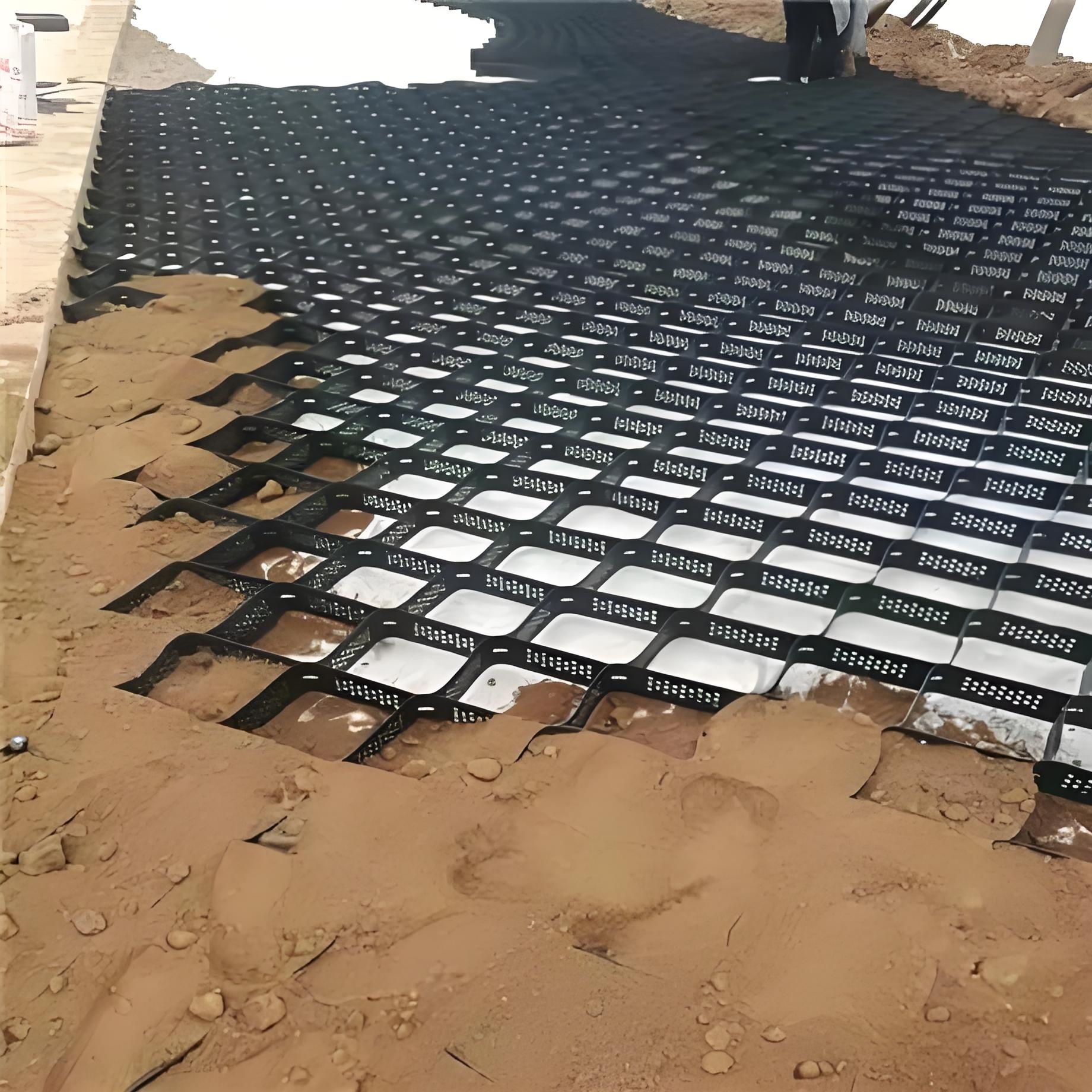

Kuna saka hannun jari a cikin tsarin geocell, kuna tsammanin zai šauki tsawon shekaru da yawa. Amma kuna damuwa cewa rana, ruwan sama, da ƙanƙara za su sa shi ya fashe kuma ya kasa, ya mai da maganin ku na dogon lokaci zuwa ɓarna mai tsada.

Kyakkyawan geocell HDPE mai inganci na iya samun rayuwar sabis sama da shekaru 50, tare da wasu ƙira suna ɗaukar shekaru 100. Wannan tsayin daka ya dogara gaba ɗaya akan amfani da guduro budurci, daidaitawar UV mai dacewa, da kare shi daga faɗuwar rana, musamman lokacin shigarwa.

