Iznenadna kiša natopi vaše skupe GCL role tijekom postavljanja. Njihova uporaba mogla bi dovesti do potpunog kvara, ali njihova je zamjena ogroman, neočekivani trošak. Morate znati mogu li se spasiti.

Općenito, ne. Geosintetička obloga od gline (GCL) koja se znatno smoči prije nego što je prekrivena zemljom bubri bez pritiska, ugrožavajući njezinu unutarnju strukturu. Samo vrlo lagana površinska vlažnost omogućuje potencijalnu ponovnu upotrebu nakon pažljivog pregleda i odobrenja inženjera.

Kao a dobavljač geosintetike, ovo je bolan poziv od klijenta. Vidio sam kako se čitavi projekti suočavaju s velikim neuspjesima zbog jedne neočekivane kišne oluje. The natrijeva bentonitna glina unutar deke je poput superupijajuće suhe spužve koja čeka vodu. Ako se hidratizira u krivo vrijeme - prije nego što se zakopa u zemlju - njegova jedinstvena moć bubrenja se gubi, a njegova sposobnost vodootpornosti može biti trajno izgubljena. Kako biste izbjegli ovu skupu pogrešku, morate razumjeti što se događa kada se smoči i koje su vam mogućnosti.

Što se događa s vodootpornim pokrivačima od bentonita kada se smoče prije postavljanja?

Vaš GCL se smočio i iako izgleda malo natečen, ne čini se uništenim. Ali ispod površine, bentonit nekontrolirano bubri, oštećujući unutarnju strukturu i stvarajući skrivene slabe točke.

