Leachat mai guba mai ƙyalƙyali na iya cutar da ruwan ƙasa, yana haifar da haɗari mai yawa da haƙƙin muhalli. Tsarin da aka ƙera na ƙasƙanci shine babban shingen injiniya wanda ke hana wannan bala'i mai yuwuwa faruwa.

Matsakaicin ƙasƙanci shine tsarin shinge na injiniya wanda aka sanya a ƙasa da kuma kusa da sharar gida don hana kamuwa da cuta. Yana da matukar mahimmanci saboda yana dauke da leach mai guba da iskar gas, yana kare ruwan karkashin kasa, kasa, da lafiyar jama'a daga gurbatar yanayi.

A matsayina na mai kaya, Na aika da kwantena masu yawa na geosynthetics don ayyukan share ƙasa a duniya. Shafukan da suka fi nasara kuma amintacce duk suna da abu ɗaya gama gari: zurfin fahimtar cewa layin a tsarin. Ba wai kawai Layer Layer Layer ba ne kawai. Yana game da shirin daidaitawa tsakanin sassa da yawa suna aiki tare. Bari mu warware ainihin abin da ke shiga cikin zamani, amintaccen matsugunin shara domin ku iya tantance aikinku na gaba da ƙarfin gwiwa.

Wadanne abubuwa ne suka hada da tsarin shimfidar shara na zamani?

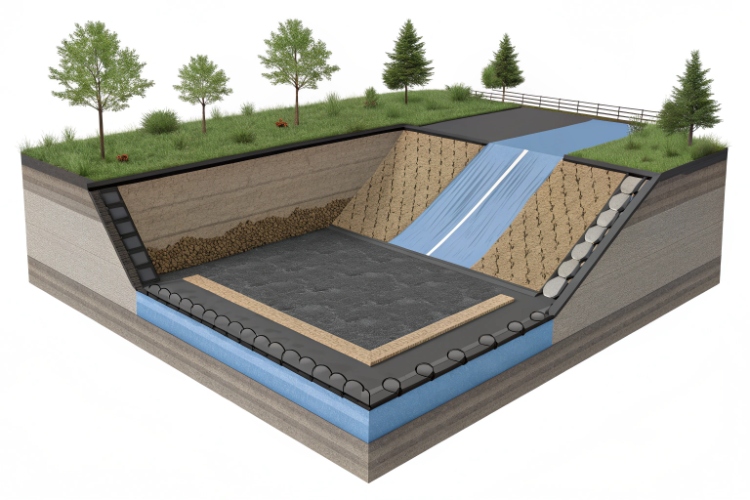

Tunanin shimfidar shara Layer ɗaya ne kawai babban kuskure, amma gama gari. Huda guda ɗaya a cikin Layer ɗaya na iya haifar da babbar matsala a ƙasa. Tsari na zamani wani tsari ne mai haɗaka tare da ɗimbin yadudduka masu yawa.

Tsarin layi na zamani ya haɗa da tushe na yumbu mai katsewa ko Geosynthetic Clay Liner (GCL), babban maɗaukakiyar Polyethylene (HDPE) geomembrane na farko, Layer matashin matashin geotextile don kariya, da magudanar ruwa (kamar geonet) don tattara leachate.

Yi la'akari da shi a matsayin ƙungiya inda kowane ɗan wasa yana da takamaiman matsayi. Daga ƙasa zuwa sama, kowane Layer yana ba da gudummawa ga cikakken tsaro na tsarin ɗaukar hoto. Daidaitaccen tsari ya dogara da ko don ƙaƙƙarfan sharar gida ne ko kuma ƙarin sharar haɗari mai haɗari, wanda sau da yawa yana buƙatar biyu-liner tsarin don ƙarin tsaro.

