Selecting a geotextile can feel overwhelming. With hundreds of types, weights, and specifications, choosing the wrong one can lead to costly project failures, from clogged drainage systems to compromised structural integrity. A simple mistake in a spec sheet can undermine your entire project before the first roll is even deployed.

This guide simplifies the selection process by breaking it down by real-world application. As a supplier, we will walk you through the exact geotextile types and specifications required for different projects—from roads and landfills to riverbanks and tunnels. This ensures you match the right material to your engineering needs, preventing costly rework and ensuring long-term performance.

Before diving into specific applications, it's essential to understand the fundamental building blocks of geotextile selection.

Understanding Geotextile Types and Core Functions

Geotextiles are engineered fabrics used in civil engineering and environmental projects. Their primary purpose is to solve soil and ground-related problems. Every selection process must begin by identifying which of the five core functions the geotextile needs to perform:

- Separation: Preventing two different soil or aggregate layers from mixing, such as keeping a gravel road base from disappearing into a soft subgrade.

- Filtriranje: Allowing water to pass through the fabric while retaining soil particles, which is critical for preventing drainage systems from clogging.

- Drainage: Facilitating the movement of water within the plane of the geotextile itself, often used in composite products.

- Pojačanje: Adding tensile strength to a soil mass to improve its load-bearing capacity, such as in retaining walls or steep embankments.

- Zaštita: Acting as a durable cushioning layer to protect an underlying material, like a geomembrane liner, from puncture.

These functions are delivered by three main types of geotextiles:

- Nonwoven Geotextiles: These have a felt-like structure and excel at filtration, drainage, and protection due to their high permeability and cushioning ability.

- Woven Geotextiles: These have a grid-like, interlaced structure, giving them high tensile strength and making them ideal for separation and reinforcement.

- Composite Geotextiles: These combine different materials, such as a geotextile bonded to a geomembrane, to perform multiple functions like filtration and seepage control simultaneously.

Key Selection Criteria: Strength, Permeability, and Durability

Once you know the primary function, you can select a product based on specific technical parameters. The most important criteria include:

- Mass per Unit Area (Grammage/GSM): Measured in g/m², this indicates the fabric's weight and thickness. Heavier fabrics (e.g., 400-800 g/m²) are typically used for high-stress applications like protection and reinforcement, while lighter fabrics (100-300 g/m²) are common for general separation and filtration.

- Vlačna čvrstoća: Measured in kN/m, this is the fabric's ability to resist pulling forces. It is the most critical parameter for reinforcement applications.

- Tear Strength: Measured in kN, this indicates the fabric's resistance to tearing during installation and service.

- Propusnost: The rate at which water can pass through the fabric. This is essential for all filtration and drainage functions.

- Polymer Type: The choice between Polyester (PET) and Polypropylene (PP) is crucial. PET offers excellent strength and creep resistance, making it suitable for long-term reinforcement. PP provides excellent chemical resistance, especially against alkalis, making it ideal for projects involving concrete or certain industrial wastes.

Always verify these parameters against accredited test reports (e.g., ISO 9001) to ensure the product meets your design requirements.

Geotextile Selection for Roads, Pavements, and Airports

For transportation infrastructure, the main goals are to reinforce the subgrade, filter water, and prevent settlement.

Road Subgrade Construction

For separating the subgrade from the aggregate base in standard roads, we recommend a spunbond nonwoven geotextile (PET or PP) with a grammage of 300–400 g/m². Key specifications include a minimum tensile strength of ≥8 kN/m and excellent permeability (vertical permeability coefficient ≥1×10⁻¹ cm/s) to prevent water pressure buildup. This separates the layers while allowing water to drain freely.

Pavement Maintenance and Rehabilitation

When repaving an old road, a spunbond nonwoven geotextile of 150–250 g/m² is used. Its high tensile strength, wear resistance, and compatibility with asphalt help prevent reflective cracking from the old surface from appearing on the new one, significantly extending pavement life.

High-Load Applications (Highways and Airports)

For high-stress areas like major highways and airport runways, a high-strength woven geotextile (PET) is required. The grammage should be in the 500–800 g/m² range with a minimum tensile strength of ≥20 kN/m and a tear strength of ≥3 kN. It is almost always used in combination with a geogrid to create a composite system that can effectively distribute heavy loads and prevent long-term settlement. For high-grade highways, PET is preferred for its superior long-term weather resistance, with strength retention of over 80%.

Geotextile Selection for Erosion Control and Slope Protection

When dealing with slopes, the primary goal is to prevent soil loss due to water runoff while allowing vegetation to establish. For slopes up to 45°, we recommend a flexible spunbond nonwoven geotextile made from Polypropylene (PP). Its flexibility allows it to conform tightly to the slope's surface. A grammage of 250–350 g/m² is typically sufficient. This geotextile is often used as part of a larger system with eco-bags or other revegetation products, providing immediate stability while the plant roots develop and create a natural, long-term solution.

Geotextile Selection for Coastal, River, and Marine Works

In hydraulic engineering, geotextiles must withstand the constant force of moving water. The selection depends heavily on the specific environment.

- Riverbank Protection: For river channels with moderate flow rates (≤3 m/s), a woven geotextile (PET) is ideal due to its excellent scour resistance. We recommend a grammage of 300–500 g/m² and a minimum tensile strength of ≥15 kN/m. It is placed on the riverbank before armoring with rock or concrete to prevent the underlying soil from being eroded.