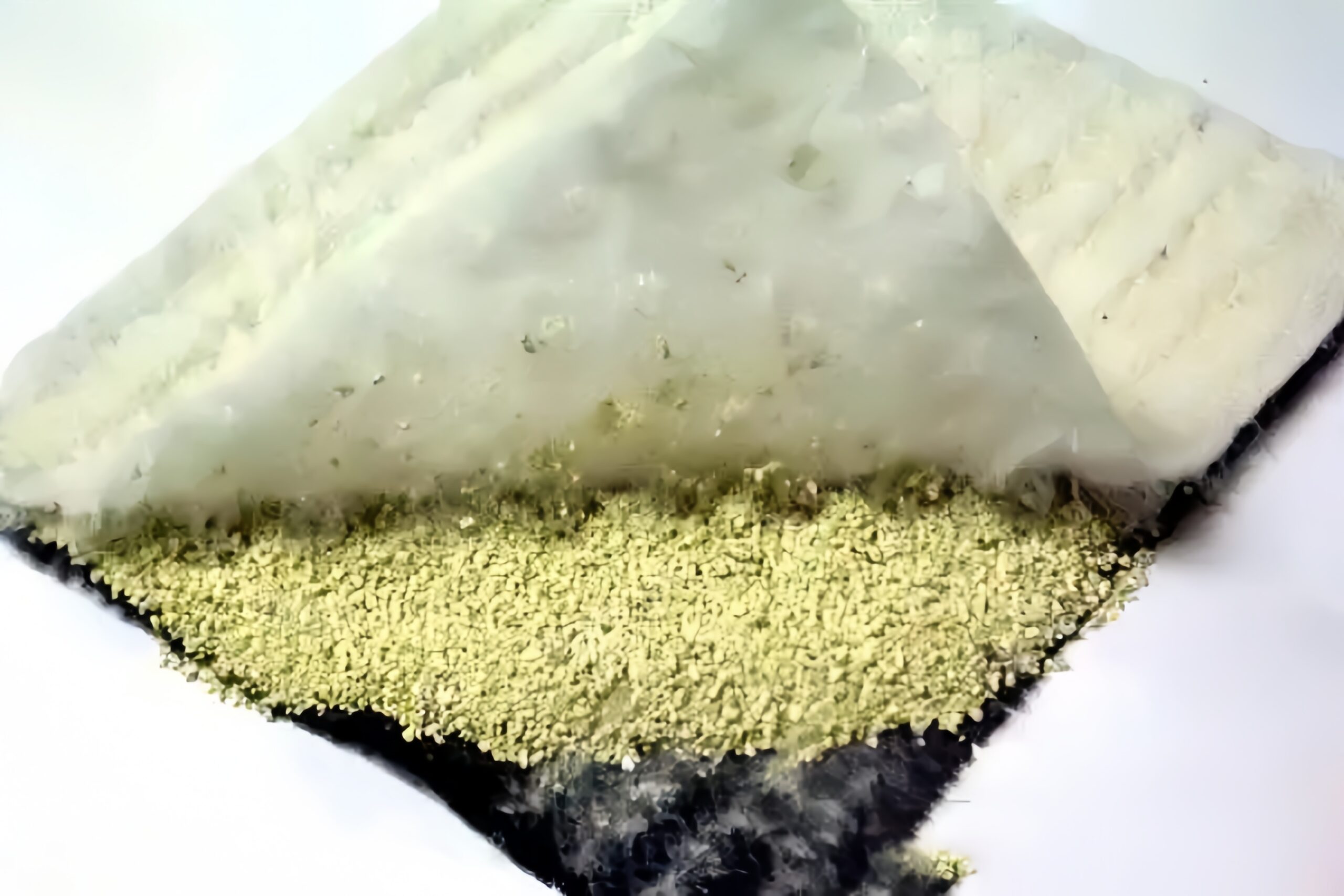

The bentonite clay "free swells" bez ograničavajućeg pritiska pokrova tla. Ova nekontrolirana ekspanzija oštećuje iglana vlakna koja drže pokrivač na okupu, uzrokujući da se bentonit skuplja, pomiče i gubi svoju jedinstvenu sposobnost brtvljenja.

Problem "Free Swell"

GCL radi jer je bentonit zarobljen između dva sloja geotekstila. Kada je zakopan, upija vodu i pokušava se proširiti, ali težina pokrova tla to sprječava. Ovaj ograničavajući pritisak prisiljava nabubreli bentonit da se stisne u gusti, nepropusni, monolitni gel. Tako se stvara vodonepropusna barijera.

-

Nekontrolirana ekspanzija

When a GCL gets wet in the open air, there is no confining pressure. The bentonite is free to swell as much as it wants. Instead of forming a dense seal, it expands outward, like a loaf of bread rising. This "free swell" stavlja ogroman pritisak na iglana vlakna koja povezuju dva sloja geotekstila, istežući ih i ponekad lomeći. -

Gubitak ujednačenosti

Nakon što je unutarnja struktura ugrožena, bentonit se više ne drži ravnomjerno na mjestu. Može se nakupiti na nekim područjima i migrirati dalje od drugih, stvarajući tanke mrlje ili čak praznine bez hidroizolacijske gline. Ako se ovaj oštećeni GCL zatim prekrije i pusti u rad, ta nejednolika područja postaju zajamčeni putevi curenja. Deka je izgubila svoj integritet i ne može joj se vjerovati da će funkcionirati.

Kako mogu procijeniti je li mokri GCL još uvijek upotrebljiv ili treba zamjenu?

Imate natopljeni GCL i tijesan proračun koji vam diše za vratom. Pogrešan poziv znači ili rasipanje dobrog materijala ili instaliranje neispravne barijere koja će kasnije otkazati.

Ako možete ostaviti dubok trag koji se ne oporavlja, GCL je premekan i treba ga zamijeniti. Za konačan odgovor, testirajte sadržaj vlage - sve preko 50% općenito je neupotrebljivo.

Provjere na terenu u odnosu na laboratorijski dokaz

Odlučivanje o sudbini mokrog GCL-a zahtijeva praktičnu procjenu korak po korak. Možete dobiti vrlo dobru predodžbu o šteti na licu mjesta, ali za kritične primjene, laboratorijski test pruža nepobitan dokaz.

-

Jednostavne terenske procjene

Uvijek kažem svojim klijentima da počnu s ovim jednostavnim vizualnim i fizičkim testovima:- Test otiska stopala: Ovo je najpouzdaniji indikator terena. Hodajte po mokrom GCL-u. Ako je pod nogama čvrst poput tepiha na tvrdom podu, vjerojatno je u redu. Ako je mekano i mljackavo kao da hodate po blatu, a vaša čizma ostavlja dubok otisak, bentonit je hidratiziran. Unutarnja struktura je ugrožena i materijal se mora zamijeniti.

- Vizualno oticanje: GCL koji je nabubrio na više od 1,5 puta veću debljinu od izvorne suhe debljine vjerojatno je prošao kroz slobodno bubrenje.

- Grudice bentonita: Za lagano navlaženu GCL, pažljivo otvorite mali kut. Ako su granule bentonita još labave i pjeskovite, možda ćete ih moći spasiti nakon što se osuše. Ako se formira u tijesto ili tvrde grudice, njegova sposobnost širenja je izgubljena.

