Woven Geotextile — Manufacturer, Properties &Engineering Applications

High-strength polypropylene and polyester woven geotextile fabrics for road, slope, and drainage reinforcement. Factory-direct supply from China manufacturer with certified quality.

Export Global

Factory Directly

Certified Quality

Excellent Properties of Woven Geotextile

Woven geotextile provides high tensile strength with minimal elongation, ensuring excellent soil reinforcement and load distribution.

PP woven fabric offers stable strength under repeated loads, while PET filament fabric provides long-term creep resistance for permanent structures.

The interlaced yarn structure gives woven geotextile exceptional dimensional stability. It maintains its shape under heavy compaction or dynamic loading, making it ideal for road subgrade and embankment applications.

Woven geotextile effectively separates different soil layers while allowing controlled water flow through its uniform pore openings.

This prevents soil migration and maintains long-term drainage function in roads, railways, and retaining walls.

Made from chemically inert polypropylene (PP) or polyester (PET), woven geotextiles resist acid, alkali, and microbial degradation.

They maintain mechanical performance even in contaminated or saline soils.

For exposed or near-surface applications, woven geotextiles with UV-stabilized additives resist sunlight, oxidation, and temperature fluctuations.

PET woven types perform better under prolonged heat and ultraviolet exposure.

Though woven fabrics are denser than nonwoven ones, their designed pore size (AOS) allows controlled permeability, balancing filtration and drainage in engineering layers.

Flexible yet strong, woven geotextiles conform to irregular ground surfaces, resist puncture, and remain stable under soil pressure—ideal for uneven terrain or weak subgrades.

Both PP and PET woven geotextiles are recyclable, non-toxic, and designed for long-term soil stabilization with minimal environmental impact.

Get to Know Woven Geotextile Fabric

Woven geotextile is a synthetic fabric made by interlacing polypropylene (PP) or polyester (PET) yarns. It provides separation, reinforcement, and filtration in roads, slopes, and drainage systems.

It is mainly used for soil stabilization, base reinforcement, embankment construction, erosion control, and filtration in civil engineering and infrastructure projects.

Common types include:

Filament Woven Geotextile (PET or PP Long-Filament) – Made from continuous polyester or polypropylene filaments. It features very high tensile strength and low elongation, ideal for long-term reinforcement in slopes, retaining walls, and embankments.

Split Yarn Woven Geotextile (PP Tape Yarn) – Produced by weaving polypropylene split-film tapes. It is cost-effective and mainly used for road base separation, stabilization, and subgrade reinforcement.

Monofilament Woven Geotextile (PP Monofilament) – Made from single polypropylene filaments with uniform pore openings, offering excellent permeability and filtration for drainage, erosion control, and riverbank protection.

Yes. HDPE geomembrane has an extremely low permeability coefficient, making it fully waterproof for ponds, reservoirs, and leachate control in landfills and mining facilities.

Yes. Woven geotextiles allow controlled water flow through their designed pores (AOS = 0.1–0.6 mm). They are permeable but less so than nonwoven fabrics, balancing separation and filtration.

With proper soil cover, woven geotextiles can last over 50 years due to excellent chemical and UV resistance, especially PET long-filament types.