Anan ne kalli manyan 'yan wasa a cikin al'ada hadadden tsarin layi:

| Layer | Kayayyakin gama gari | Aikin farko |

|---|---|---|

| Rage darajar | Ƙasar ƙasa da aka shirya | Yana ba da tabbataccen tushe ga dukan tsarin. |

| Barrier Layer 2 | Compacted Clay ko GCL | Shamaki na biyu wanda ke ba da ƙarancin ƙarfi. |

| Barrier Layer 1 | HDPE ko LLDPE Geomembrane | Babban shamaki mai hana ruwa ruwa. |

| Layer na kariya | Geotextile mara saka | Cushions geomembrane daga huda daga sama. |

| Ruwan Ruwa | Geonet ko Gravel | Yana tattara kuma yana cire leach daga tsarin. |

| Tace Layer | Geotexile | Yana hana sharar gida toshe magudanar ruwa. |

Wannan tsari mai nau'i-nau'i yana haifar da sakewa. Idan Layer ɗaya ya kasance an lalata shi, sauran suna nan don samar da madadin, tabbatar da kare muhalli na dogon lokaci.

Ta yaya injin daskarewa zai hana zubar da ruwa da gurbatar ruwan karkashin kasa?

Kun ga jerin yadudduka daban-daban, amma ta yaya suke hana ruwa mai guba tserewa? Ba sihiri bane. Tsarin yana amfani da dabara mai tasiri mai ƙarfi biyu wanda ya haɗa tare da tarawa.

Tsarin layi yana aiki ta hanyar amfani da shingen da ba zai iya jurewa ba (geomembrane da yumbu) don toshe ruwa daga wucewa ta jiki. Sama da wannan shingen, tsarin tarin yana fitar da ruwa sosai, yana rage matsi da kuma hana yoyo kafin su iya faruwa.

Jigon nasarar tsarin yana cikin ayyuka daban-daban guda biyu suna aiki tare.

Aikin Katanga mara Matsala

Babban abubuwan shinge, da HDPE Geomemlane da GCL ko yumbu mai yumɓu, suna da ƙarancin ƙarancin ƙarfi. HDPE geomembrane a zahiri ba shi da ruwa, tare da ma'aunin iya aiki ƙasa da 1x10⁻¹³ m/s. Idan aka kwatanta hakan, ruwa zai ɗauki dubban shekaru kafin ya wuce ta cikinsa. Lambun yumbu da ke ƙasa yana ba da wani shinge mai ƙarancin ƙarfi. Wannan haɗin yana samar da katanga mai ƙarfi wanda leda ba zai iya wucewa kawai ba.

Ayyukan Tarin Active

Just blocking the liquid is not enough. Over time, the liquid (leachate) would build up on top of the liner, creating immense pressure known as "hydrostatic head." Wannan matsa lamba na iya tilasta ruwa ta hanyar da ba a iya gani ba ko kuma matsa lamba. Don warware wannan, a Tsarin Tari da Cire Leachate (LCRS) an shigar kai tsaye sama da shingen. Wannan magudanar ruwa, sau da yawa geonet, yana tattara leach ɗin yana busa shi don samun magani mai kyau. Ta hanyar cire ruwa akai-akai, muna ci gaba da matsa lamba akan layin da ke ƙasa da ƙarancin ƙarfi, yana haɓaka tasirin sa.

Wadanne kayan da aka fi amfani da su a cikin tsarin layi?

Ƙayyadaddun kayan aikin layi na iya zama da rikitarwa. HDPE, LLDPE, GCL, Geotextile, Geonet - wanne ya tafi ina kuma me yasa? Yin amfani da abin da bai dace ba don kowane nau'in da aka ba shi na iya yin illa ga amincin aikin gaba ɗaya da rayuwar ƙira.

Abubuwan gama gari sun haɗa da HDPE ko LLDPE geomembranes don shinge na farko, Geosynthetic Clay Liners (GCLs) a matsayin shinge na biyu, ƙirar geotextiles marasa sakawa don kariya da tacewa, da manyan geonets masu gudana don magudanar ruwa.

