Landfill gas is a powerful, unavoidable byproduct of waste decomposition. If left uncontrolled, this methane-rich gas can build pressure beneath the final cap, causing liner "whales" or bubbles, compromising slope stability, and creating uncontrolled emission points. Simply put, managing this gas is not optional; it's a critical safety and environmental requirement.

The solution is an engineered gas venting layer, a dedicated pathway designed to safely collect and transport gas to vents. This guide explains why the modern geocomposite—a geonet core bonded with geotextile layers—is not just an alternative to traditional gravel layers, but a technically superior solution for landfill closure design.

Let's start by understanding the fundamental role this layer plays.

Understanding the Function of Gas Venting Layers in Landfills

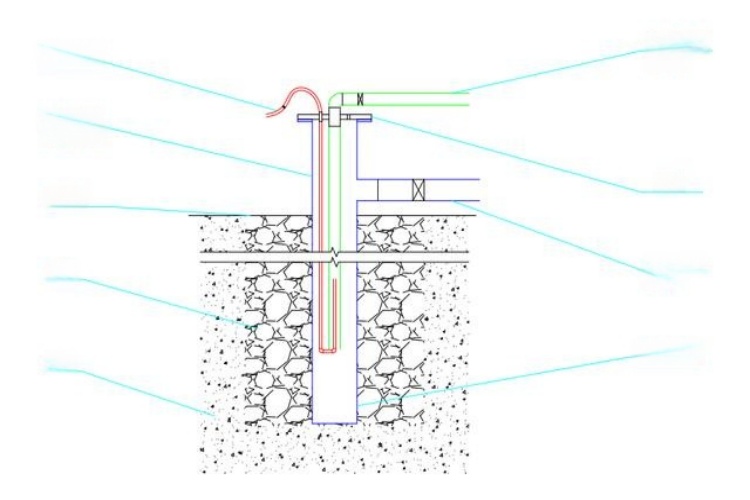

The gas venting layer is a critical component of the landfill's final cover system. Its primary function is to create a high-permeability void space directly beneath the impermeable geomembrane cap. This allows landfill gas, which naturally moves upwards, to be intercepted and channeled horizontally towards collection pipes or vents instead of building up pressure. This single function is crucial for maintaining the long-term integrity of the entire capping system.

How Geonets Provide High-Flow Gas Transmission Capacity

The core of a modern gas venting system is the geonet. This is a three-dimensional polymer structure made of intersecting ribs that create a high-volume void space. Its performance in gas venting is defined by two key properties:

- High In-Plane Flow: Unlike soil or gravel, a geonet is engineered specifically for lateral transmission. Its open, continuous channels offer minimal resistance to gas flow, allowing large volumes of gas to move quickly across wide areas. High-performance, tri-planar geonets provide even greater flow capacity than standard bi-planar products.

- Resistance to Compression: A gas venting layer must maintain its void space under the immense weight of the overlying soil cover (which can be 300 mm thick or more). Geonets are made from high-density polyethylene (HDPE), which is crush-resistant and maintains its structure under high compressive loads, ensuring the flow path remains open for decades.

Why Adding Geotextile Enhances Gas Venting Efficiency

While a geonet provides the flow path, it cannot function reliably on its own. It requires a non-woven geotextile laminated to one or both sides to create a complete geocomposite. The geotextile performs two essential functions:

- Фильтрация: The top geotextile layer acts as a filter, preventing fine soil particles from the overlying cover from washing into and clogging the geonet's channels. Without this filter, the geonet would quickly lose its flow capacity.

- Защита: The bottom geotextile layer serves as a cushion, protecting the underlying geomembrane from potential abrasion or puncture by the stiff geonet ribs.

A typical specification for the geotextile in these composites is a non-woven fabric with a weight of 200 g/m² or more, ensuring both effective filtration and adequate protection.

Performance Advantages of Geonet–Geotextile Composites

When combined, a geonet and geotextile create a high-performance system with significant advantages for long-term landfill performance.

