A single sharp rock or dropped tool can puncture your expensive geomembrane liner, leading to catastrophic failure. Protecting this critical barrier is essential, but how can you ensure its safety during and after construction?

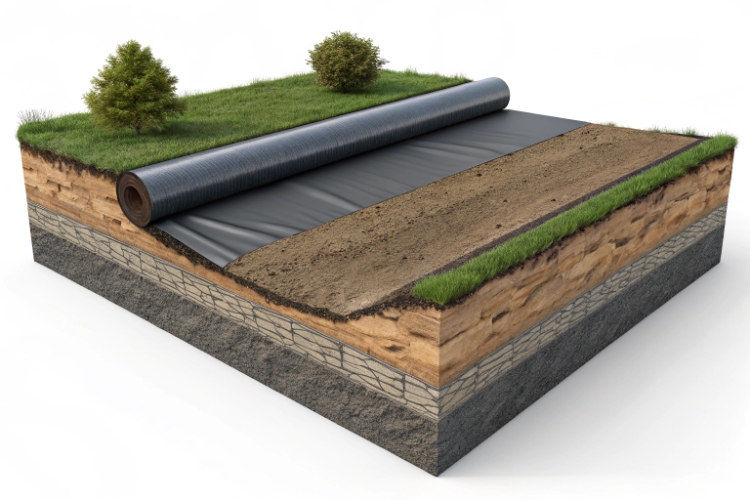

A nonwoven geotextile protects liners by acting as a thick, durable cushion. It absorbs and dissipates the force from sharp objects and friction, preventing punctures and surface wear that could compromise the integrity of the underlying geomembrane.

From my experience exporting geosynthetics, I can tell you that a staggering 60-80% of geomembrane damage happens during the installation phase. It’s a huge risk. That’s why I always tell my clients that a protection geotextile isn't an optional add-on; it's a fundamental part of a secure containment system. Let's look at exactly how this simple fabric provides such powerful protection.

How does geotextile act as a cushioning layer to reduce puncture risk?

You know that a geotextile can stop a sharp rock, but how? It seems too simple. Understanding the mechanics helps you appreciate why a thicker, heavier fabric is your best defense against liner failure.

A thick nonwoven geotextile acts like a sponge for force. Its three-dimensional fiber structure absorbs impact energy from sharp points, distributing the stress over a much larger area and preventing the force from concentrating on and puncturing the liner.

When a client asks me about puncture protection, I always emphasize that it's a game of physics, not just raw strength. The goal is to stop the pressure from building up at a single point.

The Power of Thickness

The single most important factor for puncture protection is the geotextile’s mass, or weight (measured in grams per square meter, gsm). A heavier geotextile (e.g., 400 gsm vs. 200 gsm) is thicker. This thickness creates a physical buffer zone. When a sharp stone presses down, it has to push through more material, and the fibers have more room to move and absorb the load. While tensile strength is important for other applications, for pure puncture protection, a thick, heavy fabric will always outperform a thin, high-strength one.

The Importance of Structure

Needle-punched nonwoven geotextiles are made of countless polypropylene fibers interlocked in a random, 3D web. This structure is key. Instead of a single point taking all the force, the load is shared across thousands of fibers. This spreads the stress out, reducing the pressure at any one point on the geomembrane below to a safe level. This mechanism also limits the strain on the geomembrane itself, keeping it below 6%, which helps prevent long-term stress cracking.

How does geotextile prevent abrasion damage during installation and long-term use?

A puncture isn't the only threat to your liner. Constant rubbing and friction from gravel or equipment traffic can wear down the geomembrane surface over time, leading to leaks. How does a soft fabric prevent this grinding damage?

Geotextile acts as a sacrificial layer that absorbs all the frictional wear. Its fibrous surface endures the rubbing and scraping, preventing direct contact between abrasive materials (like gravel) and the smooth surface of the geomembrane liner.