Kowane kayan geosynthetic an ƙera shi don takamaiman aiki. A matsayina na mai siyar da kayayyaki, aikina shine in taimaka wa abokan ciniki su zaɓi ƙayyadaddun ƙayyadaddun bayanai don kowane Layer don tabbatar da daidaito da ingantaccen tsarin. Anan ne duban kurkusa kan mahimman kayan da ayyukansu:

| Kayan abu | Ƙayyadaddun Maɓalli | Matsayinsa a Tsarin |

|---|---|---|

| HDPE/LLDPE Geomembrane | 1.5 mm zuwa 2.5 mm kauri, guduro budurwa | Shamaki na farko. Ayyukansa shine ya zama mara ƙarfi da juriya da sinadarai ga leach mai ƙarfi. |

| Geosynthetic Clay Liner (GCL) | Bentonite lãka core, >1x10m / s permeability | Kyakkyawan shinge na sakandare. Lambun bentonite yana kumbura lokacin da aka jika, yana warkar da kananun huda. |

| Geotextile mara saka | 8 oz/sy zuwa 16 oz/sy nauyi | Yana aiki azaman matashi mai kauri don kare geomembrane daga faɗuwa da abubuwa masu kaifi a cikin magudanar ruwa ko sharar gida. |

| Geonet | High transmissivity (yawan kwarara) | Gilashin filastik wanda ke haifar da buɗaɗɗen sarari don leaf ɗin don gudana cikin yardar kaina zuwa tarin bututu. |

Zaɓin kayan inganci masu inganci shine matakin farko. Misali, yin amfani da geomembrane na HDPE da aka yi daga resin budurwa tare da ingantaccen abun ciki na baƙar fata na carbon yana tabbatar da dorewar sa na dogon lokaci akan bayyanar UV da harin sinadarai.

Waɗanne abubuwa ne ke ƙayyade aikin dogon lokaci da amincin abin da ke cike da ƙasa?

Kuna iya ƙididdige mafi kyawun kayan aiki a duniya don aikin zubar da shara. Amma ƙarancin shigarwa ko rashin kulawar inganci na iya sa waɗannan kyawawan kayan ba su da amfani, ƙirƙirar bam ɗin lokaci don alhaki na gaba.

Ayyukan dogon lokaci ya dogara da abubuwa masu mahimmanci guda uku: zaɓin kayan da ya dace don sharar da ake sa ran, tabbatar da shigarwa mai inganci tare da ƙwararrun walda da QA / QC, da kuma kare layin daga lalacewa ta jiki a lokacin da bayan ginin.

An ƙera tsarin layi don ɗaukar shekaru da yawa, ko ma ƙarni. Samun cewa tsara rayuwar ba haɗari ba ne; sakamakon tsananin kulawa ne daki-daki.

Shigarwa da Tabbacin Inganci (QA/QC)

Mafi rauni na kowane layin geomembrane shine ginshiƙai inda ake haɗa nadi tare. Na taɓa samun kira game da gazawar layin layi. Mun kawo HDPE mai daraja, amma dan kwangilar ya garzaya da waldar dinkin dinkin ya tsallake gwajin QA/QC. Wani kabu mara kyaun walƙiya ya buɗe, yana lalata duka tantanin halitta. Wannan shine dalilin da ya sa ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwarar) ta ƙwararrun ƙwararrun sana'a da kuma cikakkiyar gwaji ba za su iya yin shawarwari ba. Gwaje-gwaje kamar gwajin matsa lamba na iska akan weld-track fusion welds da vacuum box test on extrusion welds sun tabbatar da kowane inci na kabu ba shi da tabbas.

Kariya daga Lalacewa

Jirgin layin ya fi rauni yayin gini. Dutsen dutse mai kaifi, kayan aiki da aka sauke, ko ma kayan aiki masu nauyi da ke tuƙi a kan wani wuri mara tsaro na iya haifar da huda. Wannan shine dalilin da ya sa lokacin farin ciki nonwoven geotextile kariya Layer koyaushe ana sanya shi a saman geomembrane kafin a sanya kowane tsakuwa ko sharar gida. Wannan sassauƙan shimfiɗar shimfiɗa yana ɗaya daga cikin mahimman saka hannun jari da za ku iya yi don tabbatar da amincin dogon lokaci na shingen farko.

Ƙarshe

Layin shara na zamani shine muhimmin saka hannun jari a cikin amincin muhalli. Ƙirar sa mai yawa, ta amfani da ingantaccen geosynthetics da ingantaccen shigarwa, yana da mahimmanci don kare ruwan ƙasa da guje wa ɗimbin farashin tsaftacewa na gaba.