Om 'n pad op sagte, onstabiele grond te bou is 'n nagmerrie. Vragmotors sit vas, die ondergrond verander in modder, en die duur aggregaat wat jy ingery het, verdwyn in die grond. Dit lei tot konstante, duur herstelwerk en 'n pad wat jare voor skedule misluk.

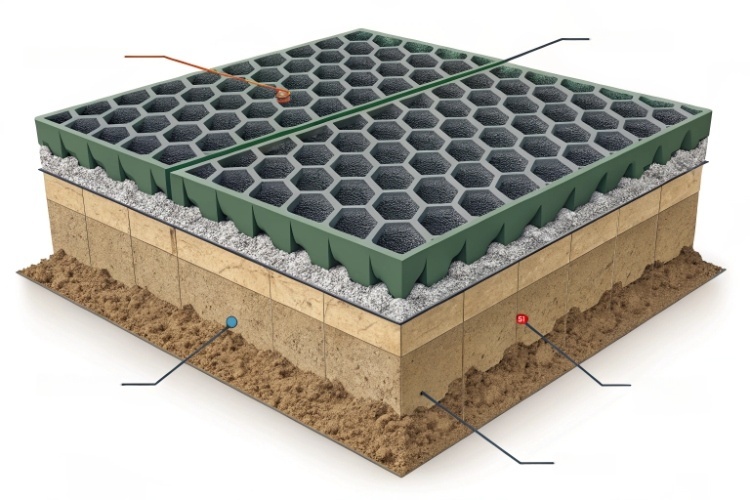

Geoselle stabiliseer paaie deur 'n 3D-heuningkoekstruktuur te skep wat die basismateriaal beperk. Hierdie sellulêre opsluiting versprei swaar vragte oor 'n wye area, wat spore voorkom, die hoeveelheid aggregaat wat benodig word, verminder en langtermyn onderhoudskoste drasties verminder.

As 'n geosintetiese verskaffer het ek gesien hoe talle projekte sukkel met swak subgrade. Die tradisionele oplossing is om tonne grond uit te grawe en te vervang, wat stadig en duur is. Geocells bied 'n slimmer manier. Hulle werk met die grond, nie daarteen nie, om 'n sterk, stabiele fondament te skep wat hou. Kom ons delf in hoe hierdie tegnologie jou tyd, geld en hoofpyn bespaar.

Hoe werk geoselle om swak of onstabiele padondergronde te versterk?

Jy word gekonfronteer met sagte, modderige grond wat amper geen ondersteuning vir 'n nuwe pad bied nie. Die ou manier beteken om alles uit te grawe en te vervang met goeie vul, 'n proses wat jou begroting en jou skedule kan doodmaak.

Geocells reinforce weak subgrades by creating a three-dimensional confinement system. This honeycomb structure locks in aggregate, preventing it from moving sideways and creating a stiff, stable "mattress" that effectively bridges over the soft ground below.

The "Mattress Effect" Explained

The secret to the geocell system is 3D confinement. Dink aan wat gebeur wanneer 'n vragmotor oor los gruis op sagte grond ry. Die gruis stoot net na buite en af en skep 'n groef. Die geosel se sterk, onderling gekoppelde selwande keer dat dit gebeur. Wanneer 'n las toegepas word, verskaf die selwande spanning, wat die invulmateriaal in plek hou en dit dwing om as 'n enkele, soliede plaat op te tree.

I once worked with a contractor building a temporary access road in a swampy area for a mining operation. Their trucks were getting bogged down daily. Instead of replacing the soil, we recommended they lay down a separation geotextile and then expand geocell panels on top. By doing this, they were able to use locally sourced, lower-quality sand as infill. The geocells increased the bearing capacity of the soft ground by nearly three times. The result? Their trucks could drive smoothly without creating ruts, and they saved a fortune on not having to haul in expensive engineered stone. The system works by:

- Confining the Infill: The cell pockets prevent lateral spreading of the aggregate.

- Increasing Stiffness: Deur die aggregaat aanmekaar te sluit, skep die geoselstelsel 'n semi-rigiede plaat met 'n baie hoër styfheid as die aggregaat alleen.

- Verbetering van dravermoë: Hierdie stywe matras versprei die vrag oor 'n wyer area, sodat selfs baie swak grond (met 'n CBR minder as 3) swaar verkeer kan ondersteun.

Watter voordele bied geoselle in die verspreiding van vragte en die voorkoming van spore?

Jou nuwe grondpad lyk perfek totdat die eerste swaar reën en 'n paar gelaaide vragmotors daaroor ry. Nou is dit bedek met diep spore wat water hou, wat die hele oppervlak in 'n modderige gemors verander wat konstante gradering en herstel verg.

Geoselle versprei gekonsentreerde wielvragte oor 'n baie wyer area, wat die vertikale spanning op die ondergrond verminder. Dit keer dat die grond onder druk vervorm en verminder die vorming van spore aansienlik, wat die pad se funksionele lewensduur vir jare verleng.

