As the global demand for renewable energy grows, anaerobic digestion (AD) is becoming a cornerstone of sustainable waste management. But with this growth comes a critical, often underestimated project risk: containment failure. A leaking liner is not a minor maintenance issue; it is a direct threat to your environmental compliance, methane yield, and long-term operating costs.

This guide explains why biogas liner systems are a fundamental project risk decision, not just a line item on a construction budget. We will cover the core functions of these systems, the severe consequences of getting it wrong, and the key principles for selecting a robust anaerobic digestion containment solution that protects your entire investment.

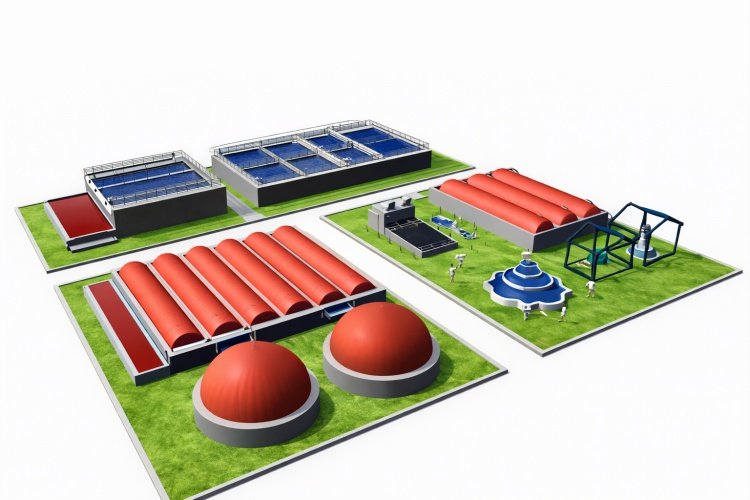

Understanding where and why these liner systems are used is the first step toward appreciating their central role in the operational and financial success of any biogas project.

1. Where Liner Systems Are Used in Anaerobic Digestion & Biogas Facilities

Geosynthetic liners are integral to nearly every part of a modern AD facility. Each application presents a unique set of mechanical and chemical challenges, meaning a "one-liner-fits-all" approach is a common and costly mistake. Here are the primary areas:

- Anaerobic Digestion Lagoons: These are the heart of the facility, where the biological process occurs. Liners form the primary containment, preventing the highly-concentrated digestate from leaking into the ground. In high-security designs, a secondary liner is often used below the primary one to create a fully contained system with leak detection capabilities.

- Digestate Storage Ponds: After digestion, the nutrient-rich liquid (digestate) must be stored safely before it can be used as agricultural fertilizer. Lined ponds prevent this high-COD liquid from contaminating soil and groundwater, a major environmental risk.

- Biogas Gas-Tight Covers: Floating covers made from flexible geomembranes are crucial for capturing the methane produced during digestion. These covers must be completely gas-tight to maximize energy yield and prevent the release of potent greenhouse gases and odorous compounds like hydrogen sulfide (H₂S).

2. Core Functions of Liner Systems in Biogas Projects

A liner system is not just a passive barrier; it is an active component performing several critical functions simultaneously. Understanding these functions highlights why the liner is an irreplaceable part of the system.

2.1 Gas Containment & Methane Loss Prevention

The primary economic output of an AD facility is biogas. Methane leakage is not just an environmental issue; it is a direct loss of revenue. A high-performance, gas-tight geomembrane is essential for maximizing energy yield. A system with poor integrity can lose a significant portion of its gas production to the atmosphere. For example, one food processing plant in Canada saw its weekly biogas collection skyrocket from negligible amounts to over 236,000 cubic feet after upgrading to a modern, high-integrity floating cover system. This directly translates to more energy produced and a faster return on investment.

2.2 Environmental Protection & Regulatory Compliance

Digestate is a highly potent organic liquid. Its Chemical Oxygen Demand (COD) can be thousands of milligrams per liter, and it's rich in nitrogen, phosphorus, and pathogens from organic waste. A liner failure can lead to severe environmental consequences:

- Groundwater Contamination: Leaked nutrients can cause eutrophication in nearby water bodies, leading to algal blooms and fish kills. The contamination of drinking water sources is a major public health risk.

