You are on-site, a fresh roll of composite geomembrane at your feet. One side is a tough fabric, the other smooth plastic. Placing it upside down is a simple mistake that can lead to a catastrophic failure of your entire containment system.

For composite geomembranes, the geotextile (fabric) side almost always faces down against the soil. The fabric layer acts as a built-in cushion to protect the impermeable geomembrane from being punctured by the subgrade, leaving the smooth plastic geomembrane side facing up.

Kao a supplier, this is one of the first and most critical questions I get from new clients. The orientation is not a matter of preference; it's fundamental to the product's design. Getting this wrong completely defeats the purpose of using a composite material and exposes your project to unnecessary risk. Let's walk through how this material works and how to install it correctly every time.

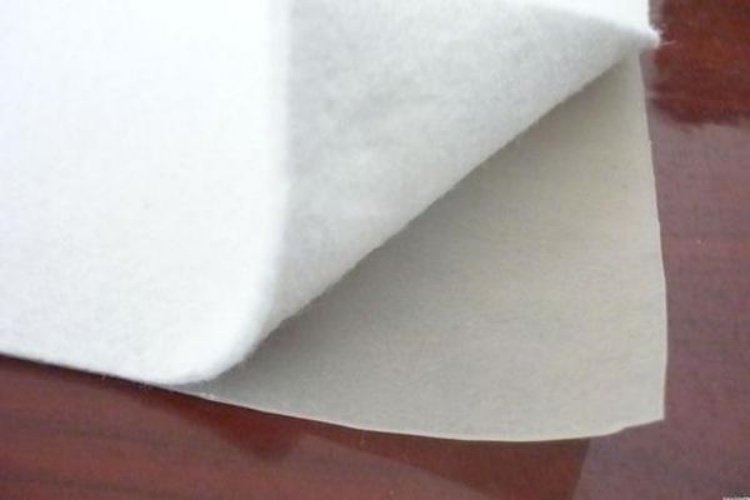

What is a one-fabric–one-membrane composite geomembrane?

You hear the term "composite geomembrane" and wonder if it's just a separate fabric and liner that you have to lay together. It seems like a lot of extra work and hassle.

It's a single, factory-bonded product. We take a tough, puncture-resistant nonwoven geotextile and heat-fuse it directly to an impermeable geomembrane (like HDPE or LLDPE). This creates one integrated roll that combines protection and waterproofing, saving you significant time and labor on site.

Think of it as a pre-assembled system designed for efficiency and performance. Instead of trying to manage and align two separate layers in potentially windy or difficult site conditions, the work is already done. The factory bonding process ensures there is no slippage between the layers and guarantees a consistent, high-quality product. This single-roll solution makes deployment much faster and removes a common source of installation error. The geotextile acts as the geomembrane's bodyguard, shielding the critical impermeable layer from damage. In my experience, for projects with less-than-perfect ground conditions, this built-in protection is a non-negotiable feature for long-term security. It is the perfect marriage of strength and impermeability.

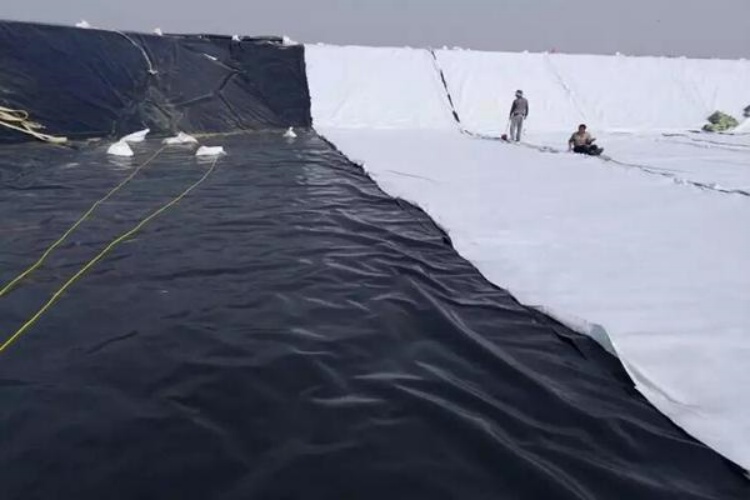

Should the geotextile side face up or down?

