Saƙa Geotextile - Maƙera, Kayayyaki &Aikace-aikacen Injiniya

Ƙarfin polypropylene da polyester saƙa da yadudduka na geotextile don hanya, gangara, da ƙarfafa magudanar ruwa. Factory-kai tsaye wadata daga China manufacturer tare da bokan ingancin.

Fitar da Duniya

Factory Kai tsaye

Ingantaccen Inganci

Kyakkyawan Properties na Woven Geotextile

Saƙa geotextile yana ba da ƙarfi mai ƙarfi tare da ƙaramar haɓakawa, yana tabbatar da ingantaccen ƙarfafa ƙasa da rarraba kaya.

PP saƙa masana'anta yana ba da ƙarfin ƙarfi a ƙarƙashin maimaita lodi, yayin da PET filament masana'anta yana ba da juriya mai raɗaɗi na dogon lokaci don tsarin dindindin.

Tsarin yarn ɗin da aka haɗa yana ba da saƙa na geotextile na musamman na girma. Yana kiyaye sifar sa ƙarƙashin nauyi mai nauyi ko ɗaukar nauyi mai ƙarfi, yana mai da shi manufa don ƙaramar hanya da aikace-aikacen embankment.

Saƙa geotextile yadda ya kamata ya raba daban-daban na ƙasa yadudduka yayin ba da damar sarrafa ruwa gudana ta hanyar daidaitattun buɗaɗɗen ramuka.

Wannan yana hana ƙaura na ƙasa kuma yana kula da aikin magudanar ruwa na dogon lokaci a cikin hanyoyi, hanyoyin jirgin ƙasa, da bangon riƙon.

Anyi daga polypropylene inert (PP) ko polyester (PET), saƙa na geotextiles suna tsayayya da acid, alkali, da lalata ƙwayoyin cuta.

Suna kula da aikin injiniya ko da a cikin ƙasa mai gurbata ko saline.

Don aikace-aikacen fallasa ko kusa da sama, saƙan geotextiles tare da abubuwan daɗaɗɗen UV suna tsayayya da hasken rana, iskar shaka, da sauyin yanayi.

PET saƙa iri yi mafi kyau a karkashin dogon zafi da kuma hasken ultraviolet.

Kodayake yadudduka da aka saka sun yi yawa fiye da waɗanda ba a saka ba, girman pore ɗin da aka tsara (AOS) yana ba da izinin sarrafawa, daidaita tacewa da magudanar ruwa a cikin yadudduka na injiniya.

Mai sassauƙa mai ƙarfi amma mai ƙarfi, saƙa na geotextiles sun dace da saman ƙasa marasa tsari, tsayayya da huda, kuma su kasance masu tsayayye ƙarƙashin matsi na ƙasa-madaidaicin ƙasa mara daidaituwa ko ƙasa mai rauni.

Both PP and PET woven geotextiles are recyclable, non-toxic, and designed for long-term soil stabilization with minimal environmental impact.

Ku sani Woven Geotextile Fabric

Woven geotextile is a synthetic fabric made by interlacing polypropylene (PP) or polyester (PET) yarns. It provides separation, reinforcement, and filtration in roads, slopes, and drainage systems.

It is mainly used for soil stabilization, base reinforcement, embankment construction, erosion control, and filtration in civil engineering and infrastructure projects.

Common types include:

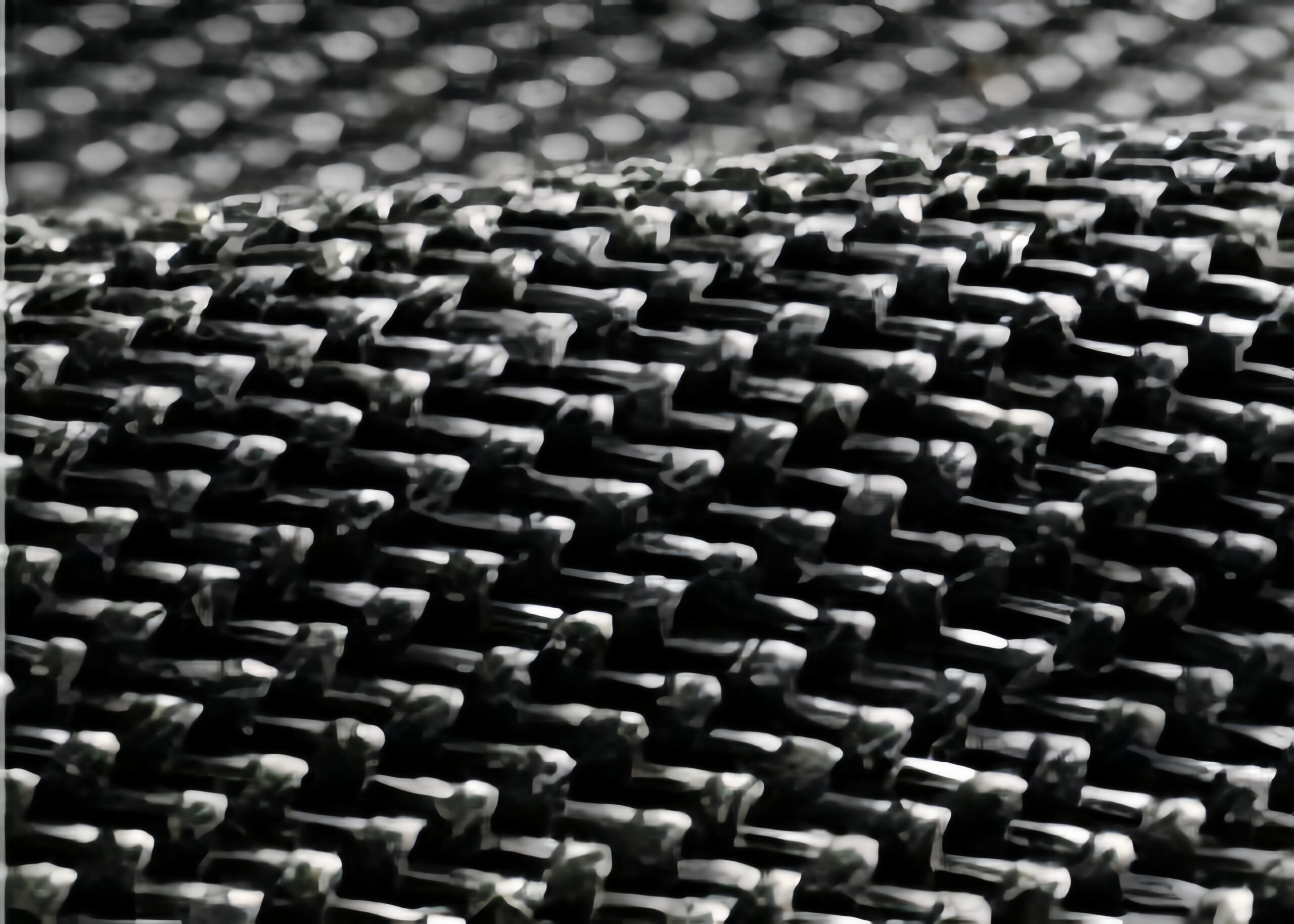

Filament Woven Geotextile (PET or PP Long-Filament) – Made from continuous polyester or polypropylene filaments. It features very high tensile strength and low elongation, ideal for long-term reinforcement in slopes, retaining walls, and embankments.

Split Yarn Woven Geotextile (PP Tape Yarn) – Produced by weaving polypropylene split-film tapes. It is cost-effective and mainly used for road base separation, stabilization, and subgrade reinforcement.

Monofilament Woven Geotextile (PP Monofilament) – Made from single polypropylene filaments with uniform pore openings, offering excellent permeability and filtration for drainage, erosion control, and riverbank protection.

Ee. HDPE geomembrane yana da ƙarancin juzu'i mai ƙarancin ƙarfi, yana mai da shi cikakken mai hana ruwa ga tafkuna, tafkunan ruwa, da sarrafa leached a cikin wuraren da ake zubar da ƙasa da wuraren hakar ma'adinai.

