You're choosing a geocell for your project, but you're faced with a choice: textured or smooth? It seems like a small detail, but you worry that picking the wrong one could lead to soil slippage on a slope or a weaker road base, compromising your entire project.

Textured geocells provide significantly better soil interaction due to their rough, embossed surface. This texture creates a much higher interface friction, locking the infill soil in place and preventing it from sliding, which is crucial for slope and channel applications.

Kao a dobavljač geosintetike, I often get asked if the texture is just a marketing gimmick. It's not. The choice between textured and smooth is one of the most important decisions you'll make, as it directly relates to the geocell's ability to "grip" the soil. Think of it like a car tire: a smooth racing slick is great for a dry track, but on a wet, gravelly hill, you need deep treads. The same logic applies to geocells.

What structural differences between textured and smooth geocell sheets influence their interaction with soil?

At first glance, the only difference is the surface finish. However, this seemingly minor variation in manufacturing creates a massive difference in how the geocell performs when it is filled with soil and put under load.

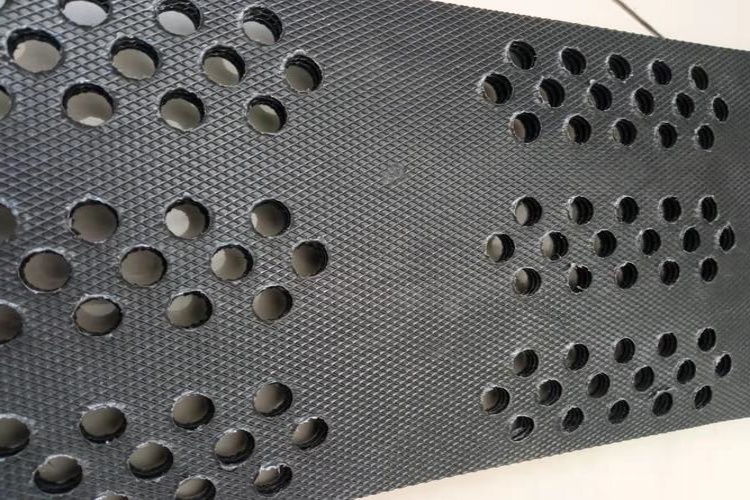

The key structural difference is the surface profile. Textured sheets have a rough, embossed pattern, while smooth sheets are flat. This pattern on textured geocells dramatically increases the surface area and creates a mechanical interlock with the soil particles.

Let's dive deeper into what this means at a practical level. The surface of a geocell is where all the work happens—where the plastic meets the soil. How these two materials interact determines the strength of the entire system.

| Značajka | Textured Geocell | Smooth Geocell |

|---|---|---|

| Surface Profile | Embossed with an irregular, rough pattern (0.3-1.0 mm deep). | Completely flat and uniform on both sides. |

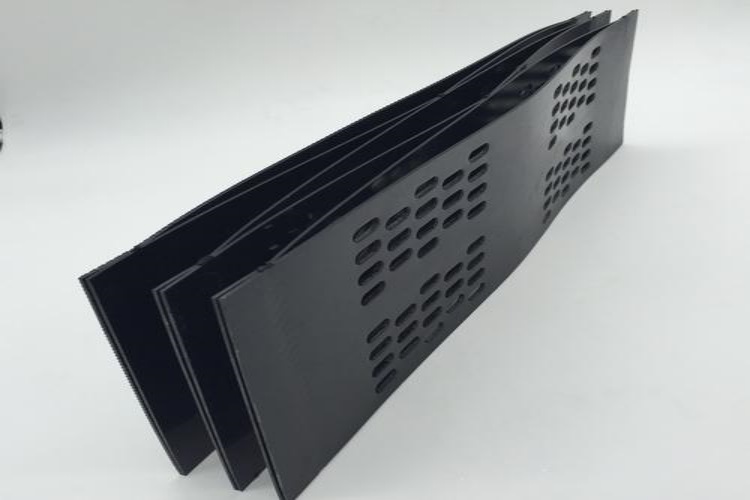

| Manufacturing | A co-extrusion process adds a roughened HDPE layer onto the base sheet. | A single, uniform extrusion process. |

| Feel | Rough to the touch, providing a non-slip grip. | Slippery, with low surface friction. |

| Primary Interaction | Mechanical Interlock: The soil particles physically lock into the textured surface, creating a very strong bond. | Friction Only: The only force holding the soil is the low surface friction between the smooth plastic and the soil. |

This difference in interaction is why a textured geocell can hold soil on a steep slope, while a smooth one would allow the soil to simply slide out.

