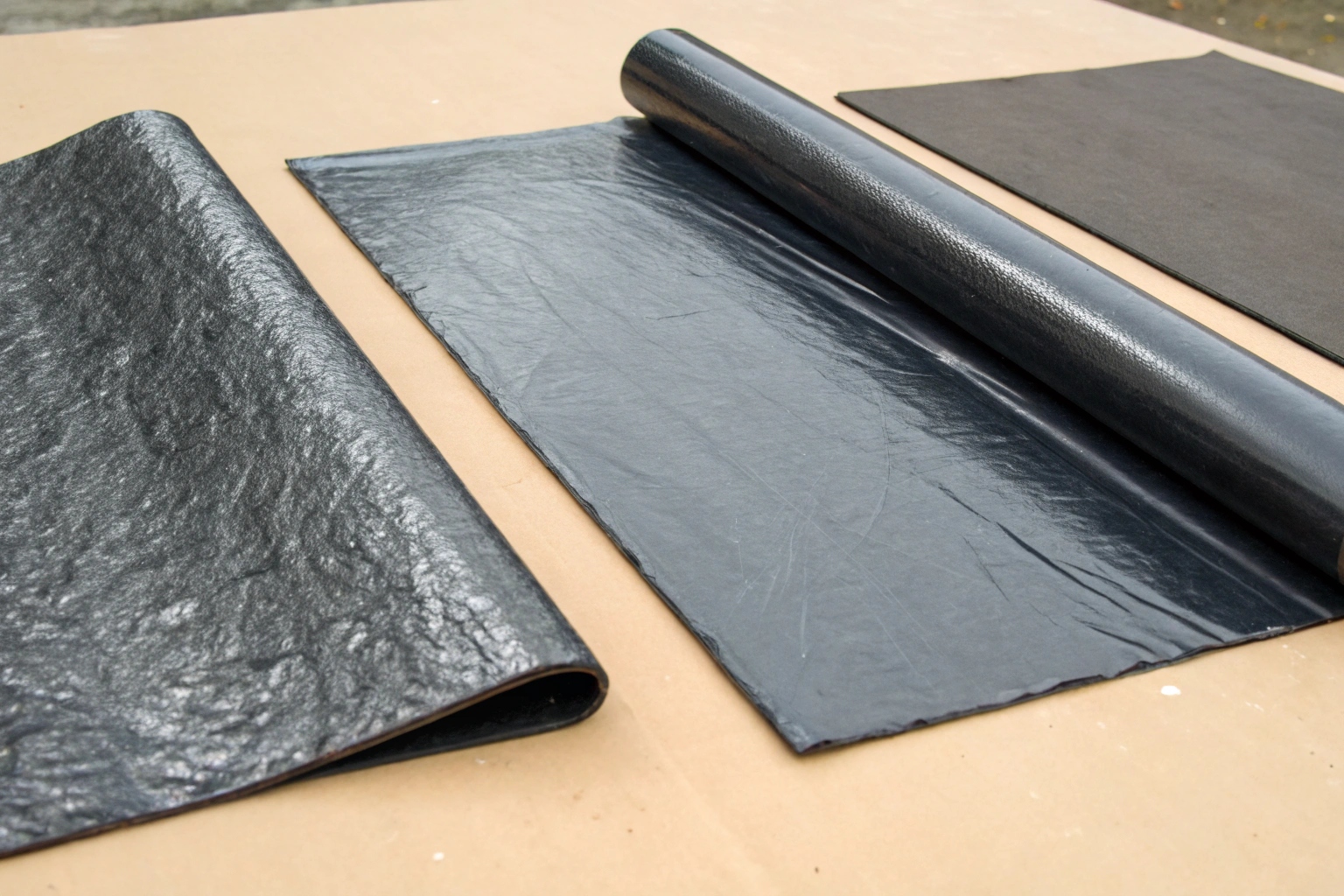

Sourcing HDPE geomembrane seems simple, but a bad purchase can cause catastrophic project failure. Leaks and costly repairs are a nightmare. This guide reveals the critical pitfalls to avoid.

Avoid pitfalls by looking beyond the "HDPE" label. Verify key specs like virgin resin content, stress-crack resistance (ESC) data, and true thickness tolerance. Always demand manufacturer certifications and third-party test reports. Prioritizing documented quality over the lowest price prevents costly long-term failures.

The lowest price is often the most expensive mistake. Many importers focus only on cost-per-square-meter, overlooking the technical details that determine a liner's 30-year performance. A cheap liner made with recycled resin or inadequate UV protection will degrade and fail, turning initial savings into a massive liability. Understanding what to look for—and what to look uit for—is the key to a successful, long-lasting project.

What key product specifications should I check before purchasing HDPE geomembranes?

A technical data sheet is full of numbers. Ignoring the critical ones means you could be buying a product that is fundamentally unsuitable for your project, even if it's labeled "HDPE."

Focus on four critical specifications: Density (≥0.94 g/cm³), Resin Type (100% virgin), Carbon Black content (~2.5% for UV resistance), and Environmental Stress Crack Resistance (ESC). Never accept a product without a Manufacturer's Test Certificate (MTC) verifying these points.