Ee. Saƙa geotextiles damar sarrafa ruwa kwarara ta hanyar pores da aka tsara (AOS = 0.1-0.6 mm). Su ne m amma kasa da nonwoven yadudduka, daidaita rabuwa da tacewa.

Tare da murfin ƙasa mai kyau, saƙa na geotextiles na iya dorewa sama da shekaru 50 saboda ingantacciyar sinadarai da juriya ta UV, musamman nau'ikan filament na PET.

Nau'i & Zaɓuɓɓukan kayan abu na Woven Geotextile

Bayani:

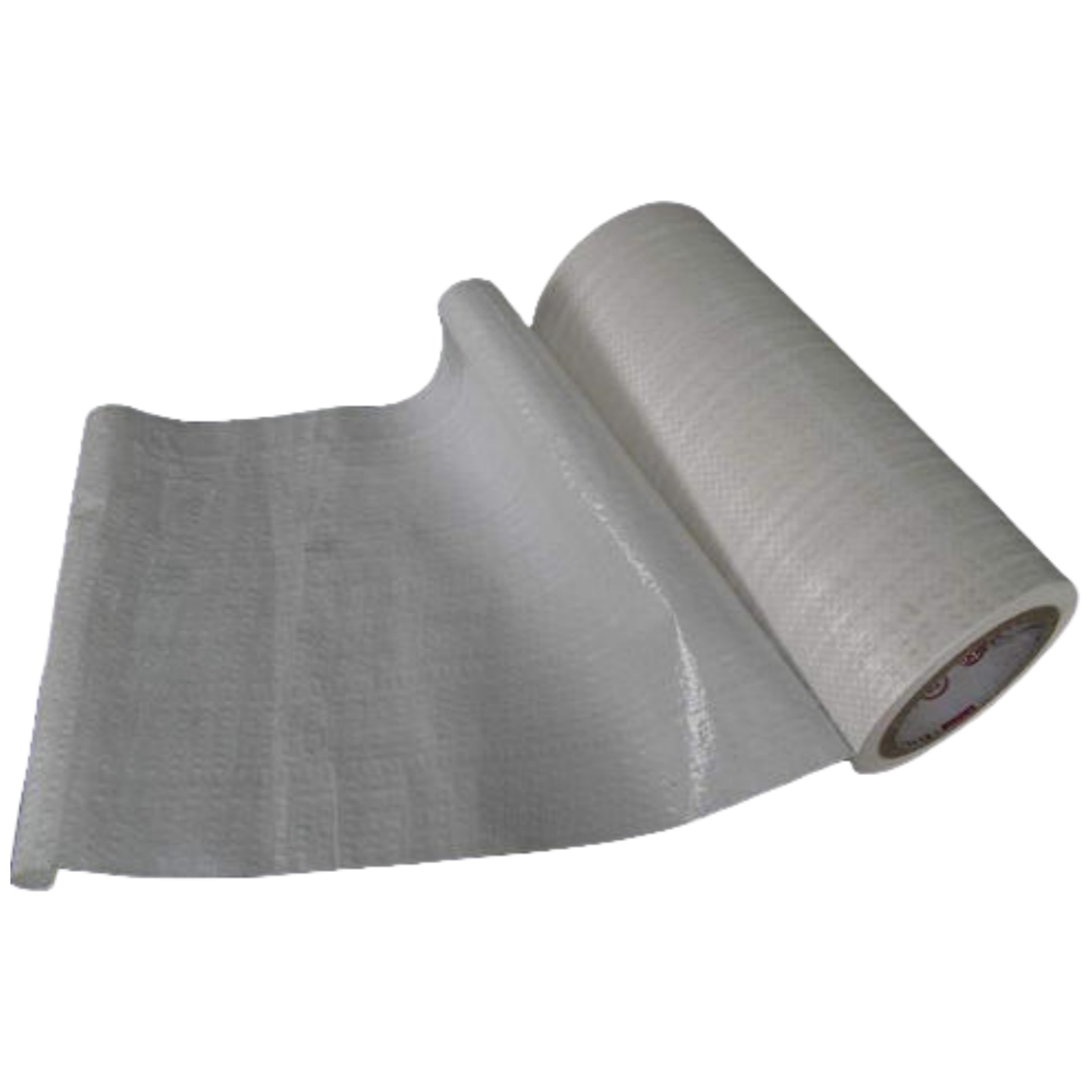

PP tsaga-yarn saƙa geotextile (kuma ake kira PP lebur yarn saƙa masana'anta) ana saƙa daga layi daya