Types & Material options of Woven Geotextile

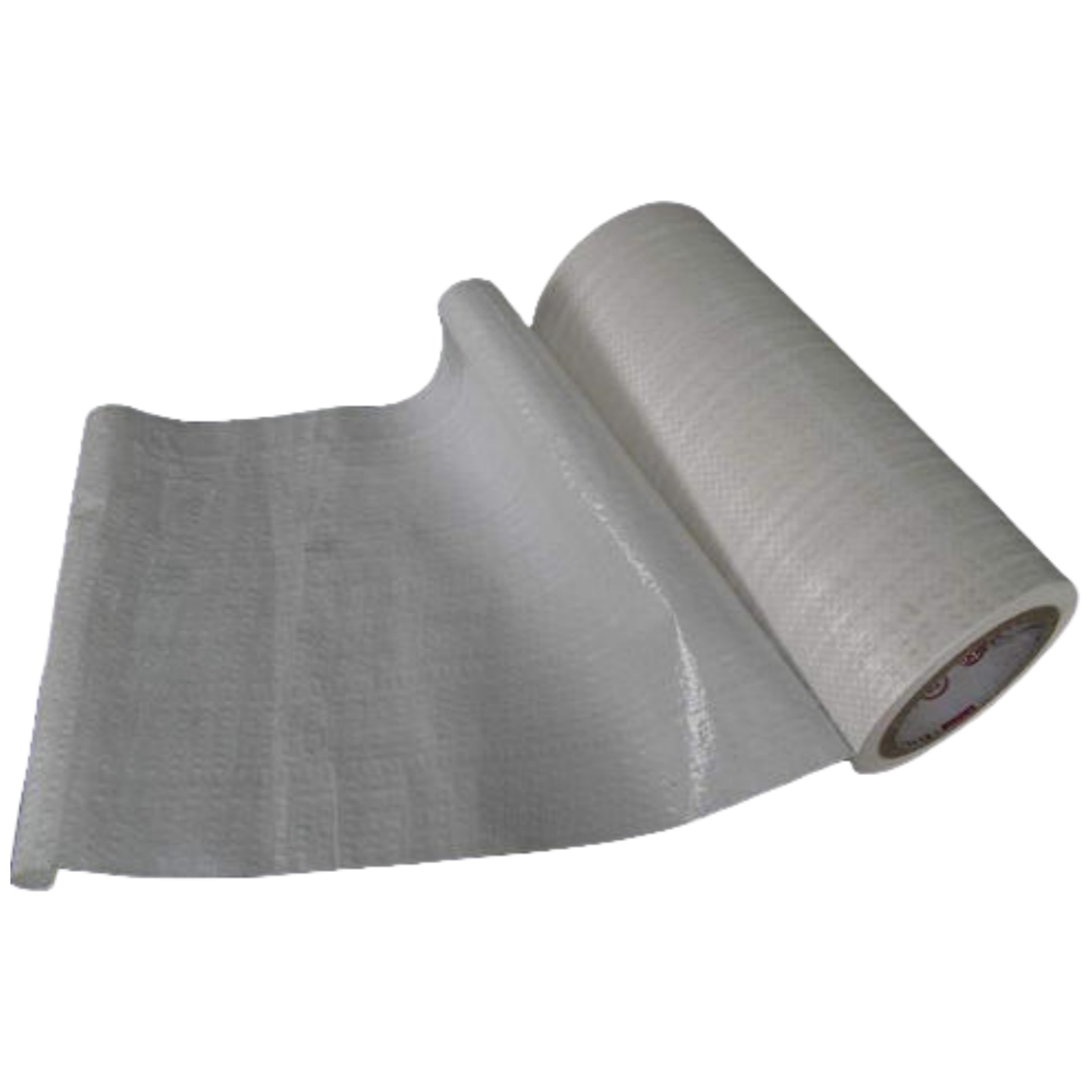

Description:

PP split-yarn woven geotextile (also called PP flat yarn woven fabric) is woven from parallel

polypropylene tape yarns in warp and weft. The compact plain-weave structure provides

high tensile strength, low elongation, and excellent layer separation,

making it the mainstream choice for road base reinforcement, railway subgrade, and

ground stabilization. It balances durability and economy for large-scale infrastructure.

Key Properties:

- High tensile strength (warp > weft) with low elongation

- Stable plain-weave; good load distribution and dimensional stability

- Effective separation of soil and aggregate layers; reduces rutting

- Controlled permeability; retains fines while allowing water to pass

- Lightweight, durable, easy handling; cost-effective for mass projects

Functions & Applications:

- Reinforcement & stabilization for road/rail subgrades and yards

- Separation between subgrade and base to prevent intermixing

- Filtration & drainage in embankments and platforms

- Used in highways, railways, airports, industrial pads, logistics yards

- Coastal revetment and erosion control with cushion layers

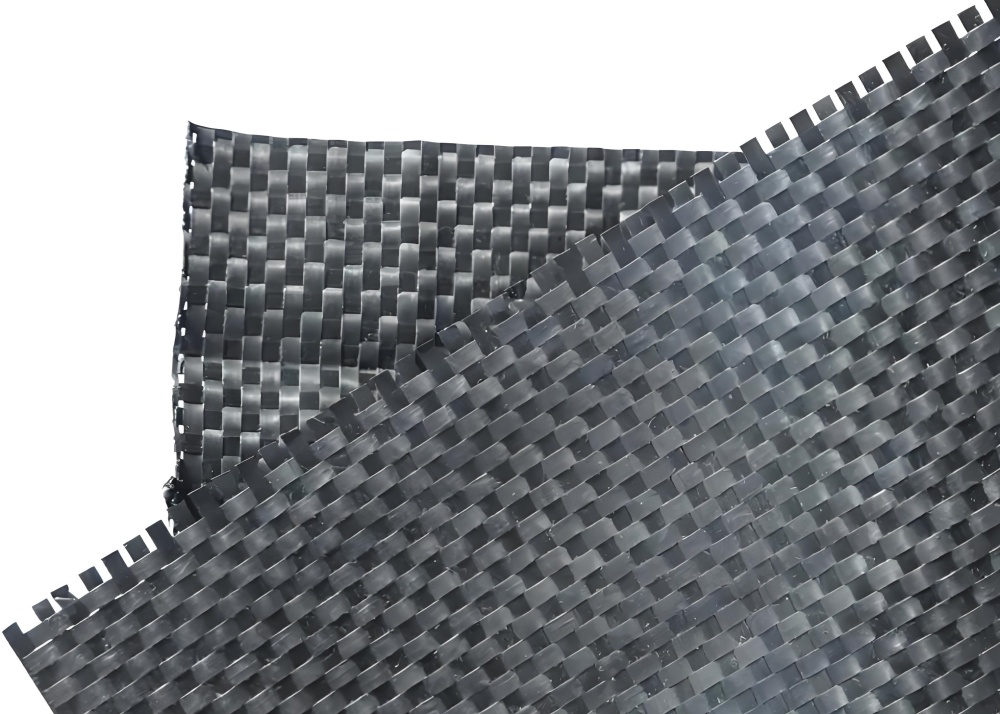

Description:

Filament woven geotextile is produced on wide shuttleless looms using continuous PET or PP long filaments.

It provides very high tensile modulus, low creep, and long-term durability,

critical for slope reinforcement, retaining walls, embankments,

and soft-ground improvement. With engineered pore openings, it delivers separation and filtration while

maintaining structural integrity in permanent works.

Key Properties:

- Very high strength & modulus; excellent dimensional stability

- Low creep for long-service geotechnical structures

- Chemical & UV resistance (ASTM/ISO compliant)

- Controlled permeability; soil retention with steady flow

- Efficient logistics: light rolls, easy installation

Functions & Applications:

- Reinforcement of slopes, retaining walls, levees, and dams

- Separation and stabilization for soft foundations

- Filtration & protection under geomembranes and liners

- Used in embankments, dikes, ports, bridges, airports

- Suitable for permanent civil & geotechnical projects

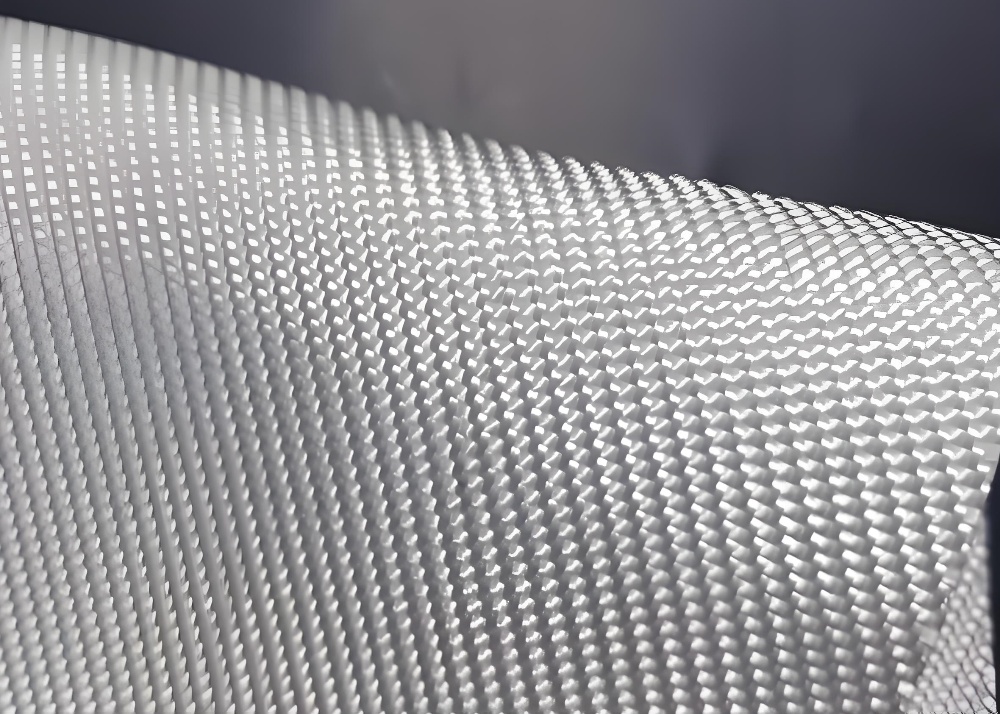

Description:

Monofilament woven geotextile is woven from smooth single PP filaments, creating

uniform pore openings that provide high permeability and anti-clogging performance.

It combines tensile capacity with superior filtration, making it the preferred woven option for

hydraulic engineering, riverbank/coastal protection, and drainage layers where

long-term water flow is essential.

Key Properties:

- High permeability with reliable soil retention

- Clogging resistance against silt and biofilm build-up

- Good tensile strength; stable under compaction

- UV & chemical resistance in fresh or sea water

- Long service life under soil cover

Functions & Applications:

- Filtration & drainage for rivers, lakes, and reservoirs

- Erosion control on revetments, shorelines, and slopes

- Separation with drainage in hydraulic & harbor works

- Aquaculture ponds and environmental water control

- Protective buffer under coastal armor systems

Customization options of Woven ceotextile

| Product Type | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | Roll Width (m) | Application Range |

|---|---|---|---|---|

| Woven Geotextile — Split Yarn | 20–80 kN/m(15-56KN/M) | 75–400 g/m² (≈ 2.2–11.8 oz/yd²) | 1.0–6.0 m | Used for road base separation, subgrade stabilization, and ground improvement |

| Woven Geotextile — Filament | 35–250 kN/m | 300–950 g/m² (≈ 8.8–28 oz/yd²) | 1.0–6.0 m | For slopes, retaining walls, embankments, and long-term reinforcement |

| Woven Geotextile — Monofilament | 100–200 kN/m | 250–600 g/m² (≈ 7.4–17.7 oz/yd²) | 1.0–6.0 m | For filtration, drainage layers, and hydraulic protection works |

Typical Applications of Woven ceotextile

| Project Scenario | Recommended Product Type | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | AOS (mm) | Roll Width (m) | Remarks / Key Benefit |

|---|---|---|---|---|---|---|

| Road base separation & stabilization (highways, yards) |

Split Yarn PP | 40–80 kN/m | 200–300 g/m² (≈ 5.9–8.8 oz/yd²) | 0.20–0.40 | 3.9–5.2 | High tensile with low cost; prevents intermixing and rutting |

| Soft ground or low CBR < 3% (embankments, platforms) |

Filament PET/PP | 100–150 kN/m | 250–400 g/m² (≈ 7.4–11.8 oz/yd²) | 0.15–0.30 | 4.0–6.0 | High modulus & low creep; improves long-term settlement control |

| Slopes & retaining walls (permanent reinforcement) |

Filament PET | 120–200 kN/m | 400–950 g/m² (≈ 11.8–28 oz/yd²) | 0.15–0.25 | 4.0–6.0 | Superior long-term stability under sustained load |

| Drainage & filtration layers (ditches, French drains, filter layers) |

Monofilament PP | 60–120 kN/m | 250–600 g/m² (≈ 7.4–17.7 oz/yd²) | 0.30–0.60 | 3.9–5.2 | Uniform pore openings; high permeability and anti-clogging |

| Riverbank / coastal protection (revetments, drainage, filtration) |

Monofilament PP | 80–120 kN/m | 350–600 g/m² (≈ 10.3–17.7 oz/yd²) | 0.35–0.60 | 3.9–5.2 | High flow rate; excellent durability in hydraulic environments |

