Heap leach pads are the economic engine of many modern mining operations, allowing for the profitable extraction of metals from low-grade ore. But this economic benefit comes with a significant environmental responsibility. The solutions used in heap leaching, often containing cyanide or acid, must be securely contained. A failure in the liner system can lead to catastrophic groundwater contamination, regulatory fines, and reputational damage.

This has fueled an ongoing industry debate: what is the appropriate level of containment? Is a robust single liner system sufficient, or is a double liner system with a leak detection layer truly necessary? The answer is not as simple as "more is always better." This guide will evaluate this critical question from an engineering, environmental, and risk-based perspective, providing a framework to help you decide which system is right for your project.

Overview of Heap Leach Pad Liner Systems

First, it is crucial to understand that these are engineered systems, not just layers of material. The performance of the entire system depends on how each component works together.

Single Liner Systems

A modern single liner system is far more than just a single sheet of plastic. It is a robust composite barrier designed for high performance. A typical configuration, from the bottom up, is:

- Compacted Subgrade: A smooth, stable foundation.

- Geosintetiese kleivoering (GCL): A thin layer of bentonite clay sandwiched between two geotextiles. It provides a self-healing, low-permeability hydraulic barrier.

- HDPE Geomembraan: A high-density polyethylene liner (typically 1.5mm to 2.5mm thick), which is the primary barrier to fluid flow. When placed directly on a GCL, it forms a "composite liner," where the GCL effectively seals any minor defects in the geomembrane.

- Protection Layer: A geotextile or select soil layer to protect the geomembrane from puncture by the sharp drainage aggregate above.

- Drainage Layer: A thick layer of coarse stone and a network of perforated pipes that collect the pregnant leach solution and transport it out of the pad by gravity.

This system is designed to provide a high level of containment by minimizing leakage through the composite barrier.

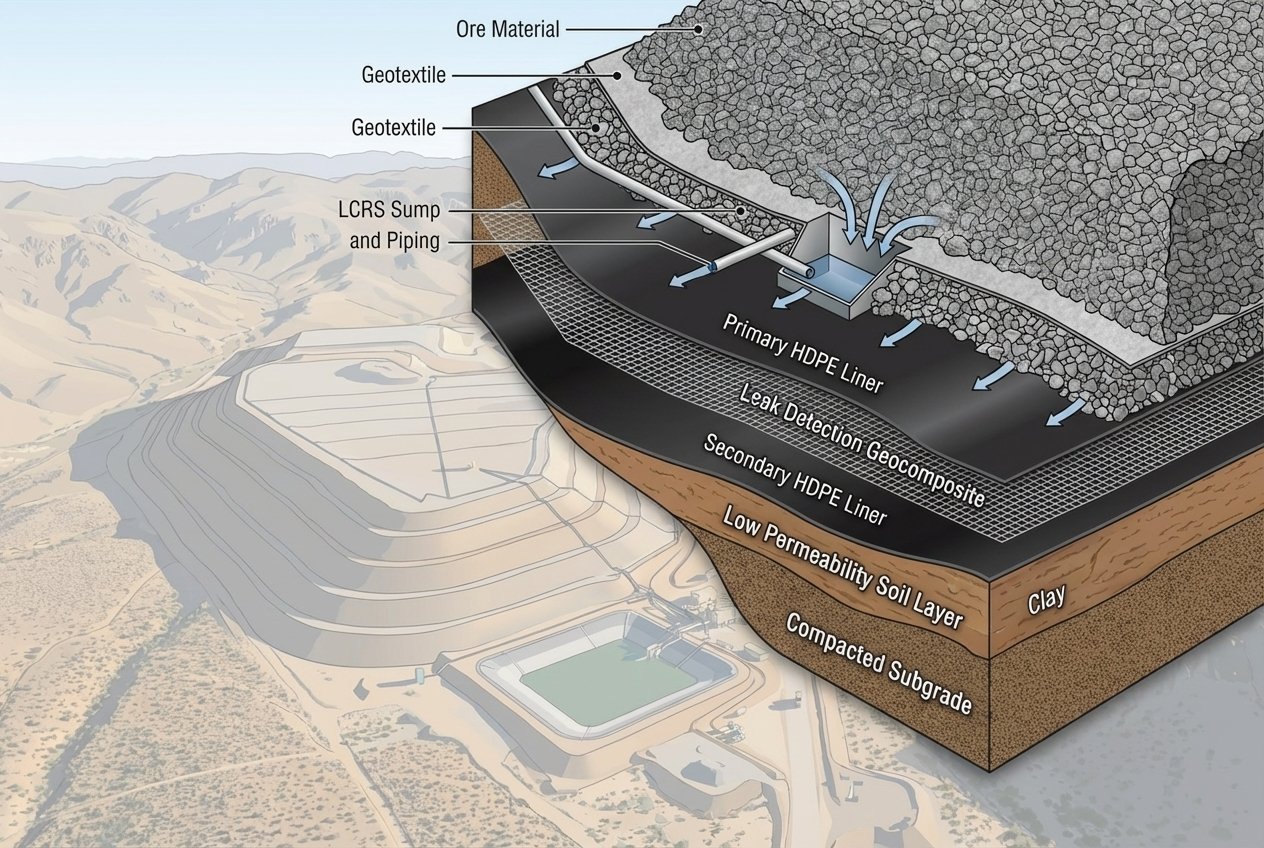

Double Liner Systems

A double liner system adds a layer of redundancy and, more importantly, a capability for leak detection and collection. The typical configuration includes:

- Compacted Subgrade

- Secondary Liner: The first HDPE geomembrane.