polypropylene tef yarns a warp da saqa. Ƙaƙƙarfan tsarin saƙa na fili yana samarwa

high tensile ƙarfi, low elongation, da kyakkyawan Layer rabuwa,

making it the mainstream choice for ƙarfafa tushe tushe, Railway subgrade, da

kwanciyar hankali na ƙasa. Yana daidaita karko da tattalin arziki don manyan abubuwan more rayuwa.

Abubuwan Maɓalli:

- Ƙarfin ƙarfi mai ƙarfi (warp > sawa) da low elongation

- Tsayayyen saƙar-saƙa; rarraba kaya mai kyau da kwanciyar hankali girma

- Rabu mai inganci na ƙasa da tara yadudduka; yana rage rutsi

- Sarrafa lalacewa; yana riƙe tara tara yayin barin ruwa ya wuce

- Mai nauyi, mai ɗorewa, sauƙin kulawa; cost-effective domin taro ayyuka

Ayyuka & Aikace-aikace:

- Ƙarfafa & kwanciyar hankali don hanya / dogo subgrades da yadi

- Rabuwa tsakanin subgrade da tushe don hana intermixing

- Tanki & magudanar ruwa a cikin embankments da dandamali

- Amfani a manyan tituna, layin dogo, filayen jirgin sama, pads masana'antu, yadudduka dabaru

- Rikicin bakin teku da sarrafa yashwa tare da yadudduka na matashi

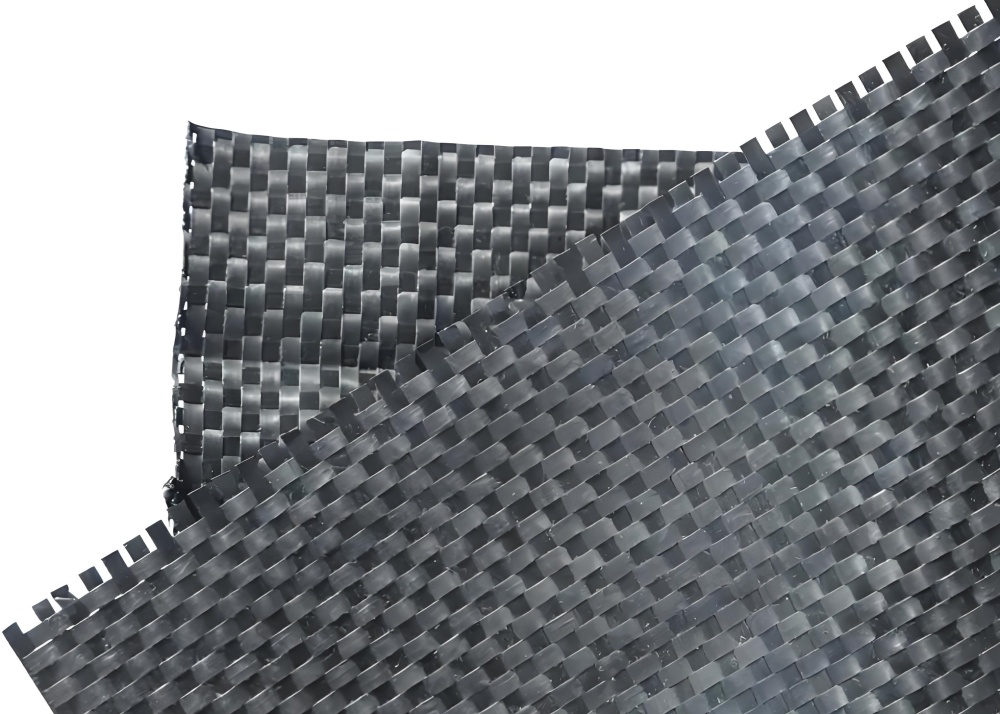

Bayani:

Filament saƙa geotextile Ana samar da shi akan faffadan looms mara motsi ta amfani da ci gaba PET ko PP dogon filaments.

