HDPE Geomembrane — Manufacturer, Specifications & Project Solution

High-density polyethylene liners for environmental, water, and mining projects. Smooth or textured, 0.3–3 mm, factory-direct supply and project-specific QA.

ASTM/GRI/ISO-Reference

Factory Directly

Export Global

Excellent Properties of HDPE Geomembrane

HDPE geomembrane is a flexible waterproof liner with a very low permeability coefficient (≤1×10⁻¹⁷ cm/s), making it ideal for pond liners, dams, and landfill lining.

Suitable for extreme conditions, HDPE geomembrane performs reliably from -70℃ to 110℃, ensuring stability in hot deserts and cold climates.

Resistant to acids, alkalis, oils, and industrial effluents, HDPE geomembrane is widely used in mining leach pads, wastewater treatment, and chemical containment.

With excellent tensile properties, HDPE geomembrane sheets and rolls meet demanding engineering standards for durability and safety.

Outstanding anti-aging performance allows long-term exposed use without losing mechanical strength, suitable for reservoirs, canals, and slope protection.

High tensile strength and elongation enable HDPE geomembrane liners to withstand differential settlement, seismic zones, and harsh geological environments.

Made from ≥97% virgin HDPE resin with carbon black, free of additives or harmful stabilizers. HDPE is approved in many countries as a safe packaging material.

Get to Know HDPE Geomembrane

HDPE geomembrane is a waterproof liner made from high-density polyethylene, designed to prevent seepage in ponds, landfills, dams, and other containment projects.

It is produced from virgin HDPE resin with carbon black, UV stabilizers, and antioxidants, ensuring strength, flexibility, and long-term durability against weathering and chemicals.

Typical HDPE geomembrane thickness ranges from 0.3 mm to 3.0 mm. Lighter grades suit ponds and canals, while thicker liners serve landfills and mining sites.

Yes. HDPE geomembrane has an extremely low permeability coefficient, making it fully waterproof for ponds, reservoirs, and leachate control in landfills and mining facilities.

HDPE geomembrane liners are widely applied across multiple industries:

Environmental & Sanitation – landfill liners, wastewater treatment, hazardous waste storage, chemical warehouses, industrial waste, and construction or demolition debris containment.

Water Conservancy – seepage control and reinforcement for rivers, lakes, reservoirs, dams, canals, cutoff walls, and slope protection.

Municipal Engineering – metro tunnels, underground structures, rooftop water tanks, green roof gardens, and sewer pipe lining.

Landscaping – artificial lakes, decorative ponds, golf course water features, and slope protection.

Petrochemical – chemical plants, refineries, fuel tank bases, reaction tanks, sedimentation ponds, and secondary containment.

Mining – heap leach pads, tailings dams, settling ponds, slurry storage, and mining waste containment.

Agriculture – irrigation canals, reservoirs, drinking water tanks, and farm water storage ponds.

Aquaculture – fish ponds, shrimp farms, and coastal aquaculture slope protection.

Salt Industry – salt crystallization ponds, brine ponds, and salt pool covers.

HDPE geomembrane can last 20–30 years or more, depending on thickness, UV exposure, and site conditions, making it a cost-effective long-term containment solution.

Surface Types & Color Options of HDPE Geomembrane

Double-Smooth HDPE Geomembrane

Manufactured from high-quality virgin polyethylene with ~2.5% carbon black, antioxidants, and UV stabilizers through a co-extrusion process. It offers excellent aging resistance and impermeability. In underground applications such as aquaculture ponds, swimming pools, or leachate tanks, its service life can reach 20–50 years. When used as exposed capping layers, lifespan is typically shorter, about 5–10 years depending on UV exposure.

Double-Textured HDPE Geomembrane

This type features rough surfaces on both sides, increasing friction with soil or geotextiles, which is critical for slope stability in landfills and mining pads. Its chemical resistance and UV performance are similar to double-smooth liners, with a service life of 50–70 years under normal conditions. In harsh climates (high UV, extreme heat, or chemical exposure),lifespan may be reduced.