Woven Geotextile Testing Standards & Performance Data Sheet

| Property | Test Method (ref.) | Typical Range / Requirement | Notes (for Split Yarn / Filament / Monofilament) |

|---|---|---|---|

| Tensile Strength (MD / CD) | ASTM D4595 / ISO 10319 | 40–250 kN/m | Split Yarn PP: medium strength and cost-effective; Filament PET/PP: high modulus and low creep; Monofilament PP: moderate strength with good permeability. |

| Elongation at Break | ASTM D4595 | ≤ 25% (PP) · ≤ 20% (PET) | PP types (Split/Mono) have slightly higher elongation; PET Filament provides better dimensional stability. |

| Tear Strength | ASTM D4533 | 200–800 N | Resistance to tearing and edge damage; increases with fabric density and weight. |

| CBR Puncture Strength | ASTM D6241 | 1.5–8.0 kN | Higher CBR values are recommended for heavy-duty or coarse aggregate applications. |

| Apparent Opening Size (AOS) | ASTM D4751 | 0.15–0.60 mm | Monofilament: 0.30–0.60 mm for drainage and anti-clogging; Filament: 0.15–0.30 mm for fine filtration. |

| Permittivity / Water Flow | ASTM D4491 | 0.05–0.50 s⁻¹ | Monofilament has higher permeability; Filament types have lower flow for filtration control. |

| Mass per Unit Area | ASTM D5261 | 75–950 g/m² (≈ 2.2–28 oz/yd²) | Lightweight fabrics for separation; heavyweight fabrics for reinforcement and hydraulic works. |

| UV Resistance (retained strength) | ASTM D4355 (500 h) | ≥ 70% retained | UV-stabilized grades are recommended for exposed or shallow-covered installations. |

| Seam Strength | ASTM D4884 | ≥ 60% of fabric tensile | Seamed or stitched joints should maintain at least 60% of the parent fabric tensile strength. |

| Thickness (optional) | ASTM D5199 | 0.3–2.0 mm | Optional reference; thickness correlates with unit weight and tensile capacity. |

Woven Geotextile Installation & Quality Control (CQA)

Laying Methods

Surface Preparation:

Ensure the subgrade is smooth, compacted, and free of sharp stones or debris that may puncture the fabric. Remove any standing water before installation.Unrolling & Alignment:

Woven geotextiles are supplied in rolls and should be unrolled manually or by light machinery along the prepared surface, avoiding tension or stretching.Overlap Width:

Typical overlaps are 300–450 mm for unstitched joints. In areas requiring high load or filtration control, seams can be joined by sewing or heat-bonding depending on project specifications.Anchoring & Fixation:

Secure the fabric temporarily with sandbags, U-shaped pins, or anchor trenches to prevent wind uplift and misalignment during placement of fill materials.Backfilling & Protection:

Place soil, aggregate, or sand carefully in layers to avoid fabric displacement. Avoid dropping materials from excessive height. Maintain uniform tension and avoid wrinkles.Connection with Other Layers:

When combined with geomembranes, drainage nets, or erosion mats, the woven geotextile should be placed beneath or above according to its function (separation, filtration, or reinforcement).

CQA Recommendations

Visual inspection before and after installation to detect damage or folds.

Overlaps and joints should comply with project specifications and test results.

Field sampling and tensile testing may be performed to verify material conformity.

Damaged areas must be cut and patched with fabric extending at least 0.3 m beyond the defect.

Why Choose WP Specialist?

Over the years, WP Specialist has built a strong reputation as one of China’s trusted woven geotextile manufacturers and global suppliers of geosynthetic materials.

We focus on delivering reliable woven fabrics that meet the demanding needs of civil, road, and hydraulic engineering projects worldwide.

Our woven geotextiles combine high tensile strength, stability, and consistent quality — backed by factory-direct service and technical expertise.

- Free Samples of Woven Geotextile Fabric

- Expert Project Support

- Reliable Quality Assurance

- Over 10 Years of Manufacturing Experience

- Factory Direct Supply

Ready to Specify a Geotextile?

- 15+ Years of Factory-Direct Expertise

- Custom-Engineered Solutions for Your Needs

- Global Shipping & Logistics Support

- A Transparent, No-Obligation Quote

- 100% Confdentiality Guaranteed

Your email information will be kept strictly confdential and our business staff will ensurethat your private information is absolutely safe!

Contact

- info@waterproofspecialist.com

Reply within 12 hours!

Please pay attention to the email with the suffix “@waterproofspecialist.com”.