A matsayina na mai samar da geosynthetics, sau da yawa ina gaya wa abokan ciniki su yi tunanin tsawon rayuwar geocell a sassa biyu: yuwuwar rayuwar sa da ainihin rayuwar sa. Yiwuwar, dangane da babban ingancin kayan HDPE, yana da tsayi mai ban mamaki. Amma ainihin rayuwar da za ku samu an ƙayyade ta yadda za ku kāre ta daga abokan gabanta—hasken rana, matsanancin zafin jiki, da damuwa. Fahimtar waɗannan abubuwan shine mabuɗin don tabbatar da cewa aikinku ya dawwama na tsararraki, ba kawai 'yan yanayi ba.

Wadanne abubuwa ne abubuwa da tsarin ke shafar rayuwar sabis na dogon lokaci na geocells?

Kuna iya tunanin duk geocells iri ɗaya ne, amma zaɓi ɗaya bisa farashi kawai babban haɗari ne. Abubuwan da ke cikin wannan baƙar fata na iya bambanta sosai, kuma shine babban al'amari na tsawon lokacin da zai ɗora.

Abubuwa biyu mafi mahimmancin ƙayyadaddun rayuwar sabis na geocell sune ingancin resin HDPE da ingancin fakitin daidaitawar UV. Komai na biyu ne ga wadannan maki biyu.

Lokacin da ka kalli geocell, ba za ka iya ganin ingancin guduro ko adadin kariya ta UV ba. Amma waɗannan abubuwan ɓoye sune ke raba samfurin shekaru 50 da na shekara 10. Ga abin da koyaushe nake gaya wa masu siya na B2B su mai da hankali akai.

Muhimman Matsayin Budurwa HDPE Resin

The term "HDPE" na iya zama mai ɓatarwa. Ana iya yin geocell daga sabon 100%, resin budurwa, ko kuma ana iya yin ta daga filastik da aka sake fa'ida. Wannan shine babban bambanci guda ɗaya a cikin inganci. Geocells da aka yi daga kayan da aka sake fa'ida suna da ƙazanta da rashin daidaituwa a tsarinsu na ƙwayoyin cuta. Wannan yana sa su zama masu rauni sosai ga Cracking Stress na Muhalli (ESC), wanda shine lokacin da robobin ke fashewa a ƙarƙashin tashin hankali na dogon lokaci. Geocells masu inganci waɗanda aka yi daga resin budurwa 100% suna da kyakkyawan juriya ga wannan, wanda shine dalilin da ya sa suka daɗe.

Tsayar da UV Ba Ne Negotiable

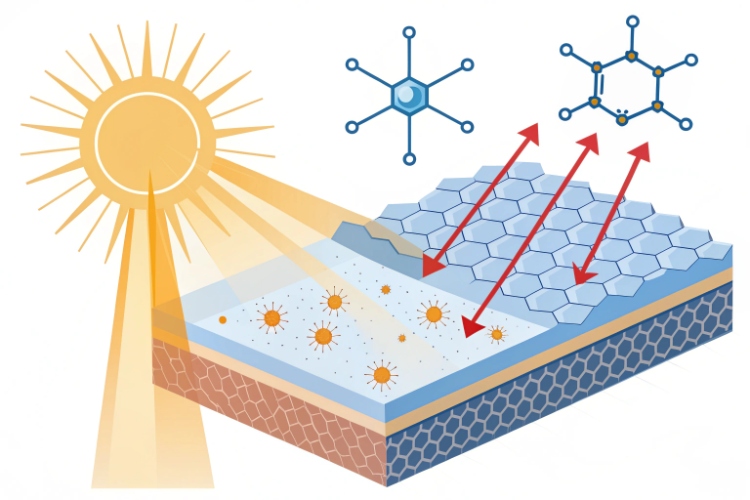

Babban abokin gaba na geocell a cikin waje shine hasken ultraviolet (UV) daga rana. HDPE mara kariya zai zama gagara kuma ya rasa fiye da rabin ƙarfinsa cikin ƴan shekaru. Don hana wannan, masana'antun suna ƙara kariya. Hanyar da ta fi kowa kuma mai tasiri ita ce ƙara 2.5% zuwa 3.5% na baƙar fata mai tarwatsewa mai kyau. Wannan yana aiki kamar dindindin, ginannen shingen rana. Don matsananciyar yanayi, ana kuma ƙara masu hana hasken amine haske (HALS). Idan ba tare da wannan fakitin kariya ba, geocell ba shi da damar cimma tsawon rayuwar sabis a waje.

