Choosing the wrong soil reinforcement can lead to rutting roads, eroding slopes, and catastrophic structural failure. These costly mistakes stem from a simple misunderstanding of how these products work.

Use geocells for their 3D cellular confinement to support heavy vertical loads on weak soils. Use geogrids for their 2D tensile strength to reinforce slopes and retaining walls. Your choice depends entirely on whether you need to confine soil or reinforce it.

This isn't a matter of one product being universally better; it's about selecting the right tool for the right engineering problem. A geocell used where a geogrid is needed (or vice versa) is an inefficient use of material and budget, and it may not provide the stability your project requires. Let's examine the core differences to ensure you make the right choice.

What are the key structural and functional differences between geocells and geogrids?

To an untrained eye, both products are just plastic grids for soil. This oversimplification leads to incorrect specifications and project designs that are doomed from the start.

Geocells are three-dimensional honeycomb structures that provide cellular confinement, acting like a mattress to distribute vertical loads. Geogrids are two-dimensional planar meshes that provide tensile reinforcement, acting like rebar to resist horizontal pulling forces.

The difference between 3D confinement en 2D reinforcement is the most critical concept to grasp. One creates a deep, rigid foundation, while the other adds strength within a soil layer. Their functions are fundamentally different and are not interchangeable.

| Kenmerk | Geocell | Geogrid |

|---|---|---|

| Struktuur | 3D Honeycomb Cells | 2D Planar Mesh |

| Mechanism | Confinement: Prevents lateral spreading of infill. | Reinforcement: Interlocks with soil to add tensile strength. |

| Primêre funksie | Distributes heavy vertical loads over weak subgrades. | Resists horizontal tensile forces in slopes & bases. |

| Resulting Action | Creates a stiff, semi-rigid foundation "mattress." | Increases the shear strength of the soil mass. |

How do I choose between a geocell and a geogrid based on my project’s soil type and load requirements?

Using the right product in the wrong application is a waste of money and a significant engineering risk. A geogrid won't stop a weak subgrade from sinking under a heavy load.

For weak, soft subgrades (CBR < 3%) under heavy vertical loads, choose geocells to improve bearing capacity and reduce rutting. For reinforcing slopes, embankments, or retaining walls against horizontal stress, choose geogrids for their superior tensile strength.

Your decision should be dictated by two simple questions: What is the primary load direction? And what is the quality of my subgrade?

Choose Geocells for:

- Heavy Vertical Load Support: Think unpaved access roads, storage yards, or foundation pads. The 3D cells distribute the wheel load over a much wider area, preventing it from punching into the weak soil below.

- Poor Subgrades: Geocells are exceptionally effective on soft, saturated soils. The confinement effect creates a stable base, often reducing the required thickness of expensive imported aggregate by 50% or more.

- Using Local Infill: Because the cells provide the confinement, you can often use cheaper, locally available sand or granular fill instead of importing expensive, high-quality aggregate.

Choose Geogrids for:

- Slope and Embankment Reinforcement: Geogrids are laid in horizontal layers within a soil slope to provide the tensile strength the soil lacks, preventing rotational failure.

- Keermure: Used in Mechanically Stabilized Earth (MSE) walls, geogrids act as tie-backs, connecting the wall facing to the soil mass behind it to resist lateral earth pressures.

- Base Reinforcement Over Firm Subgrades: On a moderately good subgrade, a geogrid can interlock with the base aggregate to prevent lateral movement, improving the stiffness of a paved road base.

What cost, installation, and maintenance factors should I compare when selecting geocell or geogrid solutions?

Focusing solely on the material price per square meter is a common mistake. The true cost includes infill material, labor, and the potential savings from reduced excavation and aggregate thickness.

Geogrids are typically cheaper and faster to install on large, flat areas. Geocells have a higher upfront material and labor cost but can significantly reduce the total project cost by allowing the use of cheaper local infill and reducing base layer thickness.

A smart buyer analyzes the total installed cost, not just the material quote. For some projects, the "more expensive" geocell can lead to substantial overall savings.

| Factor | Geocell | Geogrid |

|---|---|---|

| Material Cost | Higher per square meter. | Lower per square meter. |

| Installation Speed | Slower; requires expanding, staking, filling, and compacting. | Faster; simply unroll, anchor, and cover. |

| Labor Skill | More labor-intensive but generally low-skill. | Less labor-intensive. |

| Infill Material Cost | Major Advantage: Can use cheaper local sand or aggregate. | Requires higher-quality, well-graded aggregate for good interlock. |

| Total Project Savings | Reduces need for excavation and imported aggregate. | Less impact on reducing material thickness. |

How can I ensure long-term stability and performance when using geocells or geogrids in my project?

Relying on a single product for a complex problem can leave your project vulnerable. The most challenging sites often expose the limitations of using only one type of reinforcement.

