Tsarin layin layin geomembrane yana da ƙarfi kamar haɗin kai, kuma shigar bututu koyaushe shine mafi ƙalubale. Wannan shi ne inda wani abu mai sassauƙa (geomembrane) dole ne ya haɗu da mai ƙarfi (bututun HDPE). Haɗin da ya gaza a nan ba hanyar haɗi mai rauni ba ce; garantin gazawar duk tsarin tsarewa ne.

Wannan jagorar yana ba da cikakken tsari, mataki-mataki hanya don ƙirƙirar haɗin gwiwa mafi aminci: walda mai zafi mai narkewa ta amfani da takalmin bututu da aka riga aka kera. Za mu rufe komai daga shirye-shiryen rukunin yanar gizon da lissafin kayan aiki zuwa sigogin walda da ƙa'idodin karɓa mai inganci. Bin wannan jagorar yana tabbatar da hatimin dindindin, hatimin monolithic wanda zai dawwama tsawon rayuwar aikin.

Da farko, bari mu kafa dalilin da ya sa wannan hanyar ita ce ma'auni na masana'antu don aikace-aikacen haɗari mai girma.

Me yasa Welding Hot-Narke shine Mafi Amintaccen Hanyar Haɗi

Lokacin da aka yi daidai, walda mai zafi-narke ba kawai haɗa abubuwa biyu ba ne; yana mayar da su zuwa guda ɗaya, ci gaba. Ka'idar ita ce don ƙona kayan HDPE masu jituwa zuwa wurin narkewar su kuma ba da damar ƙwayoyin su su haɗu kafin sanyaya.

- Fusion na Kayayyaki iri ɗaya: Ta amfani da bututun HDPE, geomembrane na HDPE, da takalmin bututun HDPE da sandar walda, kuna ƙirƙirar haɗin haɗin gwiwa. Babu gaskets don ragewa ko manne don sassauta.

- Ƙarfin Weld: Daidaitaccen walda mai dacewa ya fi ƙarfin kayan iyaye da kansa. Gwaje-gwajen juriya akai-akai suna nuna walda na iya wuce kashi 90% na ƙarfin tushe, yana tabbatar da cewa zai iya jure damuwa na dogon lokaci.

- Babban Dorewa: Haɗin haɗin monolithic da aka samu yana da kyakkyawan juriya iri ɗaya ga sinadarai, UV radiation (tare da baƙar fata na carbon), da damuwa na muhalli kamar bututu na asali da layin layi.

Shiri Kafin Welding

Ana ƙaddara nasara kafin a kunna walda. Shiri mai zurfi ba za a iya sasantawa ba.

Lissafin Kayayyakin Kayayyaki da Kayan aiki

- Welders: Wutar walda ta hannu da walƙiya mai zafi mai sarrafa kansa.

- Ƙarfi: Janareta mai isassun iya aiki da ma'aunin igiyoyin tsawo daidai.

- Shirye-shiryen Surface: Angle grinder tare da 80-120 grit sandpaper m diski, mai tsabta / busassun tufafi maras lint, da sauran ƙarfi / mai tsaftacewa (kamar isopropyl barasa).

- Kayayyaki: Prefabricated HDPE bututu taya matching da bututu diamita, da HDPE extrusion waldi sanda na abu iri daya.

- Kayan Aikin Hannu: Alƙalamai masu alama, tef ɗin aunawa, wuka mai amfani, rollers na matsa lamba.

- Kayayyakin QA/QC: Tensiometer don gwajin filin, famfo iska da ma'aunin matsa lamba don gwajin tashar iska, akwatin injin motsa jiki, da na'urar daukar hoto don walda extrusion.

Bukatun Yanar Gizo

Dole ne a sarrafa yanayin walda.

- Zazzabi: Yanayin yanayi ya kamata ya kasance tsakanin 5°C da 40°C. Welding a cikin yanayin sanyi yana buƙatar preheating da shinge na wucin gadi.

- Iska: Kada aiki ya ci gaba a cikin manyan iskoki (≥25 km/h) ba tare da matsugunin kariya ba don hana saurin sanyi, rashin daidaito na walda.

- Danshi: All surfaces must be completely dry. Any moisture, dew, or frost will turn to steam during welding, creating voids and a "false weld" ba tare da karfi ba.

- Yanayin Sama: Dole ne wurin ya kasance mai tsabta kuma babu ƙura, laka, mai, da tarkace.