Ta yaya bayyanar UV, bambancin zafin jiki, da damuwa na muhalli ke shafar dorewar geocells?

Geocell yayi kama da zama mai tsauri akan pallet, amma daga lokacin da aka shigar dashi, mahallin yana fara kai hari marar ƙarfi. Rana, ƙanƙara, da sinadarai na ƙasa duk suna aiki don rushe shi cikin lokaci.

UV radiation ne na farko tsufa factor, kai tsaye rushe polymer. Daskare-narkewar hawan keke da bayyanar sinadarai suna haɓaka wannan lalacewa, mai yuwuwar rage rayuwar sabis da ake tsammanin da kashi 30-50% a cikin yanayi mara kyau.

Fahimtar yadda waɗannan sojojin muhalli ke aiki yana ba ku damar tsarawa da shigar da tsarin ta hanyar da ta rage tasirin su.

Bayyanar Rana: Babban Mai Laifi

UV radiation daga rana shine abin da ya fi cutarwa ga fallewar geocell. Wannan yana da mahimmanci musamman a lokacin aikin ginin. Na ga ayyukan da aka bar geocells ba a gano su ba har tsawon watanni kafin a cika su. Wannan bayyanarwar farko tana da matuƙar ɓarna. Kawai watanni 3 zuwa 6 na hasken rana kai tsaye kafin binnewa na iya ragewa zuwa kashi 30% na masu gyara UV. Wannan yana rage jimlar rayuwar ƙirar geocell har tsawon shekaru 15 zuwa 25. Wannan shine dalilin da ya sa yana da mahimmanci a rufe geocells tare da kayan cika su da sauri.

Zazzabi da Damuwar Jiki

A cikin yanayin sanyi, sake zagayowar daskare-narkewar ke haifar da haɓakar geocell da shigarta. Wannan motsi na yau da kullun yana sanya damuwa na jiki akan kayan kuma yana iya hanzarta samuwar microcracks. A cikin yanayin zafi, yawan zafin jiki (sama da 50 ° C) na iya ninka adadin oxidation, wanda shine wani tsarin tsufa na sinadarai. Lokacin da kuka haɗu da waɗannan sauye-sauyen zafin jiki tare da tashin hankali daga riƙe da wani gangare mai tsayi, haɗarin Rage Damuwar Muhalli yana ƙaruwa sosai.

A cikin waɗanne aikace-aikacen waje ne geocells ke nuna mafi tsayin rayuwa?

Kuna iya amfani da geocells ta hanyoyi da yawa, amma aikace-aikacen kanta yana da tasiri mai yawa akan tsawon lokacin da kayan zai šauki. Makullin tsawon rai shine kariya daga abubuwa.

Geocells suna cimma iyakar rayuwar sabis ɗin su, galibi shekaru 70 ko fiye, a cikin aikace-aikacen binne kamar ƙarfafa tushen hanya. A cikin waɗannan al'amuran, murfin ƙasa yana ba da cikakkiyar kariya daga manyan abubuwan da ke haifar da lalacewa: UV radiation da oxygen.

A koyaushe ina bayyana wa abokan ciniki cewa idan kun kare geocell, zai daɗe. Anan ga kwatankwacin aikace-aikacen gama gari da tsawon rayuwarsu.

| Nau'in Aikace-aikace | Bayani | Mabuɗin Barazana | Rayuwar Sabis da ake tsammani |

|---|---|---|---|

| Ƙarfafawa da aka binne | Ana amfani da su a ƙarƙashin tituna, layin dogo, ko ginin tushe. An rufe shi da ƙasa ko tara. | Karamin Low oxygen, babu UV, kwanciyar hankali zazzabi. | 50-100+ shekaru |

| Rikowar Ƙarshen Ƙaƙwalwar bango | Ana amfani dashi azaman tushe na tushe don riƙe ganuwar. An binne shi a ƙarƙashin tsarin bango. | Ƙananan. An kare shi daga UV kai tsaye amma yana iya samun ɗan ɗanshi fallasa. | 50-80 shekaru |

