Struggling to choose between geomembrane types? The wrong pond liner leads to leaks and expensive repairs. This guide clarifies which material is best for your specific project needs.

The best pond liner depends on your project: LLDPE is ideal for flexible, irregular ponds due to its superior elongation, while HDPE is better for large, engineered applications like landfills or mining ponds, offering high rigidity, chemical resistance, and long-term UV durability.

While that summary gives a quick answer, the right choice for an importer or contractor involves a deeper look at site conditions, installation costs, and long-term performance. Making an informed decision ensures you source the most cost-effective and reliable material. Let's dive into the technical details to help you choose wisely for your next project.

What are the key differences between LLDPE and HDPE geomembrane pond liners?

Choosing between these liners seems confusing since they're both polyethylene. However, their molecular structures create major performance differences that can make or break your project's success and budget.

LLDPE is highly flexible and ductile, conforming easily to uneven surfaces. In contrast, HDPE is rigid and stiff, offering greater tensile strength and chemical resistance. The primary trade-off is LLDPE's flexibility versus HDPE's structural durability and containment properties.

To make a practical sourcing decision, it's crucial to understand how these properties translate to real-world performance. A liner that is perfect for a landfill may be entirely unsuitable for a decorative farm pond. The key is to match the material's strengths to your project's specific demands.

Core Property Showdown: LLDPE vs. HDPE

Here is a direct comparison of their most important technical characteristics for any B2B buyer or project manager to consider:

| Siffar | LLDPE (Linear Low-Density Polyethylene) | HDPE (Maɗaukakiyar Polyethylene) |

|---|---|---|

| sassauci & Tsawaitawa | Excellent (up to 600%); conforms to uneven terrain | Low; stiffer and requires smooth subgrade |

| Ƙarfin Ƙarfi | Yayi kyau | Excellent; higher rigidity and strength |

| Resistance Huda[^1] | Superior, especially on rocky ground | Good, but can be brittle |

| Na kemistri & Resistance UV[^2] | Yayi kyau | Excellent; ideal for harsh chemicals and sun |

| Juriya Crack Danniya | Excellent; withstands thermal cycling & movement | Fair; more susceptible to cracking under stress |

| Installation | Easier; can be prefabricated in large panels | Difficult; requires specialized field welding |

This table clearly shows that the choice is not about which is "better" overall, but which provides the right balance of properties for your application.

How do I decide if LLDPE or HDPE is more suitable for my pond project?

Knowing the technical specs is one thing, but applying them to your actual site is critical. Choosing based on the wrong criteria can lead to installation headaches or premature failure.

Choose LLDPE for projects with irregular shapes, uneven subgrades, or expected ground settlement like farm or decorative ponds. Opt for HDPE for large, uniform projects like industrial reservoirs, landfills, or mining containment where chemical resistance and durability are paramount.

The decision ultimately comes down to a few key project variables. By evaluating your site conditions against the material properties, you can select the most cost-effective and reliable solution. Analyze the subgrade, pond geometry, and environmental exposure before placing your order.

Matching the Liner to the Application

To simplify your choice, consider these common scenarios:

For Decorative, Agricultural, or Irregular Ponds

LDDE is the clear winner here. Its superior flexibility allows it to conform perfectly to custom shapes, curves, and uneven ground without creating stress points. It better accommodates differential settlement, which is common in smaller earthworks. For small-to-medium aquaculture ponds or irrigation reservoirs where ease of installation is a factor, LLDPE is often the most practical and economical choice.

