Worried about containment failure in your project? A single leak can lead to catastrophic environmental damage and financial loss, making reliable seepage control non-negotiable for modern engineering.

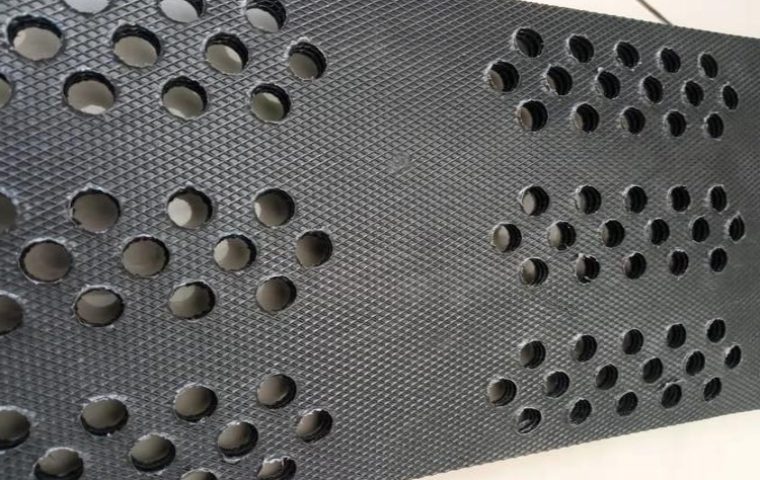

A geomembrane prevents leakage by acting as a physical barrier. Its engineered polymer sheets have extremely low permeability, and when welded together, they form a continuous, monolithic liner that physically blocks the migration of liquids and gases through the containment system.

While this explains the basic function, understanding the specific material science and installation techniques is crucial for any contractor or importer sourcing these materials. The effectiveness of a geomembrane system lies in a combination of its inherent properties, seam integrity, and proper installation. Let's explore the technical details that ensure a leak-free performance for your project.

What material properties make a geomembrane impermeable?

Not all polymer sheets can guarantee containment. Selecting a material without the right properties for your site can result in degradation, punctures, and eventual system failure, compromising your entire project.

A geomembrane's impermeability comes from its high-density polymer structure with extremely low hydraulic conductivity (10⁻¹² to 10⁻¹⁶ cm/s). Additives like carbon black provide crucial UV and chemical resistance, preserving this barrier integrity against long-term environmental exposure.

To make an informed purchasing decision, it's vital to compare these properties against traditional materials. The technical specifications of a geomembrane are not just numbers; they represent a significant leap in performance and reliability over older methods. For B2B buyers, understanding these metrics translates directly to project safety and long-term value.

Key Barrier Properties vs. Traditional Liners

The superiority of a geomembrane is most evident when compared directly with materials like compacted clay:

| Property | Geomembrane (e.g., HDPE) | Compacted Clay Liner (CCL) |

|---|---|---|

| Hydraulic Conductivity | Extremely Low (1 x 10⁻¹³ cm/s) | Low (1 x 10⁻⁷ cm/s) |

| Thickness Required | Thin (0.3-3 mm) | Thick (60-90 cm) |

| Consistency | Uniform, factory-made quality | Variable, depends on site conditions |

| Chemical Resistance | Excellent | Poor to fair |

| Installation Speed | Fast | Slow and weather-dependent |

As the table shows, a geomembrane provides a barrier that is millions of times less permeable than compacted clay, all while saving significant space and installation time.

How does the molecular structure of geomembrane stop water seepage?

It can be difficult to trust that a thin plastic sheet can contain millions of liters of liquid. This skepticism can cause project stakeholders to hesitate, favoring older, less efficient methods.

The dense, crystalline molecular structure of polymers like HDPE leaves virtually no microscopic voids for water molecules to pass through. The long, tightly packed polymer chains create a solid, non-porous physical barrier, fundamentally different from porous materials like soil or concrete.

Think of it as the difference between a solid stone wall and a sponge. The geomembrane functions like the wall at a molecular level. This structure isn't just effective against water; it's also what gives the material its excellent chemical resistance. Harmful chemicals find it just as difficult to penetrate the liner and cause degradation. For an importer or engineer, choosing a material with this inherent structural integrity is the first step toward guaranteeing long-term containment security. It’s a design principle that provides predictable, reliable performance.

Why does welding create a seamless waterproof barrier in geomembrane liners?

Any joint or seam in a liner system is a potential weak point for leaks. If seams are not perfectly sealed, the entire containment system is compromised, regardless of the liner's quality.

Thermal welding melts the surfaces of two overlapping geomembrane sheets. When pressed together, the molten polymer fuses into a single, continuous piece that is as strong as the parent material itself. This process eliminates the seam as a separate joint, creating a truly monolithic barrier.

Creating this "seamless" barrier is a precise engineering process. It relies on specialized equipment and certified technicians to ensure every inch of the seam is perfectly fused.

Methods for Ensuring Seam Integrity

- Hot-Wedge Welding: This is the primary method for long, straight seams. A heated wedge travels between the two sheets, melting the surfaces just before pressure rollers press them together. This technique often creates a dual-track seam with a central air channel, which can be pressurized to test the weld's integrity non-destructively.

- Extrusion Welding: This method is used for repairs, pipe penetrations, and detailed work. An operator uses a handheld tool to extrude a bead of molten polymer onto the seam, effectively "gluing" the pieces together with the same parent material.

For a project manager, specifying and verifying these QA/QC welding procedures is critical to guaranteeing a leak-free installation.

Why should I use geomembrane for seepage control in my project?

You have multiple options for seepage control, and choosing the wrong one can inflate your budget, extend timelines, and introduce unnecessary risk. Traditional methods can seem familiar but often fall short.

You should use a geomembrane because it offers a more reliable, durable, and cost-effective seepage barrier than traditional options like compacted clay. It ensures regulatory compliance, saves valuable airspace, and accelerates construction schedules, providing superior long-term project security.

The decision to use a geomembrane is a strategic business choice rooted in performance, efficiency, and risk management. Unlike soil-based liners whose quality can be inconsistent and weather-dependent, a geomembrane is a manufactured product with certifiable properties. This allows for a much higher degree of quality assurance and predictable performance. For government projects, mining operations, or agricultural reservoirs, the benefits are clear.

The Business Case: Geomembrane vs. Compacted Clay

| Factor | Geomembrane | Compacted Clay Liner (CCL) |

|---|---|---|

| Performance | Extremely low, verifiable permeability. | Moderate permeability, highly variable. |

| Installation | Fast, less weather-dependent. | Slow, requires specific moisture conditions. |

| Space Efficiency | Thin (1-3mm), maximizes containment volume. | Thick (60-90cm), reduces capacity. |

| Cost-Effectiveness | Lower overall installed cost in many cases. | High material and labor costs. |

| Quality Control | Electronic leak detection and seam testing. | Difficult to verify uniformity and compaction. |

This comparison makes it clear why modern engineering standards favor geomembranes for critical containment applications.

Conclusion

A geomembrane's low-permeability molecular structure, combined with seamless thermal welding, creates the most reliable physical barrier available for modern liquid and gas containment projects, ensuring long-term security.