It provides sosai high tensile modules, ƙananan rarrafe, da dogon lokaci karko,

critical for ƙarfafa gangara, ganuwar riƙewa, embankments,

and soft-ground improvement. With engineered pore openings, it delivers separation and filtration while

maintaining structural integrity in permanent works.

Abubuwan Maɓalli:

- Very high strength & modulus; excellent dimensional stability

- Low creep for long-service geotechnical structures

- Na kemistri & UV resistance (ASTM/ISO compliant)

- Sarrafa lalacewa; soil retention with steady flow

- Efficient logistics: light rolls, easy installation

Ayyuka & Aikace-aikace:

- Ƙarfafa of slopes, retaining walls, levees, and dams

- Rabuwa and stabilization for soft foundations

- Tanki & protection under geomembranes and liners

- Amfani a embankments, dikes, ports, bridges, airports

- Suitable for permanent civil & geotechnical projects

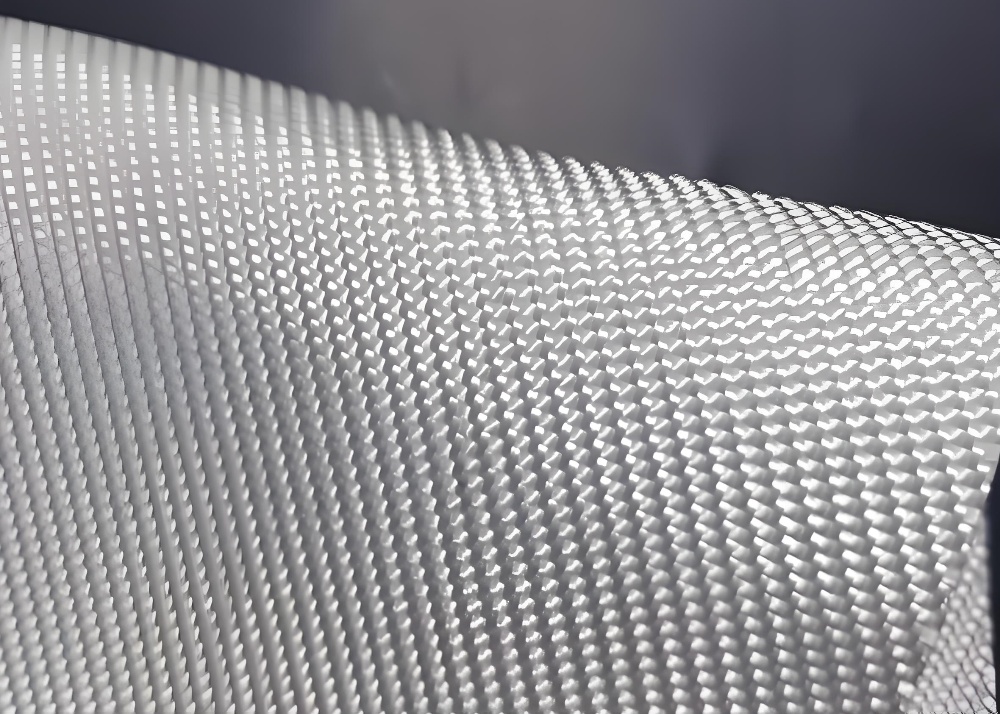

Bayani:

Monofilament woven geotextile is woven from smooth guda PP filaments, halitta

uniform pore openings da bayar high permeability da anti-clogging yi.

It combines tensile capacity with superior filtration, making it the preferred woven option for

injiniyoyin ruwa, Kariyar bakin kogi/bakin teku, da magudanar ruwa where

long-term water flow is essential.

