Uncontrolled seepage from waste or water storage can contaminate land and groundwater, leading to massive financial and environmental liabilities. Relying on simple soil or concrete is often a failed strategy.

Geomembrane is used to create an impermeable liner or barrier for solid and liquid containment projects. Its primary function is to prevent leakage and protect soil and water resources in applications like landfills, mining, reservoirs, and wastewater lagoons.

As a key component of modern engineering, geomembrane provides a level of security and containment that traditional materials like compacted clay cannot match. Understanding its function and wide range of applications is the first step for any importer, contractor, or project manager involved in critical infrastructure or kare muhalli projects.

What is geomembrane and how does it work as an impermeable barrier?

You need a reliable barrier, but choosing the wrong material can lead to project failure. A simple plastic sheet is not an engineered containment solution, and misunderstanding the material science is a serious risk.

A geomembrane is a synthetic liner made from polymer sheets with extremely low permeability. It works by creating a continuous, non-porous barrier that physically blocks the migration of liquids and gases, effectively isolating the contained substance from the surrounding environment.

Unlike soil or concrete which are porous, geomembranes are manufactured to be virtually watertight. The material itself is one half of the system; the other is professional installation. Large panels are seamed together on-site using specialized thermal welding techniques to create a single, monolithic liner covering the entire containment area. This durable, seamless barrier is what provides long-term, reliable protection against leakage.

In which engineering and environmental projects is geomembrane most commonly used?

You know geomembrane is a versatile liner, but you may be underestimating its full range of applications. Limiting your knowledge could mean missing out on key business opportunities or specifying a less-than-optimal solution for your projects.

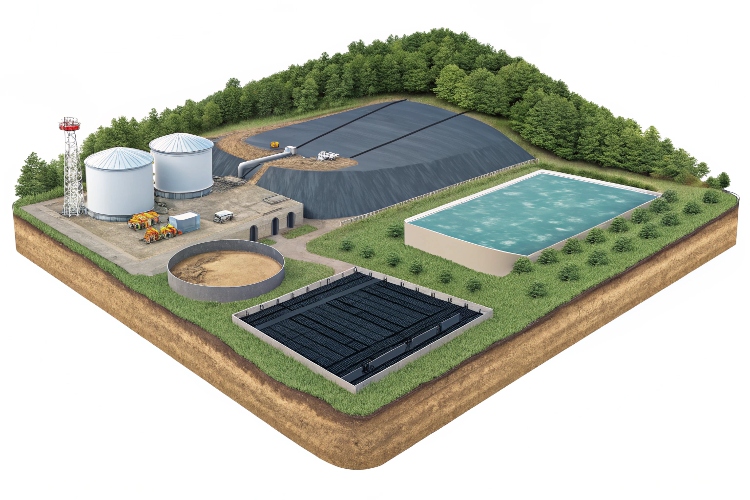

Geomembrane is most commonly used in environmental containment (landfills, caps), mining (heap leach pads), water management (reservoirs, canals), aquaculture (ponds), and industrial secondary containment. It is also used for waterproofing tunnels and basements.

The adaptability of geomembrane makes it a foundational material across numerous global industries. From protecting drinking water in a municipal reservoir to enabling mineral extraction in a mining operation, its core function of containment is critical.

Key Geomembrane Applications

| Industry Sector | Specific Application | Primary Goal |

|---|---|---|

| Environmental | Landfill liners, caps, and covers | Prevent leachate contamination of groundwater. |

| Mining | Heap leach pads and tailings ponds | Contain chemical solutions and mining waste. |

| Gudanar da Ruwa | Reservoirs, dams, canals, and ponds | Prevent water loss through seepage. |

| Noma | Aquaculture ponds and irrigation lagoons | Maintain water quality and conserve water. |

| Industrial | Secondary containment for chemical tanks | Capture accidental spills and prevent pollution. |

| Civil Engineering | Waterproofing tunnels, basements, and structures | Block groundwater intrusion. |

How does geomembrane help prevent leakage, contamination, and seepage?

Leakage is the number one risk in any containment project. Even a small, undetected leak can result in significant environmental damage, regulatory fines, and costly remediation efforts that undo a project's viability.

Geomembrane prevents leakage through a combination of its inherent impermeability and the creation of a continuous, welded system. This monolithic barrier physically stops fluid from passing through, effectively containing all liquids and dissolved contaminants.

The system's effectiveness relies on three core principles. First, the polymer material itself has an extremely low permeability rate, far superior to natural materials like clay. Second, professional welding of the seams transforms thousands of square meters of individual panels into a single, leak-proof sheet. Third, the material is engineered for durability), resisting chemicals, UV radiation, and physical stress to ensure the barrier remains intact for decades. This robust, multi-faceted approach provides a reliable, long-term defense against seepage.

How can I choose the right type of geomembrane for my specific application?

Multiple geomembrane types exist (HDPE, LLDPE, PVC), and they are not interchangeable. Specifying the wrong polymer can lead to chemical degradation, mechanical failure, and a complete breakdown of your containment system.

Choose your geomembrane based on four key factors: chemical exposure, required flexibility, UV exposure, and project budget. HDPE is best for chemical resistance, LLDPE for flexibility, and PVC is a flexible, cost-effective option for less critical applications.

Selecting the correct material is a critical decision that balances performance with project conditions. For example, the rigidity and superior chemical resistance of HDPE make it the standard for landfills. The flexibility of LLDPE makes it ideal for conforming to uneven surfaces in settlement ponds. Understanding these trade-offs ensures you are sourcing the most effective and reliable material for your needs.

Geomembrane Selection Guide

| Kayan abu | Key Strengths | Best Applications |

|---|---|---|

| Hdpe | High chemical resistance, UV stability, strength. | Landfills, mining, exposed reservoirs, tank lining. |

| LDDE | High flexibility, elongation, puncture resistance. | Pond liners, landfill caps, areas with settlement. |

| PVC | Very flexible, lower cost, excellent for prefabrication. | Decorative ponds, canals, tunnel waterproofing. |

Ƙarshe

Geomembrane is an essential engineered material for modern containment projects. By understanding its uses and selecting the right type, you can ensure long-term, reliable protection for both infrastructure and the environment.