Build a strong retaining wall, but after the first heavy rainy season, it starts to bulge and crack. The immense, invisible force of water pressure is trying to push it over.

For retaining walls, the correct choice is a nonwoven needle-punched geotextile. Its job is to act as a filter, allowing water to pass through to a drainage system while preventing soil particles from clogging it, which relieves the dangerous buildup of hydrostatic pressure.

Kao a dobavljač geosintetike, I've seen more retaining wall failures caused by poor water management than any other factor. The wall itself can be perfectly strong, but if water can't escape from the soil behind it, it will fail. A simple, properly installed layer of geotextile is the single most important element for ensuring the long-term durability of your wall. Let's explore exactly what it does and how to choose the right one.

What functions does geotextile serve in retaining wall systems?

You see a fabric layer specified in the design, tucked behind the wall. It seems thin and insignificant compared to the heavy blocks and soil, making you wonder what it's really doing.

A geotextile performs three critical jobs simultaneously: it separates the backfill soil from the clean drainage gravel, filters water by letting it pass while holding back soil particles, and helps drain water away, preventing pressure buildup.

Think of the geotextile as the smart, hard-working gatekeeper for your retaining wall's entire drainage system. Each function is critical to preventing failure.

1. Razdvajanje

The geotextile is placed like a curtain between the native soil you are holding back (backfill) and the clean gravel drainage zone directly behind the wall. It acts as a barrier, a bouncer at a club, preventing the two materials from mixing. Without this separation, fine soil particles would quickly wash into the gravel, turning your expensive drainage zone into a muddy, non-functional mass.

2. Filtriranje

This is its most important job. The geotextile acts like a high-tech coffee filter. Water from the soil can easily pass through the fabric, but the soil particles are trapped on the other side. This allows water to escape the backfill and enter the drainage zone, relieving the hydrostatic pressure that wants to push your wall over.

3. Drainage

While the geotextile itself isn't a primary drainage channel, its filtration function enables the entire drainage system to work. By keeping the gravel clean, it ensures there is a clear, open path for the filtered water to flow down to the bottom of the wall and exit through a drainpipe.

Should woven or nonwoven geotextile be used for retaining walls?

You're placing an order and see two main options: woven and nonwoven. They look and feel completely different, and choosing the wrong one will compromise your entire drainage system.

Always use a nonwoven geotextile for retaining wall drainage and filtration. Its felt-like, three-dimensional structure is excellent for letting water pass through while trapping soil. Woven geotextiles are for reinforcement and stabilization, not filtration.

This is one of the most common points of confusion I clarify for my clients. The difference in performance is huge, and using the wrong type will lead to failure. Here’s a simple breakdown:

| Značajka | Tkani geotekstil | Netkani geotekstil |

|---|---|---|

| Struktura | Tightly interlaced, flat yarns (like a tarp) | Random, interlocking fibers (like felt) |

| Primary Use | Pojačanje & Stabilization (e.g., under roads) | Filtration, Separation & Drenaža |

| Water Flow | Low, flows along yarn planes | High, flows directly through the fabric |

| Retaining Wall | Incorrect Choice - Clogs easily, poor filtration | Correct Choice - Excellent filtration |

A woven geotextile has very small, uniform openings. When fine soil particles hit it, they plug these openings, and the fabric quickly clogs, stopping water flow entirely. A nonwoven geotextile has a complex, random fiber structure. Water finds many paths to get through, and if one area gets blocked, others remain open. It's designed specifically for this filtration task.

What strength and filtration properties are required for retaining wall geotextiles?

You're looking at a data sheet for a nonwoven geotextile, and it’s full of technical terms. You need to know which numbers actually matter for making a reliable choice for your wall.