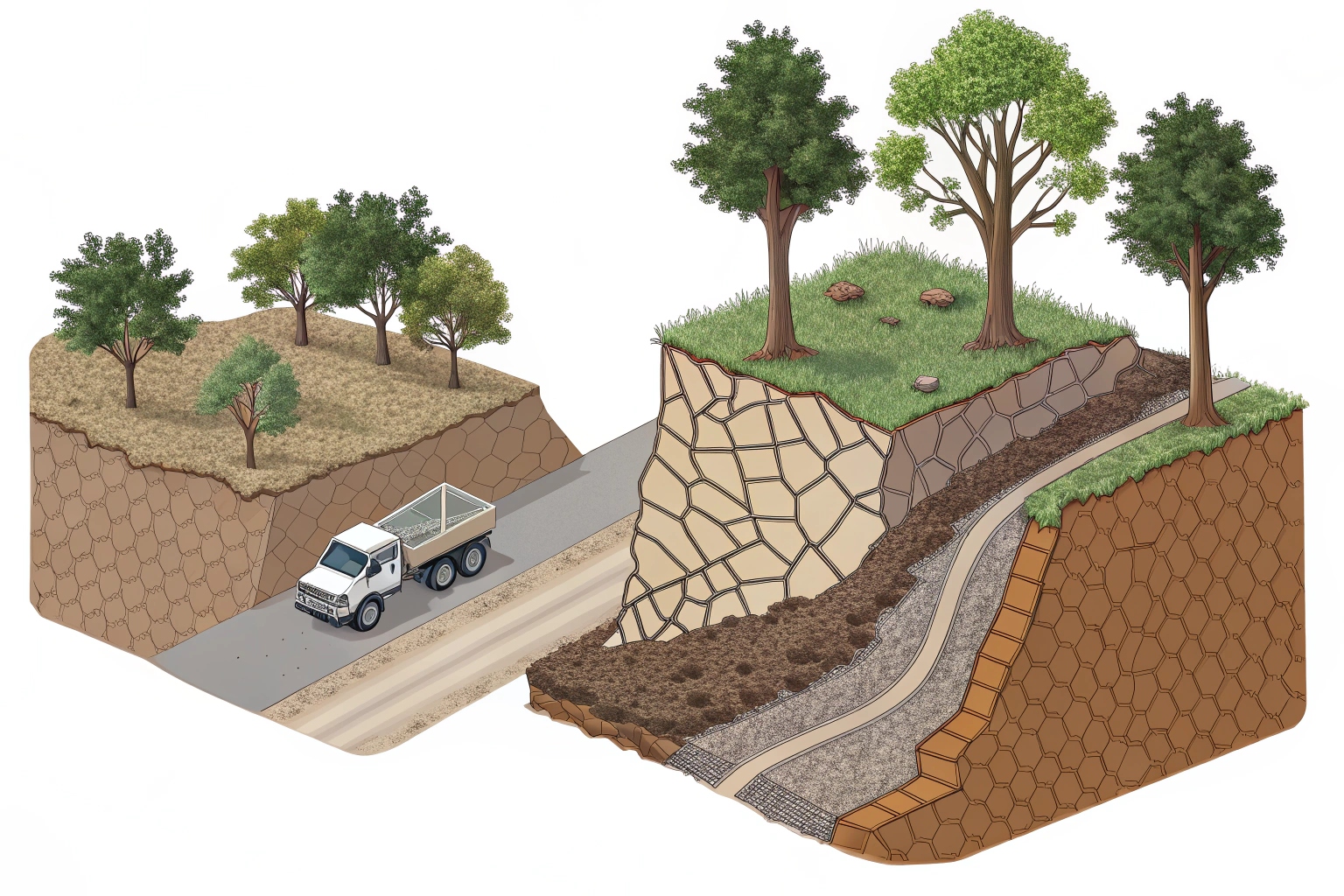

For maximum long-term stability in demanding applications, use a composite system. Combining a geocell base for confinement with an overlying geogrid for reinforcement leverages the distinct strengths of both products, creating a superior mechanically stabilized layer.

Why choose one when you can have the benefits of both? A composite system is the ultimate solution for ensuring performance on very soft soils or under very heavy loads.

Here’s how the synergy works:

- Geocell Base Layer: Installed directly on the soft subgrade, the geocell system creates a stiff "mattress" that distributes loads, prevents deep settlement, and confines the infill. This creates a solid working platform.

- Geogrid Reinforcement Layer: Placed on top of the geocell layer, within the base course aggregate, the geogrid locks the aggregate in place, providing high tensile strength to resist lateral spreading and rutting from traffic.

This combined approach provides both deep foundation support and planar reinforcement, creating a stabilized layer that is far more robust and durable than what either geocell or geogrid could achieve alone.

Gevolgtrekking

Geocells confine soil to support vertical loads, while geogrids reinforce it to resist tensile forces. For the most demanding projects, using them together in a composite system offers unmatched stability.