These specifications are not negotiable; they are the foundation of the liner's long-term performance and durability. A supplier who cannot or will not provide clear data on these points is a major red flag.

| Specification | Why It's Critical | What to Look For |

|---|---|---|

| Resin Type | Virgin resin ensures maximum durability, chemical resistance, and lifespan. Recycled resin contains impurities that lead to premature failure. | 100% virgin polymer resin. Be wary of vague terms like "high quality." |

| Density | High density is what gives HDPE its strength and chemical resistance. Lower-density materials (LDPE/LLDPE) are not a suitable substitute. | ≥ 0.94 g/cm³. This is the standard for high-density polyethylene. |

| Stress-Crack (ESC) | This measures resistance to cracking under stress and chemical exposure. Poor ESC is a leading cause of long-term liner failure. | ASTM D5397 test results. Demand a high pass-hour rating. |

| Carbon Black | Provides crucial UV resistance for exposed applications. Poor dispersion or low content leads to rapid degradation in sunlight. | 2.0% - 3.0% content, well-dispersed. Usually black in color. |

How can I compare different HDPE geomembrane grades and thicknesses for my project?

Choosing between a 1.0mm and 1.5mm liner seems like a minor detail, but this decision directly impacts puncture resistance, durability, and cost. Over-specifying wastes money, while under-specifying guarantees failure.

Match the thickness directly to the project's risk level and subgrade conditions. Use thicker liners (≥1.5mm) for high-stress applications like landfills or where puncture risk is high. Thinner grades (0.75mm - 1.0mm) may suffice for less critical applications like garden ponds.

Thickness is your primary defense against physical damage during installation and throughout the project's life. The decision is a trade-off between cost and security.

Thickness Selection Guide:

- 0.5mm - 0.75mm: Suitable for low-risk applications with smooth subgrades and minimal physical stress, such as small decorative ponds or waterproofing under non-critical structures.

- 1.0mm: A common choice for reservoirs, irrigation canals, and aquaculture ponds where the subgrade is well-prepared and protected. It offers a good balance of cost and performance.

- 1.5mm: The industry standard for applications requiring high security and long-term performance. This is the minimum thickness typically specified for landfill base liners, mining leach pads, and critical environmental containment.

- 2.0mm - 3.0mm: Reserved for the most demanding conditions, such as projects with very rough subgrades, high potential for puncture, or where maximum chemical and physical durability is paramount.

What common pitfalls do buyers face when sourcing HDPE geomembranes from suppliers?

You've found a supplier with an unbelievably low price. Be warned: this price often conceals compromised materials, deceptive specifications, and a product that will not perform as promised.

The most common pitfalls are accepting products with recycled resin, thickness deception (tolerances outside the specified range), poor UV/antioxidant packages, and ignoring stress-crack resistance. Buying solely on the lowest price is the single biggest mistake an importer can make.

A savvy buyer knows how to spot the red flags that signal a low-quality product and an unreliable supplier.

Procurement Red Flags to Watch For:

- Vague Material Specs: The supplier simply says "HDPE" without specifying virgin resin. They are likely using cheaper, weaker recycled materials.

- Thickness or Weight Deception: The actual delivered product is thinner than specified or has wide negative tolerances. Always verify with a micrometer upon receipt.

- No ESC Testing: The supplier cannot provide Environmental Stress Crack Resistance test data. This indicates they are using a cheaper resin that is prone to long-term failure.

- The "Too Good to Be True" Price: A price far below the market average is a strong indicator of cut corners in raw materials, additives, or quality control.

- Missing Documentation: The supplier is hesitant to provide a full MTC, traceability records for resin batches, or ISO certifications.

How can I ensure stable quality and reliable delivery from my geomembrane manufacturer?

You've specified the perfect product on paper. But your project's success now depends on the manufacturer's ability to produce it consistently and deliver it on time.

Vet your supplier rigorously. Require ISO 9001 certifications, demand full material traceability for each roll, and reserve the right for third-party pre-shipment inspection. A detailed contract that specifies quality standards, delivery schedules, and penalties is your best protection.

Building a reliable supply chain is about creating a system of verification, not just trust.

Supplier Qualification Checklist:

- Verify Certifications: Ask for copies of their ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) certificates.

- Demand Traceability: Each roll should be labeled with a unique batch number. Insist on receiving the Manufacturer's Test Certificate (MTC) that corresponds to your specific batch before the shipment leaves the factory.

- Incorporate Third-Party Inspection: For large or critical orders, write a third-party inspection clause into your contract. Services like SGS can verify quality and quantity at the factory, giving you an unbiased report.

- Sign a Detailed Contract: Your purchase agreement should explicitly detail all key specifications (thickness, density, ESC, etc.), acceptable tolerances, packaging requirements, delivery deadlines, and clear penalties for non-compliance.

- Review Past Performance: Ask for references or case studies from similar projects in your region. A reputable manufacturer will have a proven track record.

Gevolgtrekking

Successful HDPE procurement goes beyond price. Verify virgin resin, demand stress-crack resistance data, and insist on full traceability. Vetting your supplier and their documentation prevents costly project failures.