Rough-Surfaced HDPE Geomembrane (Single or Double)

Rough geomembranes are designed to provide higher interface friction, making them ideal for steep slopes, landfill sidewalls, or projects requiring soil cover and secondary geotextile installation. With proper installation and protection, their expected lifespan also exceeds 50 years, though sharp objects, continuous exposure, or poor maintenance can shorten durability.

Black HDPE Geomembrane

The most widely used type, made by adding carbon black during production. It offers excellent UV resistance and durability. Commonly applied in landfills, aquaculture ponds, wastewater treatment, and dam lining projects.

White HDPE Geomembrane

Produced from pure virgin HDPE resin without color masterbatch or recycled material. The white surface reflects sunlight, reduces heat absorption, and extends service life in exposed environments.

Black-Green HDPE Geomembrane

Designed with one side black and the other green. Frequently used for landfill capping systems, where the green surface improves aesthetics and mimics vegetation when viewed from above, while maintaining impermeability. treatment, and dam lining projects.

Blue HDPE Geomembrane

Manufactured from high-density polyethylene with blue coloration. It is especially suitable for swimming pools, aquariums, and decorative water facilities, providing impermeability with a visually appealing finish.

HDPE Geomembrane Thickness Guide & Applications

| Thickness (mm) | Main Performance Features | Typical Engineering Applications | Recommended Specs & Notes |

|---|---|---|---|

| 0.50 |

• Basic impermeability; lower tensile strength. • Suitable for low-stress, non-heavy-duty conditions. |

• Farm water storage ponds, irrigation canals. • Small artificial ponds, landscape water features. • Short-term or seasonal use scenarios. |

• Use on well-leveled subgrade with low risk of mechanical damage. • Add a protection layer before installation (sand bedding or nonwoven geotextile). • Expected service life: 5–10 years. |

| 0.75 |

• Improved impermeability; medium tensile strength. • Good UV and chemical resistance. |

• Aquaculture ponds. • Agricultural drainage systems. • Small leachate collection areas. |

• Can be laid directly on grass/soil subgrade. • Combine with nonwoven or protection mesh to reduce UV exposure damage. |

| 1.00 |

• Most common, best cost–performance. • Noticeably higher tensile strength and chemical resistance. |

• Small–to–medium landfill basal liners. • Industrial wastewater/ sludge ponds. • Rural drinking-water tanks, municipal channels. |

• Choose smooth HDPE geomembrane or single-textured for added friction on gentle slopes. • Service life: 15–20 years. |

| 1.20 |

• Higher puncture resistance. • Stronger chemical resistance; better stress-crack performance. |

• Medium tailings dam basal liners. • Secondary tanks in WWTPs. • Petrochemical plant containment pits. • Basement/tunnel waterproofing. |

• Use with geotextile composite to improve anti-root and anti-puncture capability. • Target GB/T 17643-2011 and GRI-GM13 compliance. |

| 1.50 |

• First choice for heavy-duty scenarios. • Tensile strength ≥ 25 MPa; ESCR ≥ 100 h. |

• Large landfill capping and side slopes. • Large tailings facility basal liners. • Chemical waste sumps. • Spillways and canal lining. |

• Prefer double-textured HDPE geomembrane to ensure slope stability. • Allow for welding overlaps and cushioning/protection layers. • Service life: 20–25 years. |

| 2.00 |

• Engineering-grade thickness with top impermeability. • Excellent puncture, chemical, and aging resistance. |

• Nuclear/ hazardous waste repositories. • Secondary containment under petrochemical storage tanks. • Large reservoirs, dam foundations. • Heavy-traffic yard subgrade containment. |

• Commonly combined with high-GSM nonwoven geotextiles. • Strict weld testing/ leak detection required. • Suitable for long-term exposed use (>25 years). |

| 2.50 – 3.00 |

• For extreme environments. • Tensile strength ≥ 30 MPa; ESCR ≥ 500 h. • Extra-long service life. |