Versprei die druk

Die wetenskap is eenvoudig maar ongelooflik effektief. 'n Enkele vragmotorband oefen geweldige druk op 'n baie klein area uit. Op 'n onversterkte pad slaan hierdie druk direk in die ondergrond in, wat veroorsaak dat dit vervorm. A geosel stelsel acts like a set of snowshoes, spreading that same weight over an area three to four times larger. This dramatically lowers the pressure at any single point on the weak soil below.

Because the pressure is so much lower, the subgrade doesn't shift or compact unevenly. The result is a massive reduction in rutting—studies show a decrease of up to 18%, depending on the design. This benefit is crucial for both unpaved and paved roads.

- Unpaved Roads: For haul roads or rural access roads, this means the surface stays level and usable without constant grading. You save on fuel, labor, and machinery costs.

- Paved Roads: For roads with an asphalt or concrete surface, preventing rutting in the base layer is even more critical. A stable base means the expensive pavement on top won't crack or settle, which is the main cause of potholes and surface failure.

How do geocell-reinforced roads compare to traditional road bases in durability and maintenance?

Building a traditional road means buying, trucking, and laying a thick layer of expensive, high-quality stone. Even then, it's prone to failure and seems to be under constant repair, consuming your annual maintenance budget with patching and resurfacing.

Geosel-versterkte paaie is aansienlik meer duursaam, en verleng onderhoudsintervalle van elke 5-7 jaar tot so lank as 12-15 jaar. Hulle bereik dit deur die vereiste aggregaatdikte te verminder en algemene foute soos spoorvorming te voorkom, wat tot groot langtermyn kostebesparings lei.

'n Slimmer belegging met 'n laer lewensikluskoste

While geocells may add a small amount to the initial construction cost, the return on investment is huge. When I talk to government procurement agents or EPC contractors, we don't just talk about the price per square meter; we talk about the total cost of ownership over 20-30 years.

A geocell system allows engineers to reduce the thickness of the base aggregate layer by 15-25% while achieving the same or better structural performance. That's an immediate, upfront saving on materials and transportation. But the real savings come later. Because the geocell base is so stable and resistant to deformation, the road lasts longer. The numbers are compelling, and this is how they typically break down for a project:

| Kenmerk | Traditional Road Base | Geocell-Reinforced Road Base |

|---|---|---|

| Base Thickness | Requires thick, high-quality aggregate | Reduces aggregate thickness by 15-25% |

| Material Quality | Needs expensive engineered stone | Can use lower-quality, local aggregate |

| Maintenance Cycle | Major repairs typically every 5–7 years | Extends maintenance to every 12–15 years |

| Lifecycle Cost | High due to frequent, costly repairs | Very low, with a cost-benefit ratio of 1.5 to 3 |

For every dollar you spend on a geocell system, you can expect to save up to three dollars over the life of the road by avoiding repairs, material replacement, and traffic downtime.

What factors should be considered when selecting and installing geocells for road stabilization?

You're convinced that geocells are the right solution for your project. But now you see different cell sizes, heights, and panel dimensions. Choosing wrong or installing poorly can compromise the entire system, wasting your investment.

Key factors for selecting geocells include the cell depth, cell opening size, and material seam strength, which must match the expected load and infill material. Proper installation requires a prepared subgrade, correct anchoring, and complete compaction of the infill.

Getting the Details Right

Getting the design and installation correct is straightforward if you focus on the fundamentals. I always guide my clients to consider these points:

Selection Factors:

- Cell Depth (Height): Deeper cells provide greater confinement. For very weak soils or very heavy loads, you'll need deeper cells (e.g., 150mm or 200mm). For firmer ground, a shallower cell (e.g., 100mm) may be sufficient.

- Cell Opening Size: The size of the cell pocket needs to be appropriate for your infill material. A good rule of thumb is that the largest stone in your aggregate should be no more than one-third the size of the cell's diagonal opening.

- Seam Strength: The geocell is only as strong as its welds. The ultrasonic welds that hold the strips together must be strong enough to withstand the stresses of infill and compaction. Always check the manufacturer's data sheet for seam peel strength.

Key Installation Steps:

- Prepare the Subgrade: Create a smooth, level surface. In very soft conditions, lay a nonwoven separation geotextile first.

- Anchor and Stretch: Securely anchor the end of the geocell panel and stretch it to the specified length and width. This is critical; under-stretching the panel results in loose cells and poor confinement.

- Fill the Cells: Fill the cells with your chosen aggregate, slightly overfilling them to account for compaction.

- Compact the Infill: Use a vibratory roller or plate compactor to compact the aggregate within the cells, which locks the entire system together.

Gevolgtrekking

Geocells create a mechanically stabilized road base that dramatically improves stability, reduces material needs, and slashes long-term maintenance costs. This makes them a superior investment for any road project on challenging ground, ensuring durability and a higher return over the project's life.