I tell my clients to think of it like the screen protector on your phone. The protector gets scratched, but your expensive screen remains perfect underneath. The geotextile performs the exact same function in a containment system.

The protection works in two ways. First, the geotextile's surface takes the direct hit from any sliding or shifting materials, like when a contractor places and compacts a gravel drainage layer. The fabric fibers are designed to withstand this wear. Second, and more importantly, it creates a permanent separation. The abrasive gravel and the smooth geomembrane never touch. This is crucial for long-term performance. In applications with dynamic loads, like a road or a landfill cap, repeated traffic can cause materials to shift and grind. The geotextile continuously absorbs this movement, preventing the slow but steady degradation of the geomembrane surface that would otherwise occur over years of service. Without this sacrificial layer, the liner's lifespan would be significantly reduced.

In what types of projects is geotextile commonly used as a protective layer?

You know that geotextile offers protection, but where is it absolutely essential? Deploying it in the right application ensures you get maximum value and security, avoiding failures in high-stress environments.

Geotextiles are essential for protecting liners in landfills, reservoirs, and canals. They are also critical under rip-rap for erosion control, beneath roads and railways, and on steep slopes where materials are likely to shift and cause damage.

In my experience, almost any project that involves a geomembrane benefits from a protection geotextile. The cost is marginal compared to the risk of a leak. Here are the most common scenarios where I see them specified:

| Project Type | Why Geotextile is Critical |

|---|---|

| Landfill Liners | Protects the primary HDPE geomembrane from being punctured by the gravel drainage layer or sharp objects in the waste. |

| Reservoirs & Canals | Provides a cushion between the liner and the subgrade soil or a protective rock/concrete cover. |

| Coastal & Защита берега реки | Placed under heavy armor stone (rip-rap) to prevent the sharp edges of the rocks from tearing the underlying filter fabric or soil. |

| Tunnels & Foundations | Shields waterproofing membranes from damage during backfilling with angular stone. |

| Heap Leach Pads | Protects the geomembrane liner from being punctured by the sharp ore being placed on top. |

A few years ago, a client building a major reservoir in a rocky region tried to save money by omitting the protection geotextile. During backfilling, their liner was punctured in multiple places. The cost of finding and repairing the leaks was ten times what the geotextile would have cost in the first place.

How can I choose the right geotextile strength and thickness for effective protection?

Choosing the wrong geotextile can give you a false sense of security. A fabric that's too light won't provide adequate cushioning, while over-specifying is a waste of money. How do you find the right balance for your project?

Choose the right geotextile by matching its mass per unit area (gsm) and static puncture resistance (CBR) to the size and sharpness of the overlying material. Heavier, thicker geotextiles (higher gsm) are required for larger, more angular rock.

When a client asks for a recommendation, I don't give them one single answer. Instead, I ask them about their site conditions. The choice is a technical decision based on risk. Here are the factors we discuss:

Key Performance Properties

To make an informed choice, you need to look at the manufacturer's data sheet for a few key values. Don't just look at the product name; look at the numbers.

- Mass Per Unit Area (g/m² or oz/yd²): This is the most important indicator of thickness and cushioning ability. A heavier fabric provides more protection. A value of 400 gsm is common for moderate protection, while 800+ gsm might be needed for sharp, heavy rock.

- Static Puncture Resistance (ASTM D6241): This test measures the force required to push a plunger through the fabric. A higher value means better resistance to puncture from blunt objects.

- Cone Drop Puncture Resistance (ASTM D5494): This measures how well the fabric resists impact from a falling, sharp object, simulating a dropped rock.

For a small investment of $0.50–$1.50 per square meter, a protection geotextile insures a geomembrane that costs $2–$5 per square meter to install. It's the best insurance policy you can buy for your project.

Заключение

A nonwoven geotextile is an inexpensive but essential insurance policy for any liner system. Its ability to cushion against puncture and resist abrasion is the key to ensuring the long-term integrity of your critical containment project.