How does surface texture affect interface friction, confinement efficiency, and load transfer?

The terms "friction" and "confinement" sound technical, but they are the simple forces that make a geocell system work. If these forces are weak, the system will fail.

A textured surface can double the interface friction coefficient compared to a smooth one. This superior grip more effectively transfers stress from the soil to the geocell walls, leading to much higher confinement efficiency and better load-bearing capacity.

Let's break down how this works. When you put a load on the soil inside a geocell, the soil tries to push outwards. The geocell walls push back, "confining" it. The effectiveness of this confinement depends entirely on the friction between the wall and the soil.

| Performance Metric | Textured Geocell | Smooth Geocell | The Real-World Impact |

|---|---|---|---|

| Interface Friction Coefficient | High (0.40 - 0.60) | Low (0.20 - 0.30) | A textured geocell has a much stronger "grip" on the soil, preventing it from slipping under load or from the force of gravity on a slope. |

| Confinement Efficiency | Izvrsno | Moderate | Because the soil is locked in place, the entire geocell-and-soil composite acts as a single, solid block, which is much stronger. |

| Load Transfer | Vrlo visoko | Niska | Stress is transferred efficiently from the soil to the strong tensile properties of the geocell walls, allowing the system to support much heavier loads. |

In simple terms, the texture ensures that the geocell and the soil work together as a team. With a smooth geocell, the soil and the plastic often act as two separate, weaker elements.

In which engineering applications does a textured geocell offer clear advantages?

Choosing the wrong surface type is not just inefficient; it can be dangerous. A smooth geocell used on a steep slope is an invitation for failure. It's critical to match the surface to the job.

Textured geocells are clearly superior for any application involving a slope, potential water flow, or the need for maximum soil stability. Smooth geocells are only suitable for flat, low-stress applications where cost is the primary driver.

As a supplier, I use a very simple rule of thumb to guide my clients: if the ground is not flat, you need texture. Here is a more detailed breakdown of the ideal uses for each type.

| Recommended for Textured Geocells | Recommended for Smooth Geocells |

|---|---|

| Slope Protection: The high friction is essential to prevent soil from sliding down embankments, levees, and roadway slopes. | Road Base Reinforcement (on flat ground): When used on a flat subgrade, the geocell's main job is vertical load distribution, not slip prevention. |

| Channel and Shoreline Protection: Prevents erosion by locking soil and rock in place against the force of moving water. | Foundation Support: For improving the bearing capacity of weak soils under building pads on level terrain. |

| Retaining Walls: Provides a better interlock with the backfill material, increasing the overall stability of the wall structure. | General Load Distribution (on flat ground): For applications like parking lots or storage yards where the primary goal is to prevent rutting. |

| Vegetated Slopes: The texture helps anchor the topsoil and plant roots, creating a stable, green surface. | Cost-Sensitive Projects (on flat ground): Smooth geocells can be 10-20% cheaper, making them a viable option where high friction is not required. |

How can I select the appropriate geocell surface type based on my project requirements?

You understand the difference, but now you need to make the final decision. You want a clear, simple way to justify choosing one type over the other for your specific project.

The decision is primarily driven by the slope angle. For any slope steeper than 1V:3H (about 18 degrees), a textured geocell is mandatory. For flatter terrain, you can then consider the infill type and budget to make the final choice.

I use a quick checklist with my clients to make this decision easy and defensible. By answering these few questions, you can be confident in your choice.

-

What is the slope of the installation area?

- Steeper than 1:3 (e.g., 1:2, 1:1.5): Textured is required. The risk of slippage is too high for a smooth surface.

- Flatter than 1:3: You can consider either type. Move to the next question.

-

Will there be moving water (rain runoff, channel flow)?

- Yes: Textured is highly recommended. The extra grip is needed to resist the erosive forces of water.

- No: You can still consider either type.

-

What is the primary function of the geocell?

- Erosion control, slope stability, or shoreline protection: Choose Textured. The core function relies on high friction.

- Rut prevention or load distribution on flat ground: Smooth is an acceptable option.

-

What is your project budget?

- Performance is the top priority: Choose Textured for peace of mind, even on flat ground, as it offers superior all-around performance.

- Budget is very tight (and the ground is flat): Smooth can be a cost-effective choice if the conditions are appropriate.

By following this logic, you can ensure that you are selecting the right geocell surface for both the safety and the long-term success of your project.

Zaključak

The choice is simple: for slopes or erosion control, textured geocells are essential for their superior grip. For flat, basic load support applications, smooth geocells can be a cost-effective alternative.