This is the most crucial decision you'll make when unrolling the material. A 50/50 choice with major consequences. Get it wrong, and your liner's primary defense is facing the wrong way.

The geotextile side faces DOWN. Its main job is to protect the geomembrane from being punctured by sharp rocks, roots, or uneven ground in the subgrade. The smooth geomembrane layer must face UP to form the waterproof barrier that contains the liquid or waste.

I always give my clients a simple rule to remember on site: "Fabric faces the danger." For nearly every application—ponds, canals, landfills, mining pads—the primary danger of puncture comes from the earth you are laying the liner on. The subgrade, even when well-prepared, can have hidden stones or settle unevenly over time. Placing the tough geotextile fabric down provides a constant, built-in cushion that shields the thin, impermeable geomembrane from this threat. This orientation also creates the optimal surface for welding. The smooth, clean geomembrane side facing up allows for perfect heat fusion between panels, ensuring a strong, continuous, and leak-proof seal across the entire project area. This is the standard, accepted, and correct installation method for over 95% of all projects.

Does the facing direction change under different applications?

You understand the "fabric down" rule for a standard pond, but what about more complex jobs? What if you are placing heavy, sharp rock on top of the liner? Does the rule ever change?

Yes, but only in very specific cases. The "fabric faces the danger" rule still applies. If the primary puncture threat comes from the material being placed on top of the liner, then you would flip the orientation and place the geotextile side UP.

While the standard "fabric down" method is the default, a smart installer always analyzes the specific risks of their project. You must identify where the biggest threat is coming from. A well-prepared soil subgrade is generally a lower risk than, for example, dumping large, sharp-edged rocks (riprap) directly onto the liner for erosion control. In that specific scenario, the danger is from above, so the protective fabric must face up. This is a special case, not the norm. Using a decision table can help clarify this for your team on site. Incorrectly assessing the primary threat and using the wrong orientation is a costly mistake that can lead to immediate liner damage during the backfilling or covering phase of the project.

| Primjena | Primary Puncture Threat | Correct Orientation | Obrazloženje |

|---|---|---|---|

| Pond / Reservoir / Canal | Soil Subgrade | Geotextile Down | Protects liner from stones and roots in the ground. |

| Landfill / Mining Pad | Soil Subgrade | Geotextile Down | Provides protection and sub-surface drainage path. |

| Erosion Control w/ Riprap | Sharp Rock Cover | Geotextile Up | Protects liner from puncture by heavy, sharp rock. |

| Concrete Tank Lining | Abrasion/Rough Concrete | Geotextile Down | Cushions liner against the hard, abrasive concrete surface. |

What common mistakes should be avoided during installation?

You've oriented the liner correctly, but the job isn't done. A successful installation depends on avoiding several common pitfalls that can compromise the entire system, no matter which way the liner is facing.

The most critical mistakes are poor subgrade preparation, improper welding, and failing to place a protective cover promptly. Each of these can lead to liner damage, leaks, and a failed project, wasting all the investment in high-quality materials.

I've seen projects fail not because of the material, but because of a lack of attention to these fundamental installation steps. A high-quality composite geomembrane can be rendered useless if it's not installed with care.

- Poor Subgrade Preparation: This is mistake number one. You cannot just roll the liner out over rough ground. The surface must be smooth, compacted, and free of any sharp objects like rocks, roots, or construction debris. Any sharp point creates a stress concentrator that can puncture the liner over time.

- Improper Welding: The seams between panels are the most vulnerable part of any lining system. Welding must be done by trained technicians using specialized equipment. They need to perform trial welds every day to ensure the machine is calibrated for the site's temperature and humidity. Rushing the welding or using unqualified labor is a direct path to leaks.

- Delayed Cover Placement: The geomembrane itself is the waterproof barrier, but it is not designed to be exposed to sunlight and physical damage indefinitely. After welding and testing are complete, the final cover soil or protective layer should be placed as soon as possible. Letting the liner bake in the sun can cause wrinkles and UV degradation, while leaving it exposed to construction traffic is an invitation for damage.

Zaključak

Correctly installing a composite geomembrane is simple: the fabric faces the danger. For nearly all jobs, this means the geotextile goes down. By getting this right and avoiding common installation mistakes, you ensure a durable, long-lasting containment system.