| Ganyayyaki masu ciyayi | Cike da ƙasa kuma an rufe shi da ciyayi. Za a iya ɗan fallasa manyan gefuna. | Ƙananan zuwa Matsakaici. Tsire-tsire da ƙasa suna ba da kyakkyawan kariya ta UV. | 50-75 shekaru |

| Faɗakarwa Tarin Gandun Daji | Cike da tsakuwa don sarrafa yazawa. saman saman geocell yana fuskantar hasken rana. | Babban. Bayyanar UV kai tsaye kai tsaye da sauye-sauyen zafin jiki. | 20-40 shekaru |

| Channel Linings | Cike da tsakuwa ko kankare zuwa layin ramuka da tashoshi. Fitar da UV da kwararar ruwa. | Babban. Constant UV, tare da yuwuwar sinadari da lalacewar abrasion daga ruwa. | 20-40 shekaru |

Kamar yadda kake gani, bambancin yana da ban mamaki. Geocell wanda ke da shekaru 100 a ƙarƙashin hanya zai iya ɗaukar shekaru 25 kawai akan gangaren da ba a iya gani ba. Wannan shine dalilin da ya sa aikace-aikacen yana da mahimmanci don la'akari.

Ta yaya zan iya tantance ƙayyadaddun bayanan geocell don tabbatar da ingantaccen rayuwar sabis na dogon lokaci?

Ba za ku iya tantance geocell mai kyau daga mara kyau ta kallonsa kawai ba. Tabbacin yana cikin takaddar bayanan fasaha. Amma kuna buƙatar sanin waɗanne lambobi a zahiri suna da mahimmanci don tsinkayar rayuwa na dogon lokaci.

Don tabbatar da tsawon rayuwa, mayar da hankali kan mahimman bayanai guda uku: tabbatar da 100% budurwa HDPE resin, abun ciki na baƙar fata na carbon tsakanin 2.5-3.5%, da babban sakamakon gwajin Muhalli na Crack Resistance (ESCR).

Lokacin da na yi bitar ƙayyadaddun ƙirar masana'anta, Ina neman ƴan mahimman abubuwa waɗanda ke gaya mani idan an gina samfurin don ɗorewa. Anan akwai jerin abubuwan da zaku iya amfani dasu don tantance kowane geocell don amfanin waje na dogon lokaci.

Jerin Abubuwan Tattaunawa don Takaddun Taimako

- Gurorin Abu: Takaddun bayanai dole state "100% Virgin HDPE Resin." If it says "recycled content" ko bai ambaci tushen guduro ba, yi hankali sosai. Wannan shine mafi mahimmancin mahimmanci don tsayin daka don tsagewa.

- Kariyar UV: Look for a "Carbon Black Content" ƙayyadaddun bayanai. Ya kamata ya kasance cikin kewayon 2.5% zuwa 3.5%. Wannan yana tabbatar da cewa kayan yana da mahimmanci, ginannen shingen rana don tsira daga fallasa waje.

- Resistance Crack Resistance (ESCR): Wannan shine mafi mahimmancin gwajin gwaji don tsinkayar rayuwar sabis. Ma'aunin gwajin shine ASTM D5397. Don rayuwar da ake tsammani na shekaru 50 ko fiye, sakamakon yakamata ya zama mafi ƙarancin sa'o'i 500, tare da samfuran inganci galibi suna wuce sa'o'i 1,500. Ƙarƙashin ƙimar ESCR babbar tutar ja ce.

- Resistance Oxidation (OIT): Wannan gwajin (ASTM D5885) yana auna tsawon lokacin da kayan zai iya tsayayya da rushewar sinadarai daga iskar oxygen. Yana da mahimmanci ga aikace-aikacen fallasa a cikin yanayin dumi. Ƙimar OIT mafi girma tana nufin tsawon sabis.

Koyaushe tambayi mai siyarwar ku don cikakkun takaddar bayanan fasaha kuma, don manyan ayyuka, rahotannin gwajin gwaji masu zaman kansu waɗanda ke tabbatar da waɗannan ƙimar.

Ƙarshe

Don samun rayuwar sabis na shekaru 50+ daga geocells, dole ne ku kasance masu himma. Zaɓi samfurin da aka yi daga budurwa HDPE tare da ingantaccen ƙarfin UV, kuma rufe shi da kayan cikawa da sauri.