Choosing the wrong geotextile fabric can cause project failure. Using a material that clogs or lacks strength wastes money and compromises your design. Understanding the core difference is key.

Woven geotextiles are manufactured by interlacing yarns, providing high tensile strength for reinforcement. Non-woven geotextiles are created by bonding fibers, resulting in a felt-like, permeable fabric ideal for filtration, separation, and drainage. The key difference is strength versus water flow.

While they are both fabrics used in civil engineering, their internal structures are fundamentally different, leading to vastly different applications. Selecting the correct type is not just a suggestion; it's a critical decision that directly impacts the stability and longevity of your project. Let's break down where each type excels.

How are non-woven and woven geotextiles made differently?

On a roll, they can look similar. But specifying one for the other’s job is a critical error. The manufacturing process itself explains why each has a very different function.

Woven geotextiles are made by interlacing strong, flat yarns on a loom, creating a structured, grid-like fabric. Non-woven geotextiles are made by needle-punching or thermally bonding loose fibers together, forming a random, felt-like mat with high porosity.

The manufacturing method is the most fundamental distinction and dictates every performance characteristic. One process creates a high-strength, low-stretch material, while the other creates a permeable, flexible material.

Manufacturing at a Glance

| Feature | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Process | Yarns are interlaced at right angles on a loom, like cloth. | Staple fibers or continuous filaments are bonded by needle-punching or heat. |

| Internal Structure | Uniform, grid-like pattern with distinct pore openings. | Random, three-dimensional structure of entangled fibers. |

| Result | A strong, stiff sheet with high tensile strength. | A thick, permeable, felt-like fabric with high flexibility. |

This difference in structure is why you cannot substitute one for the other without compromising your design.

What are the main performance differences between woven and non-woven geotextiles?

A technical data sheet can be confusing. Judging a fabric by weight alone can lead you to choose a geotextile that is completely wrong for the stress or flow demands of your project.

Woven geotextiles offer high tensile strength and low elongation, making them stiff and strong for reinforcement. Non-wovens have high permeability and elongation, making them excellent for filtration, drainage, and conforming to uneven ground.

Understanding these key trade-offs is essential for proper specification. One provides structural support, while the other manages water.

Performance Comparison

| Property | Woven Geotextile | Non-Woven Geotextile |

|---|---|---|

| Tensile Strength | High. Resists stretching under heavy loads. | Lower. Functions more like a separator than reinforcement. |

| Elongation at Break | Low (5-25%). Stiff and stable. | High (>50%). Flexible and conforms to surfaces easily. |

| Permeability | Low. Water flows through slowly. | High. Water passes through easily. |

| Filtration Ability | Fair. Uniform pores can clog with fine soils. | Excellent. Retains fine soil particles while allowing water passage. |

These differences are not a matter of quality; they are a matter of function. Choosing the right one means matching these properties to your project's needs.

Which type of geotextile should I choose for filtration, separation, or reinforcement?

You understand the properties, but the critical question remains: which one do you actually use for your specific application? Using a drainage fabric where you need reinforcement will lead to structural failure.

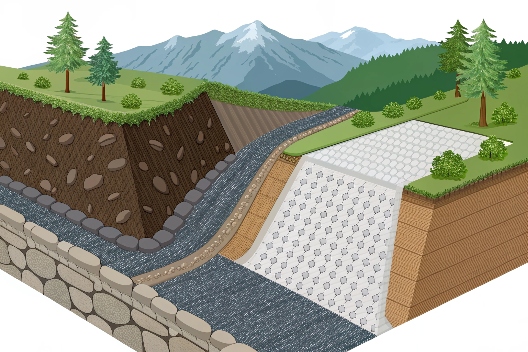

For reinforcement and stabilization, such as under roads or on steep slopes, choose high-strength woven geotextiles. For filtration, drainage, and separation, such as in French drains or as a liner cushion, choose permeable non-woven geotextiles.

The decision should always be based on the primary function the geotextile needs to perform. Making the wrong choice is a costly mistake.

Application Guide

| Function | Recommended Geotextile | Why? |

|---|---|---|

| Reinforcement | Woven | High tensile strength provides structural support and load distribution. |

| Separation | Non-Woven | Prevents two soil layers (e.g., mud and gravel) from mixing. |

| Filtration | Non-Woven | Allows water to pass through while holding back soil particles, preventing clogging. |

| Drainage | Non-Woven | High in-plane flow capacity helps convey water within the soil system. |

| Liner Protection | Non-Woven | The thick, flexible fabric acts as a cushion to protect geomembranes from puncture. |

How can I ensure long-term performance when selecting geotextile materials?

You've chosen the right type, but how do you select a quality product from the various options? Relying on a single metric could lead to specifying a material that fails to meet long-term project requirements.

Ensure performance by matching the material's data sheet to your project's specific needs—strength (kN/m) for wovens and weight (g/m²) for non-wovens. For the best recommendation, provide your supplier with your project details and goals.

The numbers on the data sheet are your guarantee of performance. For reinforcement, the ultimate tensile strength (measured in kN/m) is the most critical value. For filtration and separation, the mass per unit area (g/m² or oz/yd²) often correlates with durability and filtration capacity. However, the best approach is to move beyond generic specs. Every site is different. Providing your supplier with project details—soil type, load conditions, required flow rates—allows us to recommend a product that is not just suitable, but optimized for your application, ensuring both performance and cost-efficiency.

Conclusion

The choice is simple: woven for strength and reinforcement, non-woven for filtration and drainage. The best selection always depends on the specific demands of your project.