- Leak Collection and Removal System (LCRS): This is the key component. It's a drainage layer (often a geonet or gravel) designed to collect any fluid that leaks through the primary liner. This fluid is channeled to a sump where it can be detected and pumped out.

- Primary Liner: The second, upper HDPE geomembrane.

- Protection and Drainage Layers: As described in the single liner system.

The primary function of a double liner system is not just to provide a backup barrier, but to transform an uncontrolled leak into a managed condition. The LCRS allows operators to detect a leak, quantify its rate, and plan a response before the environment is compromised.

The Case for a Single Liner System

While a double liner sounds inherently safer, a well-designed single composite liner is often more than sufficient for the vast majority of heap leach pads. This is due to the fundamental operational differences between a heap leach pad and other containment facilities like landfills.

- They Are Fully Draining Systems: Heap leach pads are engineered to be highly permeable. The ore is coarse, and a massive drainage system is installed at the bottom. Leach solution percolates through the heap and is rapidly removed. This means the hydraulic head (the pressure of liquid on the liner) is extremely low, typically less than 0.6 meters (2 feet). Lower pressure means a vastly lower driving force for leakage.

- The Material is Geotechnically Stable: The heap is made of crushed, angular rock. This material has a high friction angle (typically 36-40°) and is very stable. It doesn't degrade or settle significantly over time like municipal solid waste. This stability means there is less stress and strain placed on the liner system, reducing the potential for long-term mechanical damage.

- Leaks are Manageable and Detectable: In the unlikely event of a leak in a single liner system, it is often detectable through careful operational monitoring. A significant leak would show up as an imbalance in the solution circuit (i.e., less pregnant solution being recovered than barren solution being applied). While remediation is expensive, it is often operationally and financially manageable for a mining company.

For a standard, flat, well-drained heap leach pad in a low-risk environment, a single composite liner provides a very high level of security. The additional cost of a double liner may not provide a proportional increase in safety.

The Case for a Double Liner System

A double liner system moves from being a "nice-to-have" to an "essential" feature under specific high-risk conditions. The decision to upgrade is justified when the potential consequences of a liner failure are unacceptably high.

- Valley-Fill Heap Leach Pads: When a heap is built in a natural valley, the pregnant solution can pool at the bottom of the heap before it is drained, creating a significant internal pond. The hydraulic head on the liner in these areas can be 10 meters or more. This high pressure dramatically increases the risk of leakage. In this scenario, a double liner with an LCRS is critical. It provides early warning of a primary liner breach, allowing for intervention before a major release occurs.

- Aggressive Leach Solutions or High-Value Ore: While cyanide is the standard, some processes use strong acids or other highly aggressive chemicals. The environmental consequence of releasing these solutions can be more severe, justifying the added protection of a double liner.

- Sensitive Environmental Settings: If a project is located over a critical aquifer, near a sensitive ecosystem, or close to local communities, the tolerance for any leakage is zero. A double liner provides a verifiable level of containment and monitoring capability that is essential for gaining regulatory and social license to operate.

- Extreme Stack Height or Seismic Zones: For exceptionally high heaps (>130 meters) or sites in high seismic zones, the added redundancy of a double liner can provide a necessary margin of safety against extreme geotechnical stresses.

In these cases, a double liner system is not over-design; it is prudent engineering to manage elevated risk.

Engineering and Economic Trade-Offs

The choice between a single and double liner system is a classic engineering trade-off between upfront capital cost and long-term risk management.

- Capital Cost: A double liner system can increase the initial cost of the liner system by 40-60%. For a large heap leach pad, this can amount to millions of dollars.

- Risk Analysis: A simple way to frame the decision is by considering the Expected Cost of a Leak, which is

(Probability of a Leak) x (Cost of Remediation).- For a standard, low-head pad, the probability of a significant leak from a well-built single liner is very low. The expected cost is therefore manageable. The high upfront cost of a double liner is difficult to justify financially.

- For a high-head valley-fill pad, the probability of a leak is significantly higher. The cost of remediation (especially potential groundwater contamination) is astronomical. The expected cost is therefore very high, making the investment in a double liner a clear and sensible business decision.

The goal is not to eliminate all costs, but to invest in a level of protection that is appropriate for the level of risk.

Common Misconceptions

There are several persistent misconceptions in the single vs. double liner debate that need clarification:

- Myth: "Two layers of HDPE are a double liner." Fact: No. A double liner system is defined by the presence of a Leak Collection and Removal System (LCRS) between the two liners. Without an LCRS, you simply have two layers of plastic with no way to detect or manage a leak.

- Myth: "Increasing the thickness of a single geomembrane is equivalent to a double liner." Fact: A thicker liner offers more puncture resistance, but it does not provide redundancy or leak detection. It remains a single point of potential failure.

- Myth: "A GCL under an HDPE geomembrane is a double liner system." Fact: This is a single composite liner. While highly effective, it is still considered one system. The GCL's primary role is to seal small imperfections in the primary HDPE liner, not to act as an independent, monitorable secondary barrier.

Conclusion: A Risk-Based, Site-Specific Decision

So, is a double liner really necessary? The answer is a definitive it depends. There is no universal "right" choice.

- For the majority of standard, free-draining heap leach pads, a well-designed and impeccably constructed single composite liner system provides more than adequate environmental protection and is the most economically sound choice.

- For high-risk projects—particularly valley-fills, sites over sensitive groundwater, or those with extreme operational parameters—a double liner system is not just justified; it is essential for responsible risk management.

The decision should not be based on a default assumption that "two is better than one." It must be the result of a rigorous, site-specific risk assessment conducted with sound engineering judgment. Choosing the right liner system is about balancing cost, constructability, and, most importantly, the long-term stewardship of the environment in which we operate.