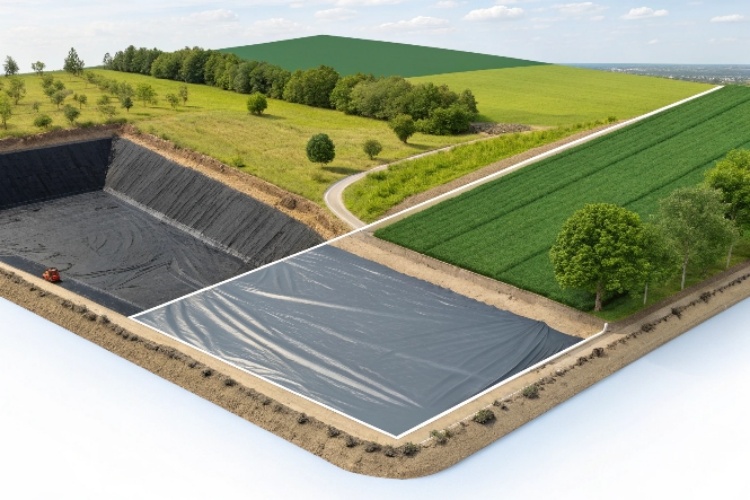

For Large, Engineered Containment Projects

Hdpe is the industry standard for applications like landfills, mining heap leach pads, and large-scale wastewater ponds. Its rigidity, high tensile strength, and exceptional chemical resistance provide the security and longevity these critical projects demand. When the subgrade is professionally prepared to be smooth and stable, HDPE offers unmatched containment performance and a lower permeability rate, protecting the environment from hazardous liquids.

What costs and installation factors should I compare between LLDPE and HDPE liners?

Focusing only on the price per square meter is a common mistake. Installation complexity and required equipment can dramatically alter the total project cost, especially for international buyers managing logistics.

While HDPE material may cost less per pound, it requires specialized hot-wedge welding machines and skilled technicians, increasing installation costs. LLDPE's flexibility allows for larger factory-prefabricated panels, which simplifies on-site work and can lower overall labor expenses significantly.

For an accurate budget, you must evaluate the "total installed cost." This includes the material, shipping, labor, equipment rental, and quality assurance testing. Miscalculating these factors can turn a seemingly affordable material into an expensive, delayed project.

Breaking Down the Total Project Cost

Consider these three cost components before finalizing your material choice:

- Farashin kayan: On a per-pound basis, HDPE is often cheaper to produce. However, LLDPE can sometimes be used in a thinner gauge for the same performance level in certain applications, which can level the material pricing. Always compare quotes for the required thickness.

- Shipping & Prefabrication: LLDPE's flexibility allows suppliers to factory-weld it into very large panels that can be folded and shipped. This drastically reduces the amount of field seaming required, saving time and money. Rigid HDPE cannot be easily folded, limiting panel sizes and increasing on-site work.

- Labor & Kayan aiki: Installing HDPE is a specialized trade. It requires certified welding technicians and expensive hot-wedge or extrusion welders to ensure seam integrity. LLDPE installation is less demanding, reducing the need for highly specialized labor and potentially lowering overall project costs, especially for smaller contractors.

Which option offers better long-term durability and reliability for my pond?

Investing in a liner is a long-term decision. Choosing a material that degrades prematurely can lead to catastrophic failure, lost revenue, and significant environmental and financial liabilities.

HDPE generally offers a longer service life (30-50 years) in stable, engineered applications due to its superior UV and chemical resistance. LLDPE is also very durable (20-30 years) and offers better reliability in conditions with ground movement or thermal stress due to its flexibility.

Durability isn't just about raw material lifespan; it's about how the material performs under your site's specific stresses over decades. The most "reliable" liner is the one whose strengths are best matched to the environmental and mechanical challenges it will face.

Factors Defining Long-Term Reliability

- UV and Chemical Exposure: For ponds with constant, direct sun exposure or those containing harsh chemicals (e.g., mining leachate, industrial wastewater), HDPE's molecular structure provides superior resistance, leading to a longer service life.

- Stress Cracking and Punctures: LLDPE is the more reliable choice in environments with thermal expansion/contraction cycles or on subgrades with rocks or roots. Its high elongation and flexibility allow it to absorb stresses and resist punctures that could cause brittle HDPE to crack over time.

- Maintenance and Repair: Both materials can be repaired, but the ease of patching is a consideration. The flexibility of LLDPE can sometimes make minor repairs simpler for on-site maintenance crews compared to the rigid nature of HDPE.

Ƙarshe

Neither LLDPE nor HDPE is universally superior. The best choice is project-specific: LLDPE for flexibility on uneven ground, and HDPE for rigid strength in large, engineered containment projects.