• Special chemical/ heavy-metal residue piles. • Deep underground waterproofing. • Isolation for nuclear/ high-activity radioactive waste. • Industrial-scale tailings and heap-leach covers. |

• Often multi-layer reinforced/ composite liners. • Install by certified crews with automated welding & leak-testing equipment. • Higher budget, but life cycle can exceed 30+ years. |

HDPE Geomembrane Specifications, Testing & Data Sheet

| Property | Test Method (ref.) | Typical Value / Min | Note |

|---|---|---|---|

| Density | ASTM D1505 | ≥0.94 g/cm³ | hdpe geomembrane density |

| Tensile Properties (yield & break) | ASTM D6693 | Yield ≥ 15 kN/m Break ≥ 25 kN/m |

elongation, yield & break strength |

| Tear Resistance | ASTM D1004 | ≥ 93 N | anti-tear property |

| Puncture Resistance | ASTM D4833 | ≥ 240 N | impact & puncture resistance |

| Carbon Black Content | ASTM D4218 | 2–3% | dispersion per ASTM |

| OIT (Std / HP) | ASTM D3895 / D5885 | ≥ 100 min (Std) ≥ 400 min (HP) |

oxidative aging resistance |

| Stress Crack Resistance (NCTL) | ASTM D5397 | ≥ 500 hr | environmental stress cracking |

| Dimensional Stability | ASTM D1204 | ±2% | thermal stability |

| Permeability | ASTM (as specified) | ≤ 1.0 × 10⁻¹⁷ cm/s | hdpe geomembrane permeability |

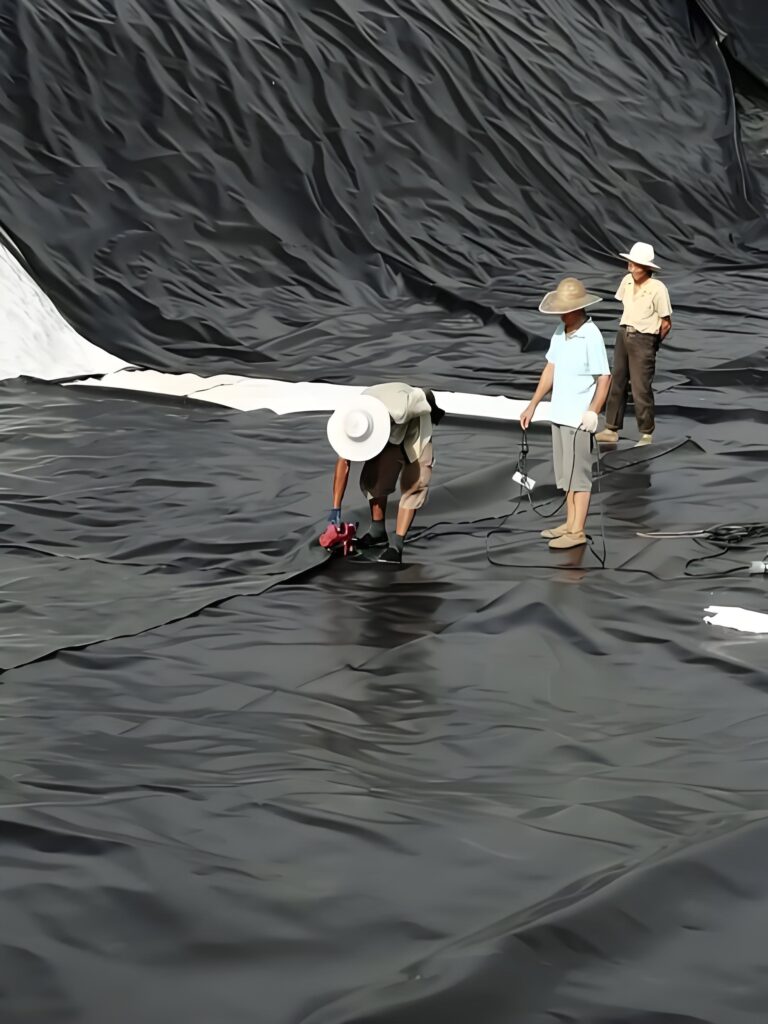

HDPE Geomembrane Installation,Welding & CQA

Welding Methods

Dual Hot-Wedge Welding: Used for production seams in HDPE geomembrane installation. Creates two parallel welds with an air channel for easy non-destructive testing.