Abubuwan Maɓalli:

- High permeability tare da ingantaccen ƙasa riƙewa

- Juriya mai toshewa da silt da biofilm ginawa

- Kyakkyawan ƙarfin ƙarfi; barga karkashin compaction

- UV & sinadaran juriya a cikin sabo ko ruwan teku

- Rayuwa mai tsawo a ƙarƙashin murfin ƙasa

Ayyuka & Aikace-aikace:

- Tanki & magudanar ruwa ga koguna, tabkuna, da tafkunan ruwa

- Kula da zaizayar kasa a kan revetments, shorelines, da gangara

- Rabuwa tare da magudanar ruwa a ciki na'ura mai aiki da karfin ruwa & harbor ayyuka

- Tafkunan ruwa da kuma kula da ruwan muhalli

- Kariyar kariya a ƙarƙashin tsarin sulke na bakin teku

Zaɓuɓɓukan gyare-gyare na Saƙa ceotextile

| Nau'in Samfur | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | Roll Width (m) | Application Range |

|---|---|---|---|---|

| Woven Geotextile — Split Yarn | 20–80 kN/m(15-56KN/M) | 75–400 g/m² (≈ 2.2–11.8 oz/yd²) | 1.0–6.0 m | Used for road base separation, subgrade stabilization, and ground improvement |

| Woven Geotextile — Filament | 35–250 kN/m | 300–950 g/m² (≈ 8.8–28 oz/yd²) | 1.0–6.0 m | For slopes, retaining walls, embankments, and long-term reinforcement |

| Woven Geotextile — Monofilament | 100–200 kN/m | 250–600 g/m² (≈ 7.4–17.7 oz/yd²) | 1.0–6.0 m | For filtration, drainage layers, and hydraulic protection works |

Typical Applications of Saƙa ceotextile

| Project Scenario | Recommended Product Type | Tensile Strength (MD/CD) | Unit Weight (g/m² · oz/yd²) | AOS (mm) | Roll Width (m) | Remarks / Key Benefit |

|---|---|---|---|---|---|---|

| Road base separation & stabilization (highways, yards) |

Split Yarn PP | 40–80 kN/m | 200–300 g/m² (≈ 5.9–8.8 oz/yd²) | 0.20–0.40 | 3.9–5.2 | High tensile with low cost; prevents intermixing and rutting |

| Soft ground or low CBR < 3% (embankments, platforms) |

Filament PET/PP | 100–150 kN/m | 250–400 g/m² (≈ 7.4–11.8 oz/yd²) | 0.15–0.30 | 4.0–6.0 | High modulus & low creep; improves long-term settlement control |

| Slopes & retaining walls (permanent reinforcement) |

Filament PET | 120–200 kN/m | 400–950 g/m² (≈ 11.8–28 oz/yd²) | 0.15–0.25 | 4.0–6.0 | Superior long-term stability under sustained load |

| Drainage & filtration layers (ditches, French drains, filter layers) |

Monofilament PP | 60–120 kN/m | 250–600 g/m² (≈ 7.4–17.7 oz/yd²) | 0.30–0.60 | 3.9–5.2 | Uniform pore openings; high permeability and anti-clogging |

| Riverbank / coastal protection (revetments, drainage, filtration) |

Monofilament PP | 80–120 kN/m | 350–600 g/m² (≈ 10.3–17.7 oz/yd²) | 0.35–0.60 | 3.9–5.2 | High flow rate; excellent durability in hydraulic environments |

Woven Geotextile Testing Standards & Performance Data Sheet

| Dukiya | Hanyar Gwaji (Ref.) | Typical Range / Requirement | Notes (for Split Yarn / Filament / Monofilament) |

|---|---|---|---|

| Tensile Strength (MD / CD) | ASTM D4595 / ISO 10319 | 40–250 kN/m | Split Yarn PP: medium strength and cost-effective; Filament PET/PP: high modulus and low creep; Monofilament PP: moderate strength with good permeability. |

| Tsawaitawa a Break | ASTM D4595 | ≤ 25% (PP) · ≤ 20% (PET) | PP types (Split/Mono) have slightly higher elongation; PET Filament provides better dimensional stability. |