Mataki-mataki Tsarin walda mai zafi-Narke

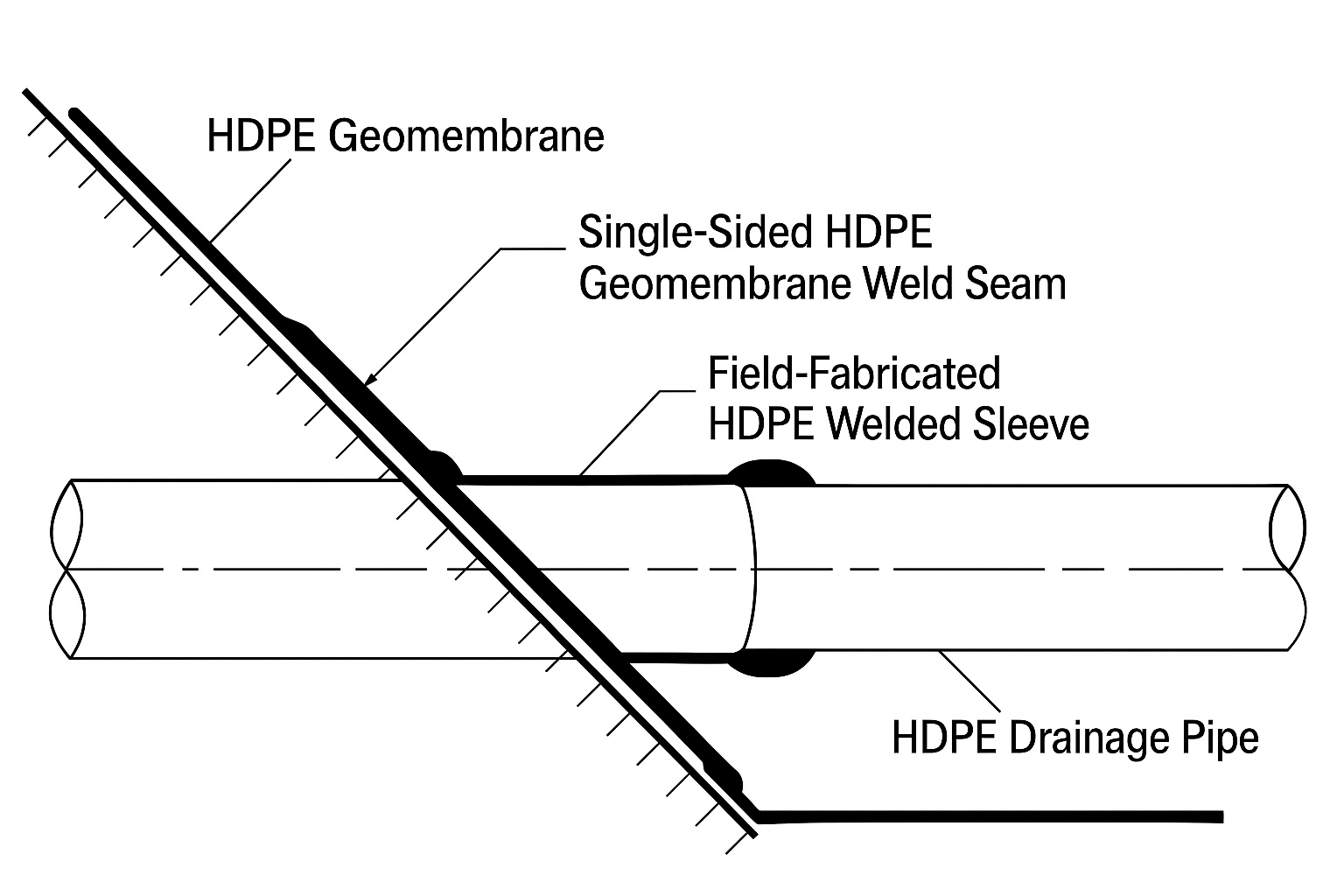

MUHIMMAN NOTE: Ba za ku iya kawai extrusion walda takardar geomembrane kai tsaye zuwa gefen bututu ba. Wannan yana haifar da matsananciyar damuwa wanda ba makawa zai gaza. Hanya madaidaiciya ita ce yin amfani da takalmin bututu da aka riga aka kera.

Mataki ①: Tsaftacewa da Niƙa saman Bututu

Weld ɗin extrusion zai haɗa zuwa waje na bututu. Yi amfani da injin niƙa na kwana don kawar da saman bututu inda hannun rigar taya zai zauna. Ci gaba da zurfi sosai don cire murfin waje mai sheki, oxidized. Manufar ita ce mai tsabta, m, matte gama. Shafa gaba dayan yankin tare da tsaftataccen busasshiyar kyalle da sauran kaushi da aka yarda don cire duk kura da mai.

Mataki ②: Yankewa da Sanya Bututu Boot

Slide the prefabricated pipe boot over the pipe. Position it so the boot's flange (or "skirt") lies flat on the main geomembrane liner with a minimum overlap of 100-150 mm (4-6 inci). Tabbatar cewa babu tazara tsakanin takalmin taya da bangon bututu. Aminta shi na ɗan lokaci a wurin.

Mataki ③: Zafi-Wedge Welding Boot Flange

Wannan matakin yana walda flange ɗin takalmin zuwa babba geomembrane liner.

- Inji: Yi amfani da waƙa biyu mai sarrafa kansa mai zafi mai walƙiya.

- Siga: Saita yanayin zafi (340-430 ° C) da gudun (1.5-3.0 m/min) dangane da kauri na kayan da yanayin yanayi, kamar yadda aka ƙaddara ta hanyar gwajin gwajin walƙiya.

- Tsari: Welder yana tafiya tsakanin geomembrane da flange na boot, yana ƙirƙirar layi ɗaya biyu fusion welds tare da tashar iska mai gwadawa a tsakanin. Wannan shi ne na farko sealing weld.

