Investing in an HDPE geomembrane is a long-term commitment. But how long is "long-term"? Miscalculating a liner's lifespan can lead to unexpected failures and catastrophic environmental and financial costs.

A properly installed, high-quality HDPE geomembrane can have a service life of over 100 years when buried. If exposed to sunlight, the lifespan is typically reduced to 20-30 years. Key factors influencing longevity are installation quality, UV exposure, material thickness, and operating temperature.

The lifespan of an HDPE geomembrane isn't a single number; it's a projection based on a combination of material science, installation quality, and environmental conditions. While manufacturer warranties often cover 20 to 30 years, lab testing and field evidence show that the functional service life can be far longer. Understanding the factors that contribute to—or detract from—this lifespan is crucial for any engineer or project manager.

How long can HDPE geomembranes typically last under normal conditions?

You need a reliable estimate for your project's design life. Relying on vague promises or marketing claims isn't an option when engineering a multi-decade containment system.

Scientific models predict a service life of over 400 years for HDPE geomembranes buried at 20°C. In real-world exposed conditions, a more conservative estimate is 20 to 30 years. The service life is technically defined as the half-life, when 50% of the antioxidant package is depleted.

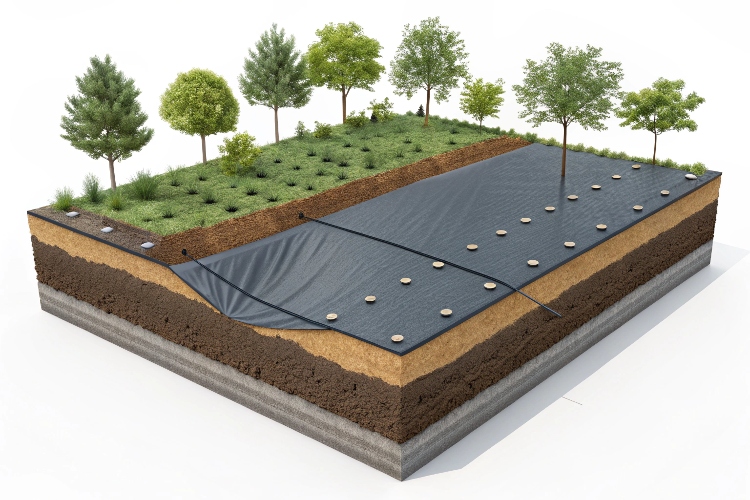

The biggest distinction in lifespan comes down to one simple factor: is the liner buried or exposed?

- Buried/Covered Installations: When shielded from UV radiation and extreme temperature fluctuations by soil, water, or other cover materials, HDPE's degradation rate slows dramatically. Leading research (e.g., from Queen's University) supports a potential service life well over 100 years in these ideal conditions. This makes it ideal for landfills, reservoirs, and foundational waterproofing.

- Exposed Installations: When left exposed to direct sunlight, a standard black HDPE geomembrane relies entirely on its carbon black and antioxidant package for protection. While still durable, its lifespan is significantly shortened to a range of 20-30 years due to accelerated UV degradation and oxidation.

What environmental or installation factors can affect the lifespan of HDPE liners?

Even the highest-quality geomembrane can fail prematurely if installed in a hostile environment or with poor workmanship. Identifying these risks upfront is key to ensuring long-term performance.

The most damaging factors are high temperatures, sustained UV radiation, and poor installation. Elevated temperatures exponentially accelerate oxidation, while UV exposure breaks down polymer chains. Installation defects like poor seams or subgrade punctures create weak points that lead to premature failure.

A liner's lifespan is not just about the material itself, but the environment it lives in and how it was placed there.

Key Factors That Reduce Lifespan:

- High Temperature: This is the single most aggressive accelerator of aging. The rate of antioxidant depletion roughly doubles with every 10°C increase in temperature. A liner in a hot desert climate will age much faster than one in a temperate region.

- UV Exposure: Constant exposure to sunlight degrades the polymer structure. While carbon black provides excellent protection, it is not infinite. Covering the liner is the best defense.