-

Definitivno laboratorijsko testiranje

Kada je integritet projekta u pitanju, ne možete si priuštiti nagađanje. Industrijski standard je ispitivanje sadržaja vlage (ASTM D2216). Uzima se uzorak mokrog GCL-a i uspoređuje s novim, suhim uzorkom. Pravilno skladišten GCL obično ima sadržaj vlage oko 20%. GCL koji je prerano hidratiziran pokazat će sadržaj vlage od 50% ili više. Ovi podaci inženjeru projekta daju jasne dokaze potrebne za odbacivanje oštećenog materijala.

Koje preventivne mjere pomažu u zaštiti bentonitnih pokrivača od kiše i vlage na licu mjesta?

Najbolji način da se nosite s mokrim GCL-om je da ga uopće nikada nemate. Jedna jedina pogreška tijekom instalacije može poništiti sve vaše brižne napore u planiranju i skladištenju.

Najbolja prevencija je postaviti samo ono što možete pokriti s najmanje 30 cm zemlje istog dana. Pažljivo pratite vremenske uvjete, planirajte rad dok su prozori suhi i uvijek imajte spremne cerade za hitne slučajeve za iznenadne pljuskove.

Pametni instalacijski protokoli

Zaštita vašeg GCL-a tijekom kritične faze instalacije svodi se na planiranje i disciplinu. Vidio sam velike projektne gubitke koji su se mogli spriječiti s nekoliko jednostavnih pravila.

-

Zlatno pravilo: Pokrijte isti dan

Ovo je najvažnije pravilo za instalaciju GCL-a. Nemojte odmotati više GCL-a nego što možete pokriti završnim slojem zemlje (minimalno 30 cm debljine) do kraja radnog dana. Tlo osigurava dvije stvari: zadržavanje potrebno za djelovanje bentonita i vrhunsku zaštitu od kiše. Nakon što je pravilno pokriven, više ne morate brinuti o vremenu. -

Radite s vremenom, a ne protiv njega

Ovo zvuči očito, ali se često zanemaruje pod pritiskom rasporeda. Provjerite vremensku prognozu prije nego što počnete. Ako se predviđa značajna kiša, daleko je jeftinije pauzirati instalaciju na jedan dan nego riskirati uništavanje materijala vrijednog tisuće dolara. -

Uvijek imajte plan za hitne slučajeve

Svako mjesto mora imati velike, otporne cerade i vreće pijeska. Ako započne neočekivani pljusak, neposredni prioritet posade mora biti pokriti sav izloženi GCL. Ova brza akcija može spasiti materijal od oštećenja ako je kiša kratka.

Kako treba skladištiti bentonitne vodootporne deke i kako njima rukovati prije postavljanja kako bi se izbjegla oštećenja?

Vaši GCL-ovi su stigli na lokaciju, ali do instalacije su još dani ili tjedni. Nepravilno skladištenje može uništiti cijelu vašu zalihu prije nego što se uopće odmota, što dovodi do skupih odgoda i zamjena.

Skladištite GCL role na povišenim paletama, potpuno od tla, i držite ih čvrsto prekrivene osiguranim, vodootpornim ceradama. Nikada ih ne ostavljajte nezaštićene, čak i ako je vrijeme vedro.

Zaštita vaše investicije od prvog dana

Onog trenutka kada GCL role stignu na vaše mjesto projekta, one su vaša odgovornost. O ispravnom skladištenju nema pregovaranja i jednostavno ga je implementirati.

-

Pokreni ga s mrtve točke

Nikada nemojte skladištiti GCL role u izravnom kontaktu s tlom. Vlaga iz tla može se polagano uvući u dno valjka, uzrokujući sporu, skrivenu hidrataciju koju nećete otkriti dok ne bude prekasno. Role uvijek stavljajte na drvene palete, podlogu ili drugu platformu koja ih drži povišenima i suhima. -

Držite ga čvrsto pokrivenim

Upotrijebite otporne, vodootporne cerade ili plastične folije da prekrijete cijelu zalihu. Nemojte samo navući pokrivač preko vrha; čvrsto ga zamotajte i otežajte vrećama s pijeskom ili vezicama tako da ga vjetar ne može otpuhati. To štiti GCL ne samo od kiše, već i od rose i visoke vlažnosti. -

Rukujte pažljivo

Vanjski slojevi geotekstila štite bentonit iznutra. Kada pomičete role sa strojevima, koristite odgovarajuće priveznice i opremu kako biste izbjegli trganje ili bušenje pakiranja ili samog GCL-a. Mala poderotina može biti ulaz za vlagu koja oštećuje cijelu rolu.

Zaključak

Mokri GCL je gotovo uvijek izgubljeni GCL. Zaštitite svoju investiciju pravilnim skladištenjem i pametnom instalacijom, postavljajući samo ono što možete pokriti isti dan. Prevencija je ključna.