- Coastal Applications: For seawalls and other coastal projects, the material must resist salt-mist corrosion. A Polyester (PET) geotextile with a special anti-corrosion coating is the only suitable choice to ensure long-term durability in this aggressive environment.

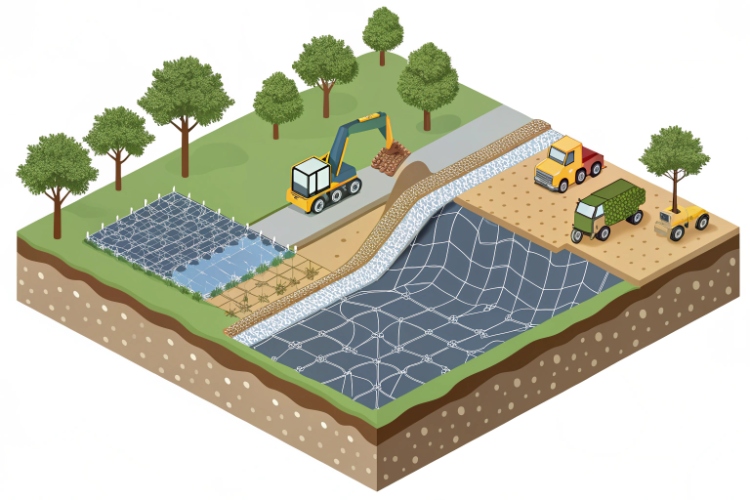

Geotextile Selection for Landfills and Environmental Containment

In environmental applications, geotextiles serve to protect liners, filter contaminated liquids, and provide structural stability.

Landfill Systems

Landfills require robust geotextiles that can withstand harsh chemical environments and high mechanical stress. We recommend a spunbond needle-punched nonwoven geotextile made from Polyester (PET) due to its excellent acid and alkali resistance. A very heavy grammage of 400–600 g/m² is used. It is placed both above and below the HDPE geomembrane liner to act as a protective cushion, preventing puncture from waste or the underlying drainage stone. A minimum tensile strength of ≥12 kN/m is required, and the product must have environmental certifications (e.g., RoHS, REACH) ensuring no harmful substances will leach out.

Wastewater Treatment and Mine Restoration

- Wastewater Filtration: In treatment plants, a specialized geotextile filter cushion made of composite fibers (300-400 g/m²) can replace traditional sand filter layers, offering a high porosity (≥70%) for efficient filtration.

- Mine Restoration: For mine reclamation, a biodegradable eco-geotextile (200-300 g/m²) is used. It provides initial erosion control and soil stabilization, then slowly degrades over 3–5 years as vegetation takes over.

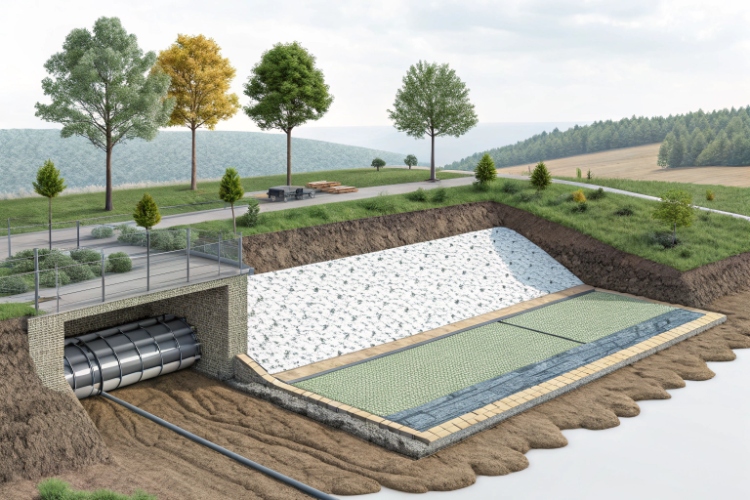

Tunneling Applications

In tunnels, a soft and flexible spunbond nonwoven geotextile (PP) with a grammage of 200–300 g/m² is used. Its primary function is to act as a protective cushioning layer for the waterproofing membrane, preventing it from being punctured by sharp rocks or sprayed concrete.

Practical Tips for Matching Geotextile Specifications to Project Conditions

Finalizing your selection involves more than just matching an application to a product. Consider these practical factors:

- Cost vs. Performance: While PP nonwovens are often the most cost-effective option for general-purpose tasks, do not substitute them where PET's long-term strength or a woven fabric's reinforcement capability is required. The initial savings will be erased by the high cost of failure.

- Environmental Conditions: For projects in cold regions (-30°C to -10°C), you must specify a cold-resistant geotextile formulated with additives to prevent it from becoming brittle. Ensure the product maintains at least 70% of its tensile strength in low-temperature conditions.

- Verify Compliance: Always request documentation. At a minimum, the supplier should provide ISO 9001 certification and batch-specific test reports. For environmental projects, demand proof of compliance with standards like RoHS or REACH.

Zaključak

Selecting the right geotextile is a process of precise engineering, not guesswork. By starting with the primary function, analyzing the site conditions, and then matching the application to the detailed specifications outlined in this guide, you can confidently source the correct material. This application-based approach removes ambiguity and ensures your project benefits from the full strength, filtration, and protective capabilities that only the right geotextile can provide.