- Pathogen Spread: Liners provide a physical barrier that contains pathogens like E. coli, preventing their spread into the surrounding environment.

- Regulatory Fines: Environmental agencies have stringent rules for waste containment. A leak is a clear violation that can result in heavy fines, mandatory shutdowns, and costly remediation orders. In many regions, regulations explicitly mandate double-liner systems for facilities handling hazardous or high-strength organic waste.

2.3 Chemical Resistance to Digestate & By-products

The environment inside an anaerobic digester is extremely aggressive. The biological breakdown of organic matter produces a cocktail of corrosive substances, including:

- Organic Acids (e.g., Volatile Fatty Acids)

- Ammonia (NH₃)

- Hydrogen Sulfide (H₂S)

These chemicals can quickly degrade standard construction materials like concrete and steel. High-Density Polyethylene (HDPE) geomembranes are the industry standard precisely because their molecular structure provides exceptional resistance to this chemical attack, ensuring long-term integrity where other materials would fail.

2.4 Long-Term Structural & Thermal Stability

A biogas liner system must be designed for a service life of 20-30 years or more, during which it will endure constant stress.

- Thermal Stability: Digesters often operate at elevated temperatures (35-55°C for mesophilic digestion). The liner material must maintain its strength and integrity at these temperatures. A well-designed floating cover also provides insulation, helping to maintain a stable temperature for the microbes, which improves gas production efficiency and reduces heating costs, in some cases by over 30%.

- UV Exposure: Floating covers and exposed liner sections are subject to relentless ultraviolet radiation from the sun. The geomembrane must be formulated with carbon black and an antioxidant package to prevent UV degradation, which can otherwise make the material brittle and prone to cracking.

3. Common Risks When Inadequate Liner Systems Are Used

From our experience, many failures at biogas plants are not caused by the core biological process but by a breakdown in the containment system. Using an inadequate or poorly installed liner system introduces significant operational and financial risks.

| Risk Area | Description of Failure | Direct Consequences |

|---|---|---|

| Premature Liner Degradation | Using a liner with poor chemical or UV resistance that becomes brittle and cracks over time. | Catastrophic leaks, complete system replacement required, long-term operational downtime. |

| Poor Seam Welding | Improperly welded seams that are weaker than the parent material and peel open under stress. | Methane gas leakage (revenue loss), digestate leaks (environmental fines), odor complaints from local community. |

| Insufficient Liner Thickness | A liner that is too thin to withstand hydrostatic pressure, settlement stress, or punctures. | Punctures from subgrade or equipment, tearing under load, and a significantly shortened service life. |

| Gas Pressure Buildup | Trapped gas bubbles underneath the liner due to an inadequate venting system. | Liner uplift ("whales"), high tensile stress on the liner, and potential for sudden rupture. |

| Structural Overpressure Failure | A compromised liner or blocked vent can cause gas pressure to build, leading to tank failure. | Documented cases of concrete tanks cracking and collapsing, spilling hundreds of cubic meters of digestate. |

| Toxicity and Explosion Hazard | Leaking hydrogen sulfide (H₂S) gas poses a severe health risk. Methane mixed with air is explosive. | Risk of fatal H₂S poisoning for staff and nearby residents. Explosions account for nearly 70% of biogas plant accidents. |

These are not theoretical risks. A concrete digester collapse in Europe resulted in €150,000 in direct costs and three months of lost production, all traced back to pressure issues linked to the containment system. Investing in a robust liner system upfront is a fraction of the cost of dealing with a failure.

4. How to Select the Right Liner System for Anaerobic Digestion Projects

Selecting the right liner is the most critical technical decision for ensuring long-term containment. It requires a systematic approach that considers the material, thickness, installation quality, and specific project conditions.

4.1 Material Selection

The choice of polymer is fundamental. For biogas, the primary options are HDPE and LLDPE.

| Kayan abu | Key Characteristics | Best Suited For |

|---|---|---|

| Hdpe | Rigid structure, superior broad-spectrum chemical resistance, excellent UV resistance. | Bottom liners for digesters and storage ponds where chemical resistance is paramount. |

| LDDE | More flexible, higher elongation, excellent resistance to stress cracking and punctures. | Floating covers and lining existing concrete/steel tanks with complex geometries. |

For most primary containment at the bottom of a lagoon, Hdpe is the preferred choice due to its unmatched chemical resilience. For floating covers that need to be flexible and withstand movement, LDDE is often the better solution.