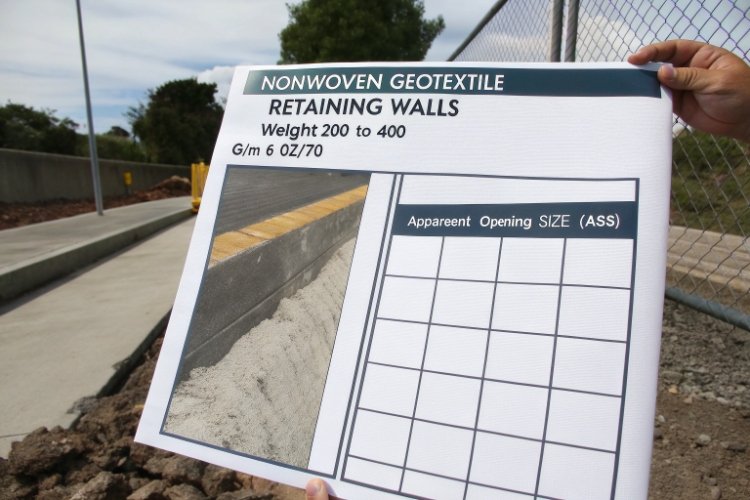

Focus on a weight between 200 to 400 g/m² (6 to 12 oz/yd²). This provides good durability during installation. Also, ensure it has high permeability to pass water easily and a small Apparent Opening Size (AOS) to effectively retain soil particles.

Let's demystify the key specifications you'll see on a product data sheet so you can order with confidence.

Key Geotextile Properties

- Weight (g/m² or oz/yd²): This is the simplest indicator of the fabric's thickness and robustness. A heavier fabric (e.g., 270 g/m² or 8 oz/yd²) is tougher and more resistant to being torn or punctured by sharp rocks during installation than a lighter one. For most retaining walls, a mid-range weight of 200-400 g/m² is the sweet spot.

- Propusnost: This measures how quickly water can pass directly through the fabric. A higher permeability value is better, as it means the geotextile can handle large volumes of water during heavy rain without pressure building up.

- Prividna veličina otvora (AOS): This indicates the largest particle size that can effectively be stopped by the filter fabric. It's often expressed as a U.S. Sieve number (e.g., 70 or 80). You want an AOS that is small enough to stop your specific backfill soil from passing through but large enough not to clog instantly. A supplier can help you match this to your soil type.

How can I choose the right geotextile based on wall type and site conditions?

A small garden wall has different needs than a massive highway embankment. You need a practical way to scale your material selection to match the risk and requirements of your specific project.

The geotextile is part of a system. For small walls, a single layer of nonwoven fabric may suffice. For tall, critical walls (often built with geogrids), the geotextile serves as the filtration component in a much larger drainage and reinforcement system.

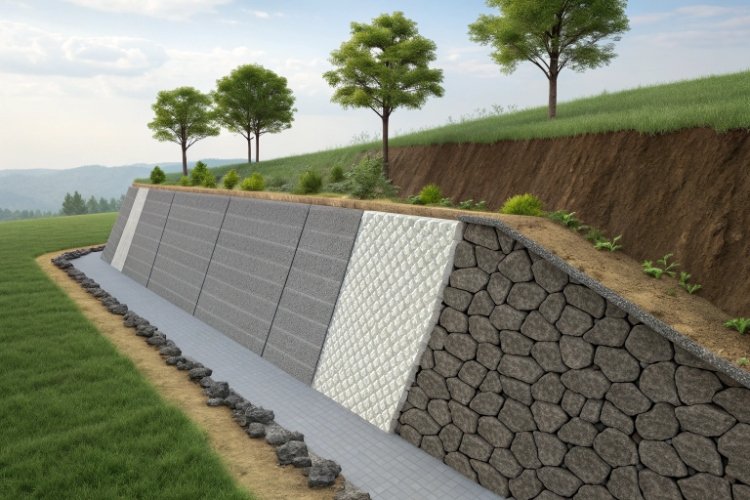

The key is to think in terms of creating a complete, highly effective drainage path. A modern retaining wall design is a system of compatible materials working together.

The Complete Drainage System

For any critical retaining wall, a simple fabric sheet is not enough. A proper design pairs the geotextile with a physical drainage layer. This typically involves:

- Pojačanje: Geogrid layers placed within the backfill soil to increase its strength and stability (for taller walls).

- Filtriranje: A netkani geotekstil placed between the native soil and the drainage gravel.

- Drainage: A clean, angular gravel layer, typically 30-45 cm (12-18 inches) thick, placed directly behind the wall blocks. This zone acts as a drainage "chimney."

- Collection: A perforated pipe at the base of the gravel zone to collect the water and carry it away from the wall's foundation.

This combined system can reduce hydrostatic pressure by over 90%. By choosing the right nonwoven geotextile as your filter, you ensure this entire system remains clean and functional for the life of the wall.

Zaključak

The right nonwoven geotextile is a vital component for a retaining wall’s drainage. It prevents clogging and relieves water pressure, ensuring the long-term stability and success of your structure.