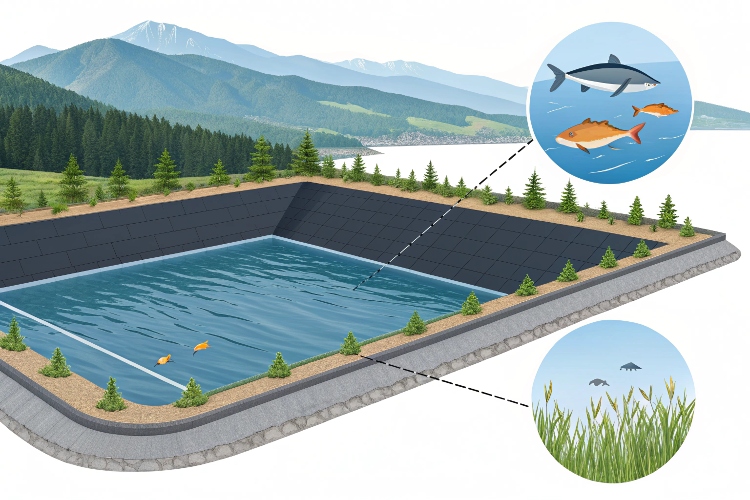

A leaking pond can ruin your aquaculture business. Poor liner choice leads to water loss, fish escape, and contamination, wiping out your profits and hard work.

For most fish farms, choose a durable, fish-safe HDPE geomembrane liner, typically 0.75mm to 1.5mm thick. Ensure it’s installed over a protective geotextile underlayment and securely welded to prevent leaks, guaranteeing a long and productive service life for your pond.

As a supplier for many large-scale aquaculture projects, I've seen firsthand how the right liner system is the foundation of a successful fish farm. It’s not just about holding water; it’s about creating a stable, safe, and efficient environment for your fish to thrive. Choosing the wrong material or cutting corners on installation will always cost you more in the long run through lost stock and constant repairs. Let’s walk through the critical decisions you need to make to get it right from the start.

What type of geomembrane liner is best for aquaculture and fish farming projects?

Using the wrong plastic can be toxic to your fish. Some materials break down under the sun or leach harmful chemicals into the water, leading to stock loss and contamination.

High-Density Polyethylene (HDPE) is the best choice. It is chemically inert, highly resistant to UV rays and biological decay from fish waste, and is certified non-toxic. Its durability makes it perfect for the demands of commercial fish farming.

Me ya sa Hdpe is the Industry Standard

When a new client asks me what to use for their fish pond, my answer is almost always HDPE. While other materials like LLDPE or EPDM exist, they don't offer the same long-term security for a commercial operation. Here's why HDPE stands out:

-

### Chemical and Biological Resistance

Fish ponds are tough environments. Fish waste and uneaten feed break down, creating organic acids that can degrade lesser materials. HDPE's stable molecular structure is highly resistant to this chemical attack. We also choose formulations with anti-algae and antibacterial additives to stop harmful growths from attaching to the liner, which keeps the pond healthier and the liner from aging prematurely. -

### UV and Weather Resistance

Most aquaculture ponds are exposed to the sun all day, every day. HDPE liners, formulated with 2-3% carbon black, are engineered to withstand decades of intense UV radiation without becoming brittle. Other materials like PVC will degrade much faster under the same conditions. -

### Fish Safety

This is non-negotiable. I only supply liners made from 100% virgin resin. This is critical because recycled materials can contain a mix of unknown plastics and additives that can leach into the water and harm or kill your fish. Virgin-grade HDPE is certified non-toxic and ensures a safe aquatic environment.

How do I select the right thickness and grade of HDPE liner for shrimp or tilapia ponds?

A liner that's too thin can be easily punctured by equipment during cleaning or by the fish themselves. This leads to leaks, costly downtime, and potential stock loss.

For smaller ponds (<1000m²), use a 0.75-1.2mm liner. For larger commercial ponds or those with bigger fish, choose a thicker 1.2-1.5mm liner to ensure superior puncture resistance and a longer service life.

Matching Thickness to Your Farm's Needs

Selecting the right thickness is a balance between cost and security. While a thicker liner is always stronger, you can optimize your choice based on the specifics of your farm.