4.2 Thickness & Mechanical Performance

Liner thickness is not an arbitrary number; it's an engineering decision based on the anticipated stresses. We recommend a thickness of 1.5 mm (60 mil) to 2.0 mm (80 mil) for most primary containment applications in biogas. The logic is based on resisting:

- Hydrostatic Pressure: The sheer weight of the liquid in a deep lagoon exerts constant pressure on the liner.

- Settlement Stress: Uneven ground settlement can put the liner under high tensile stress. A thicker liner provides a greater safety margin.

- Puncture Resistance: A thicker liner offers more protection against accidental punctures during installation or operation.

4.3 Installation Quality & Welding Standards

A high-quality geomembrane is useless if installed improperly. The integrity of the thousands of meters of field seams is what truly defines the system's performance.

- Certified Welders: Always use technicians certified in thermal fusion welding. Seams should be created with dual-track welders that create a testable air channel.

- Rigorous QA/QC: 100% of field seams must be non-destructively tested. This typically involves air pressure testing the channel between dual-welds and using a vacuum box on patches and extrusion welds to ensure there are absolutely no leaks.

4.4 Project-Specific Design Considerations

As a solution provider, we always tailor our recommendations based on a project's unique conditions:

- Waste Type: The specific chemical makeup of the feedstock (e.g., agricultural manure vs. industrial food waste) can influence liner material choice.

- Operating Temperature: High-temperature thermophilic digesters (>55°C) require specialized liner formulations designed for elevated temperatures.

- Climate: A site with heavy snowfall requires a more robust cover design (like a dual-membrane, air-inflated system) than one in a temperate climate.

5. Why Working with an Experienced Geomembrane Supplier Matters

Your geomembrane supplier should be more than a vendor; they should be a technical partner. An experienced supplier brings value far beyond the material itself.

- Material Consistency & Quality Control: We ensure that every roll of geomembrane delivered to your site meets or exceeds international standards (like GRI-GM13 for HDPE). This consistency is critical for reliable long-term performance.

- Technical Support During Design: We can assist your engineering team in the design phase, helping review specifications and select the optimal material and thickness to balance performance and cost.

- Custom Fabrication & Logistics Support: For complex shapes like tank liners or floating covers, we can custom-fabricate large panels in a controlled factory environment to minimize difficult field welding. Our export experience ensures reliable logistics to project sites worldwide.

- Proven Experience: Our history of successful installations in biogas and environmental projects means we understand the practical challenges and can help you avoid common pitfalls.

6. Conclusion: Liner Systems Protect the Entire Biogas Investment

A biogas liner system should not be viewed as a simple construction material or a cost to be minimized. It is the core enabling technology that protects your entire project's viability. A well-designed and properly installed liner system actively safeguards your project's environmental safety, its energy output, and ultimately, its return on investment.

Choosing the right liner system at the design stage is one of the most cost-effective risk mitigation strategies you can deploy in any anaerobic digestion project.

Frequently Asked Questions (FAQ)

1. How long do geomembrane liners last in biogas projects?

With proper material selection (e.g., UV-stabilized HDPE/LLDPE), professional installation, and protection from mechanical damage, a high-quality liner system is designed to have a service life of 20 to 40 years, often outlasting the mechanical components of the facility.

2. What thickness is recommended for a primary digester liner?

For the primary containment liner at the bottom of a digester or storage pond, we typically recommend a thickness of 1.5 mm (60 mil) to 2.0 mm (80 mil) HDPE. The final specification depends on the lagoon depth, subgrade conditions, and operational risks.

3. Are HDPE liners suitable for high-temperature (thermophilic) digestion?

Standard HDPE is suitable for mesophilic conditions (up to ~55°C). For thermophilic digesters operating at higher temperatures, special formulations of HDPE or other polymers designed for high-temperature chemical environments are required. It is critical to discuss the operating temperature with your supplier.