Extrusion Welding: Applied for detail work, patches, and pipe penetrations. Uses filler rod to secure overlaps where wedge welding is not possible.

Overlap Width: Typically 100–150 mm to ensure seam integrity in both smooth and textured geomembranes.

Quality Control Procedures (CQA)

Trial Welds: Conducted daily to confirm correct temperature, pressure, and speed before full-scale seaming.

Seam Mapping: Each seam is logged and marked on project drawings for traceability.

Records: Welding logs include operator, machine ID, weather conditions, and parameter settings.

Testing Methods

Non-Destructive Tests (NDT):

Vacuum Box Test: Detects leaks in flat seams.

Air-Channel Pressure Test: Performed on dual hot-wedge seams to verify integrity.

Destructive Tests (DT):

Peel and Shear Tests: Samples are taken at defined intervals (e.g., every 150–300 m²) and tested per ASTM D6392.

Compared with LLDPE, PVC, or EVA liners, HDPE geomembrane welding requires higher precision and stricter QA. The advantage is stronger, longer-lasting seams suitable for landfills, reservoirs, and industrial containment.

Why Choose WP Specialist?

Over the years, we have established ourselves among trusted HDPE geomembrane manufacturers and global hdpe geomembrane distributors. Our focus is on delivering reliable liners that meet critical engineering projects.

- Free Samples of HDPE Geomembrane Sheet

- Expert Project Support

- Reliable Quality Assurance

- Over 10 Years of Manufacturing Experience

- Factory Direct Supply

Basics of Wholesale HDPE Geomembrane

Please include project type (pond, landfill, mining, reservoir), required thickness, surface (smooth / textured), roll size preference, and delivery terms (FOB/CIF + port).

Yes, free HDPE geomembrane sheet samples are available for evaluation prior to bulk purchase.

Typical lead time is 15–25 days for production, plus shipping schedule depending on destination port.

The standard roll width for export is 5.8 m, which is optimized for container loading. Longer widths such as 7–8 m are also available, depending on actual container loading conditions. Roll length usually ranges from 50–150 m, adjusted by thickness. Custom prefabricated panels can be supplied if required.

Weight (g/m²) = Thickness (mm) × Density (g/cm³) × 1000.

For HDPE geomembrane with density 0.94–0.96 g/cm³ (per ASTM D792), a 1.0 mm liner weighs about 940–960 g/m².

Capacity is calculated based on 40HQ ≈ 25 tons loading weight. The exact roll count depends on thickness and roll width; we calculate by the liner weight per m² and container weight limit.

The recommended minimum order is 5000 m². Since geomembrane is bulky and heavy, we suggest at least one 20GP container for efficient shipping. We can also assist in consolidating with other cargo if needed.

We are a China geomembrane manufacturer, and shipments can be arranged from any major Chinese port such as Qingdao, Shanghai, or Ningbo.

Ready to Specify a Geomembrane?

- 15+ Years of Factory-Direct Expertise

- Custom-Engineered Solutions for Your Needs

- Global Shipping & Logistics Support

- A Transparent, No-Obligation Quote

- 100% Confdentiality Guaranteed

Your email information will be kept strictly confdential and our business staff will ensurethat your private information is absolutely safe!

Contact

- info@waterproofspecialist.com

Reply within 12 hours!

Please pay attention to the email with the suffix “@waterproofspecialist.com”.