- Drastically Reduced Clogging Risk: The engineered structure of a geonet is far less susceptible to biological clogging (bio-fouling) than the porous surface of gravel. The smooth HDPE ribs make it difficult for microbial biofilms to form continuous, flow-blocking masses.

- Reliable Long-Term Transmissivity: Studies show that while all drainage materials experience some reduction in flow over time, geocomposites maintain their performance exceptionally well. It's common for a geocomposite to retain over 70% of its initial flow capacity after 20 years, whereas gravel layers can lose 50-90% due to clogging.

- Durability and Chemical Resistance: Made from HDPE, these composites are chemically inert and will not react with leachate or other materials in the landfill. They are also flexible and can withstand the differential settlement that occurs as waste decomposes.

Comparison with Traditional Gravel Gas Venting Layers

For decades, the standard for gas venting was a thick layer of gravel or crushed stone. While inexpensive as a raw material, it has significant engineering and logistical drawbacks compared to a geocomposite.

| Особенность | Traditional Gravel Layer | Geonet-Geotextile Composite |

|---|---|---|

| Typical Thickness | 300 mm | 10–15 mm |

| Airspace Savings | Consumes valuable landfill airspace | Saves over 95% of the vertical space, maximizing capacity |

| Weight & Logistics | Extremely heavy; requires massive quarrying & transport | Lightweight and delivered in rolls; easy to handle |

| Clogging Risk | High risk of biological and fine particle clogging | Low risk; engineered for stable long-term flow |

| Установка | Slow, labor-intensive, heavy equipment required | Fast and simple; can be rolled out by a small crew |

| Performance Consistency | Highly variable depending on stone quality and placement | Factory-manufactured for consistent, reliable performance |

Design Considerations for Using Geocomposite Gas Venting Layers

While geocomposites are superior, they must be designed and installed correctly.

Calculating Required Flow Capacity (Transmissivity)

The key design parameter is transmissivity (θ), which measures the in-plane flow rate. The required transmissivity must be greater than the expected gas generation rate. A simplified formula is:

θ_required = (Gas Generation Rate) / (Slope Gradient × Slope Length)

For a typical landfill, the required long-term transmissivity is often in the range of 2 x 10⁻⁵ m²/s. A standard geocomposite can provide an initial transmissivity of 0.3 x 10⁻³ m²/s or higher. However, the design must account for long-term performance reduction.

- Geocomposite Reduction Factor: Assume it will retain ~70–90% of its initial flow.

- Gravel Reduction Factor: Must assume it will only retain ~30–50% of its initial flow.

This means a gravel layer needs a much higher initial transmissivity (and thus greater thickness or higher quality material) to meet the same long-term design requirement.

Case Scenarios Where Geonet + Geotextile Performs Best

While suitable for nearly all landfill closures, geocomposites are the only practical choice in several common scenarios:

- Steep Slopes: Gravel is heavy and can be unstable on steep slopes, increasing the risk of sloughing and cover failure. Lightweight geocomposites are far more stable.

- Limited Airspace: When maximizing landfill capacity is a priority, saving 250-300 mm of vertical height across the entire final cover represents a massive financial value.

- High Overburden Pressure: In deep landfills, the weight of the final cover is immense. Geonets are specifically designed to maintain flow under these high loads, where gravel may crush or consolidate.

- Remote or Difficult Sites: Transporting thousands of tons of quality gravel to a remote site is often logistically and financially unfeasible. Shipping lightweight rolls of geocomposite is far more efficient.

Conclusion:

While traditional gravel layers can work, they represent an outdated approach laden with risks of clogging, inconsistent performance, and logistical challenges. The geonet–geotextile composite is a precisely engineered solution that offers higher long-term reliability, superior flow capacity under load, and significant construction advantages. For modern landfill design, it saves valuable airspace, reduces construction costs, and provides a more dependable system for safely managing landfill gas for the entire post-closure period.