- Poor Installation: This is the most common cause of premature failure. Defects include:

- Inadequate Subgrade Preparation: Sharp rocks or debris can cause punctures.

- Poorly Welded Seams: Creates leak paths and points of stress concentration.

- Wrinkles: These can fold and crack over time due to thermal expansion and contraction.

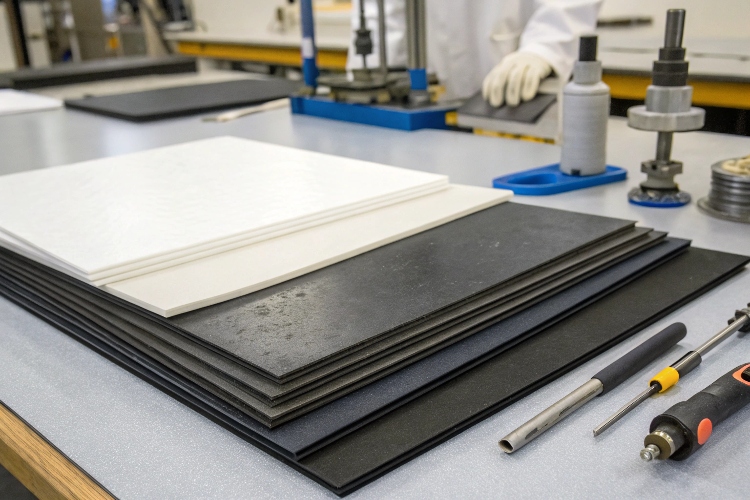

How do thickness, UV resistance, and additives influence long-term durability?

Not all HDPE geomembranes are created equal. The specific formulation and physical dimensions of the sheet you choose will have a direct and measurable impact on its durability.

Thicker geomembranes last longer by providing a larger reservoir of antioxidants and greater physical resistance to damage. Durability is further enhanced by using 100% virgin resin and a high-quality additive package, including well-dispersed carbon black (~2.5%) and specialized antioxidants.

Think of these features as an investment in a longer service life.

| Feature | Impact on Durability | What to Specify |

|---|---|---|

| Material Thickness | Increases lifespan directly. A thicker liner has more antioxidants to deplete and better resistance to punctures and wear. | For critical, long-term projects, specify at least 1.5mm (60 mil). |

| Resin Quality | Critical for performance. Virgin resin provides superior strength and stress-crack resistance. Recycled content introduces weak points. | Always demand 100% virgin HDPE resin. |

| Additive Package | Determines aging resistance. Carbon black protects against UV, while antioxidants prevent thermal degradation. Hindered Amine Light Stabilizers (HALS) offer enhanced UV protection. | Specify ~2.5% carbon black content and a robust antioxidant/HALS package compliant with GRI-GM13. |

How can I extend the service life of HDPE geomembranes in my project?

You want to maximize the return on your investment and ensure your containment system functions reliably for as long as possible. Several proactive steps can be taken during design and installation.

The most effective way to extend service life is to cover the geomembrane. Burying the liner under at least 30cm (12 inches) of soil or other material shields it from UV radiation and temperature extremes. Proper installation and the use of protective geotextiles are also crucial.

Durability is not just purchased, it is designed and built.

Best Practices for Maximizing Lifespan:

- Cover the Liner: This is the number one strategy. Shielding the geomembrane from UV light and thermal cycling is the best way to slow the aging process.

- Ensure Flawless Installation: Hire certified welding technicians. A project's longevity is only as good as its weakest seam. Implement a strict Construction Quality Assurance (CQA) plan to test every inch of the welds.

- Use a Protective Geotextile: Installing a nonwoven geotextile cushion directly beneath the geomembrane protects it from potential punctures from the subgrade, preventing long-term stress points.

- Manage Water Levels: If covering with water, ensure a minimum depth to block UV light effectively.

- Design for Drainage: Ensure proper drainage around and under the liner to prevent pressure buildup and chemical concentration.

Conclusion

Maximize your HDPE geomembrane's lifespan by burying it whenever possible. For any application, demanding high-quality virgin resin, adequate thickness, and flawless installation is the best way to ensure multi-decade performance.