| Tear Strength | ASTM D4533 | 200–800 N | Resistance to tearing and edge damage; increases with fabric density and weight. |

| CBR Puncture Strength | ASTM D6241 | 1.5–8.0 kN | Higher CBR values are recommended for heavy-duty or coarse aggregate applications. |

| Apparent Opening Size (AOS) | ASTM D4751 | 0.15–0.60 mm | Monofilament: 0.30–0.60 mm for drainage and anti-clogging; Filament: 0.15–0.30 mm for fine filtration. |

| Permittivity / Water Flow | ASTM D4491 | 0.05–0.50 s⁻¹ | Monofilament has higher permeability; Filament types have lower flow for filtration control. |

| Mass per Unit Area | ASTM D5261 | 75–950 g/m² (≈ 2.2–28 oz/yd²) | Lightweight fabrics for separation; heavyweight fabrics for reinforcement and hydraulic works. |

| UV Resistance (retained strength) | ASTM D4355 (500 h) | ≥ 70% retained | UV-stabilized grades are recommended for exposed or shallow-covered installations. |

| Ƙarfin Kafa | ASTM D4884 | ≥ 60% of fabric tensile | Seamed or stitched joints should maintain at least 60% of the parent fabric tensile strength. |

| Thickness (optional) | ASTM D5199 | 0.3–2.0 mm | Optional reference; thickness correlates with unit weight and tensile capacity. |

Woven Geotextile Installation & Quality Control (CQA)

Laying Methods

Surface Preparation:

Ensure the subgrade is smooth, compacted, and free of sharp stones or debris that may puncture the fabric. Remove any standing water before installation.Unrolling & Alignment:

Woven geotextiles are supplied in rolls and should be unrolled manually or by light machinery along the prepared surface, avoiding tension or stretching.Overlap Width:

Typical overlaps are 300–450 mm for unstitched joints. In areas requiring high load or filtration control, seams can be joined by sewing or heat-bonding depending on project specifications.Anchoring & Fixation:

Secure the fabric temporarily with sandbags, U-shaped pins, or anchor trenches to prevent wind uplift and misalignment during placement of fill materials.Backfilling & Kariya:

Place soil, aggregate, or sand carefully in layers to avoid fabric displacement. Avoid dropping materials from excessive height. Maintain uniform tension and avoid wrinkles.Connection with Other Layers:

When combined with geomembranes, drainage nets, or erosion mats, the woven geotextile should be placed beneath or above according to its function (separation, filtration, or reinforcement).

CQA Recommendations

Visual inspection before and after installation to detect damage or folds.

Overlaps and joints should comply with project specifications and test results.

Field sampling and tensile testing may be performed to verify material conformity.

Damaged areas must be cut and patched with fabric extending at least 0.3 m beyond the defect.

Me yasa Zabi WP Specialist?

Tsawon shekaru, Masana na WP has built a strong reputation as one of China’s trusted woven geotextile manufacturers and global suppliers of geosynthetic materials.

We focus on delivering reliable woven fabrics that meet the demanding needs of civil, road, and hydraulic engineering projects worldwide.

Our woven geotextiles combine high tensile strength, stability, and consistent quality — backed by factory-direct service and technical expertise.

- Free Samples of Woven Geotextile Fabric

- Taimakon Aikin Kwararru

- Tabbacin Ingantacciyar Tabbaci

- Sama da Shekaru 10 na Ƙwarewar Masana'antu

- Kayayyakin Masana'anta Kai tsaye

Ready to Specify a Geotextile?

- Shekaru 15+ na masana'antar kai tsaye

- Abincin da aka kirkira don kayan aikinta don bukatunku

- Jigilan duniya & Tallafin Lissafi

- A bayyane, babu-hari

- 100% ya tabbatar da tabbacin

Bayanin imel ɗinku za a kiyaye tsananin tabbatacce kuma ma'aikatan kasuwancinmu zasu tabbatar da bayanan sirri na sirri cikakke ne!

Hulɗa

- info@watproofspecilist.com

Amsa a cikin awanni 12!

Da fatan za a kula da imel tare da Sayad "@ @ R ratsar ruwa.