Mataki ④: Extrusion Welding Boot Sleeve

Wannan matakin yana walda ɓangaren taya a tsaye (hannun hannu) zuwa bangon bututu.

- Inji: Yi amfani da abin hannu extrusion walda.

- Siga: Saita zafin jiki na extruder don sandar walda (220-260 ° Cda zafin zafin iska mai zafi (300-330 ° C).

- Tsari: Matsa walda takalmin a wuri. Sa'an nan kuma, yi ci gaba da extrusion waldi kewaye da dukan kewaye da bututu a gindi na taya. Manufar ita ce ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan ƙaƙƙarfan robobi da aka narkar da su wanda ke haɗa abubuwan biyu. Ana ƙara wucewa ta biyu don ƙarfafawa.

Mataki ⑤: sanyaya, Kammalawa, da dubawa

Allow the welds to cool naturally. Do not use water or forced air. Once cooled, the connection is complete. Perform a full visual and physical inspection. For maximum protection, a final extrusion "cap weld" ana iya amfani da shi a saman hannun rigar taya don rufe shi da lalacewar UV da ta jiki.

Sharuɗɗan Karɓar Ingantattun walda

Dole ne a gwada kowane shigar bututu guda 100%.

- Duban gani: Welds should be continuous, smooth, and free of charring, holes, or "cold spots." Gilashin extrusion ya zama iri ɗaya kuma yana da cikakken haɗin gwiwa.

- Gwajin Tashoshin Jirgin Sama (na Hot-Wedge Weld): Rufe dukkan ƙarshen tashar iska tsakanin walda biyu. Matsa shi da iska (yawanci zuwa 30 psi / 207 kPa) da saka idanu don asarar matsa lamba. Tsayayyen matsa lamba yana tabbatar da cikakkiyar hatimi.

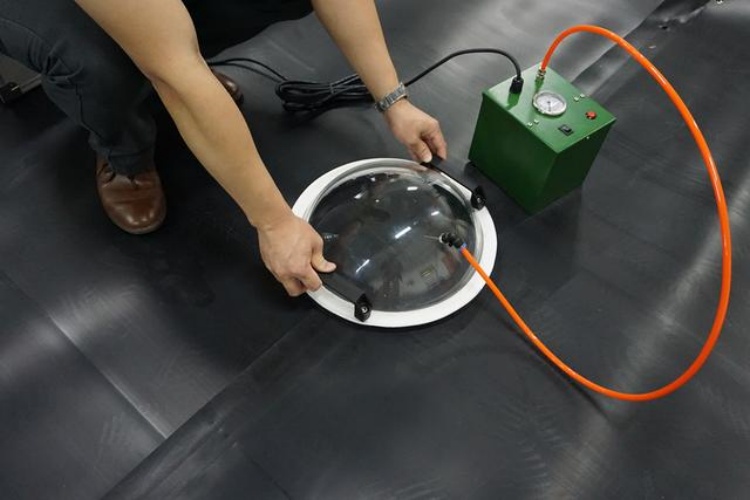

- Gwajin Akwatin Vacuum (don Extrusion Weld): Sanya akwati mai tsabta tare da bayyanannun taga akan walda. Aiwatar da maganin sabulu kuma zana injin. Samuwar kumfa yana nuna zubewa.

- Gwajin lalata: Lokaci-lokaci, dole ne a yi waldi na gwaji akan guntun kayan. Ana yanke waɗannan kuma an gwada su a cikin filin tensiometer don tabbatar da sun cika mafi ƙarancin bawo da ƙarfi da ake buƙata (yawanci. >90% na ƙarfin kayan iyaye).

Matsalolin Gina gama gari da warware matsalar

- Konewa (Ramuka): Sakamakon zafin walda mai tsayi da yawa ko kuma saurin tafiya mai saurin tafiya. Tsaya nan da nan kuma a gyara tare da faci.

- Kumfa/Babu a cikin Kabu: Wannan kusan ko da yaushe yana haifar da danshi. Fushin bai bushe gaba daya ba kafin walda. Dole ne a yanke yankin a sake yin walda.

- "Cold Weld" / Karya Weld: Weld ɗin yayi kyau amma bashi da ƙarfi kuma ana iya cire shi da hannu. Wannan yana faruwa ta rashin isasshen zafi, matsatsi mara kyau, ko ƙazanta/ gurɓataccen ƙasa. Dole ne a sake gyara duk walda.

Ƙarshe

Ƙirƙirar abin dogara, haɗin welded mai zafi mai zafi tsakanin bututun geomembrane da bututun HDPE daidaitaccen aikin injiniya ne, ba kawai matakin gini ba. Ta hanyar manne wa hanyar bututun bututu, mai da hankali kan shirye-shiryen ƙasa mai zurfi, da yin gwajin sarrafa inganci 100%, zaku iya gina haɗin gwiwa mai ƙarfi da ɗorewa kamar layin da kanta, yana tabbatar da amincin tsarin ɗaukar hoto na dogon lokaci.