-

Small Ponds (under 1000 m², <1.2m deep): For these applications, a 0.75mm to 1.2mm HDPE liner provides excellent protection. It’s strong enough to handle normal activity and resist punctures from cleaning tools and smaller fish.

-

Large Commercial Ponds (over 1000 m², >1.2m deep): When you have a larger operation, you have more at stake. I strongly recommend a 1.2mm to 1.5mm thick liner. This added thickness provides a much higher margin of safety against punctures from heavy equipment, worker foot traffic, and the activity of larger, more powerful fish.

Beyond thickness, you should also check the liner's technical specifications. Look for a material with high tensile strength (≥16 MPa) and excellent elongation (≥700%). This ensures the liner can stretch slightly to accommodate minor ground settlement without tearing.

What are the key steps to install a geomembrane liner correctly in a fish pond?

Poor installation is the number one cause of liner failure. Wrinkles, bad welds, and improper anchoring will create weak points that lead to leaks and costly repairs.

Proper installation involves preparing a smooth subgrade, laying a protective geotextile underlayment, securely welding all seams with a hot-wedge welder, testing every seam, and anchoring the liner's edge in a perimeter trench.

A Step-by-Step Guide to a Leak-Free Pond

Having a high-quality liner is only half the battle. As a supplier, I always emphasize that the installation quality is just as critical. Here are the essential steps my most successful clients follow:

- Site Preparation: The pond bottom must be perfectly smooth. Remove all rocks, roots, and sharp objects. Then, compact the soil and add a 5-10cm layer of sand or fine soil as a cushion.

- Geotextile Underlayment: Never lay the geomembrane directly on the soil. First, install a heavy-duty non-woven geotextile (at least 400 g/m²). This acts as a thick cushion, protecting the liner from any potential punctures from below.

- Liner Deployment: Use the widest rolls possible (our standard is 6-12m) to minimize the number of seams. Unroll the panels carefully, avoiding excessive dragging. Leave some slack in the material to allow for temperature changes.

- Seaming with a Hot-Wedge Welder: This is the most critical step. All seams must be joined using a specialized thermal fusion welder. This machine melts the two layers of HDPE together, creating a bond that is as strong as the parent material. The weld must be tested to ensure its strength is at least 80% of the liner itself.

- Anchor Trench: At the top edge of the pond, dig a trench (at least 30cm x 30cm). The liner edge is placed in this trench, which is then backfilled with compacted soil. This securely locks the liner in place.

How can I maintain and extend the lifespan of pond liners in long-term aquaculture use?

Ignoring your liner after installation is a recipe for trouble. Small damages from tools or burrowing animals can go unnoticed and develop into major, costly leaks.

Protect the liner by covering it with a 10-15cm layer of soil or smooth stones. During annual cleanings, carefully inspect the liner for any damage and repair punctures immediately with a welded patch. Avoid using sharp tools inside the pond.

Proactive Care for a Long-Lasting Pond

With the right care, a high-quality HDPE liner system can easily last 15-20 years or more. Maintenance is simple but essential.

- Add a Protective Cover: The best thing you can do for your liner is to protect it from direct impact and sunlight. After installation, cover the bottom and sides of the liner with a 10-15cm layer of soft clay or smooth, rounded stones. This shields the liner from UV rays, prevents fish from damaging it, and provides a more natural habitat.

- Conduct Annual Inspections: Whenever you drain the pond for cleaning, take the opportunity to perform a thorough visual inspection of the liner. Look carefully for any cuts, punctures, or areas that look stressed.

- Immediate Repairs: If you find any damage, no matter how small, repair it immediately. A small puncture today can become a major leak tomorrow. Use a piece of the same liner material and a hand-held extrusion welder or hot-air gun to apply a permanent, watertight patch.

- Careful Cleaning Practices: When cleaning the pond, never use sharp tools like metal shovels or sharp rakes that could cut the liner. Use soft brooms, squeegees, or high-pressure water hoses instead.

Ƙarshe

Choose a thick, virgin-grade HDPE liner and install it professionally over a geotextile. Cover and maintain it properly, and your fish pond will remain a secure, productive asset for decades.