In a heap leach mining project, the geomembrane liner is the primary defense against environmental contamination and lost revenue. But what protects this multi-million dollar asset from the millions of tonnes of sharp, abrasive ore stacked on top of it? The answer is a geotextile. Choosing the right one is not a minor detail; it's a fundamental engineering decision.

Selecting the wrong geotextile can lead to a cascade of failures: a punctured geomembrane, blocked drainage systems, and ultimately, a catastrophic environmental and financial disaster. This guide will provide a clear, detailed framework for selecting the correct geotextile for your heap leach operation, moving beyond simple specifications to a risk-based engineering approach.

The Role of Geotextiles in Heap Leach Mining Projects

Before we can select a geotextile, we must first understand the critical jobs it performs within the liner system. In a heap leach pad, a geotextile is a true multi-tasker, but its primary role is to act as a bodyguard for the geomembrane.

The key functions include:

- Protection: This is the most important function in a heap leach pad. A thick, robust geotextile acts as a cushion, placed directly on top of the geomembrane, protecting it from being punctured by the sharp, angular stones of the drainage layer or the ore itself. A liner puncture negates the entire purpose of the containment system.

- Filtration: A geotextile allows liquids (the pregnant leach solution) to pass through freely while preventing fine soil or ore particles from migrating and clogging the drainage system. A clogged drainage system can create dangerous pore pressure buildup within the heap, threatening its stability.

- Separation: It serves as a barrier to prevent two different layers of material from mixing. For example, it can separate a subgrade from a drainage aggregate layer, maintaining the integrity and performance of both layers over the long term.

- Drainage: While less common for the geotextile itself, it works in concert with geonets or drainage aggregate to facilitate the flow of liquids within the plane of the material, ensuring the collected solution is efficiently transported to sump pits.

Of these, protection is the non-negotiable, primary function that drives selection for most heap leach applications.

Types of Geotextiles Used in Heap Leach Mining

There are two main families of geotextiles, and their manufacturing method dictates their performance. Understanding the difference is critical.

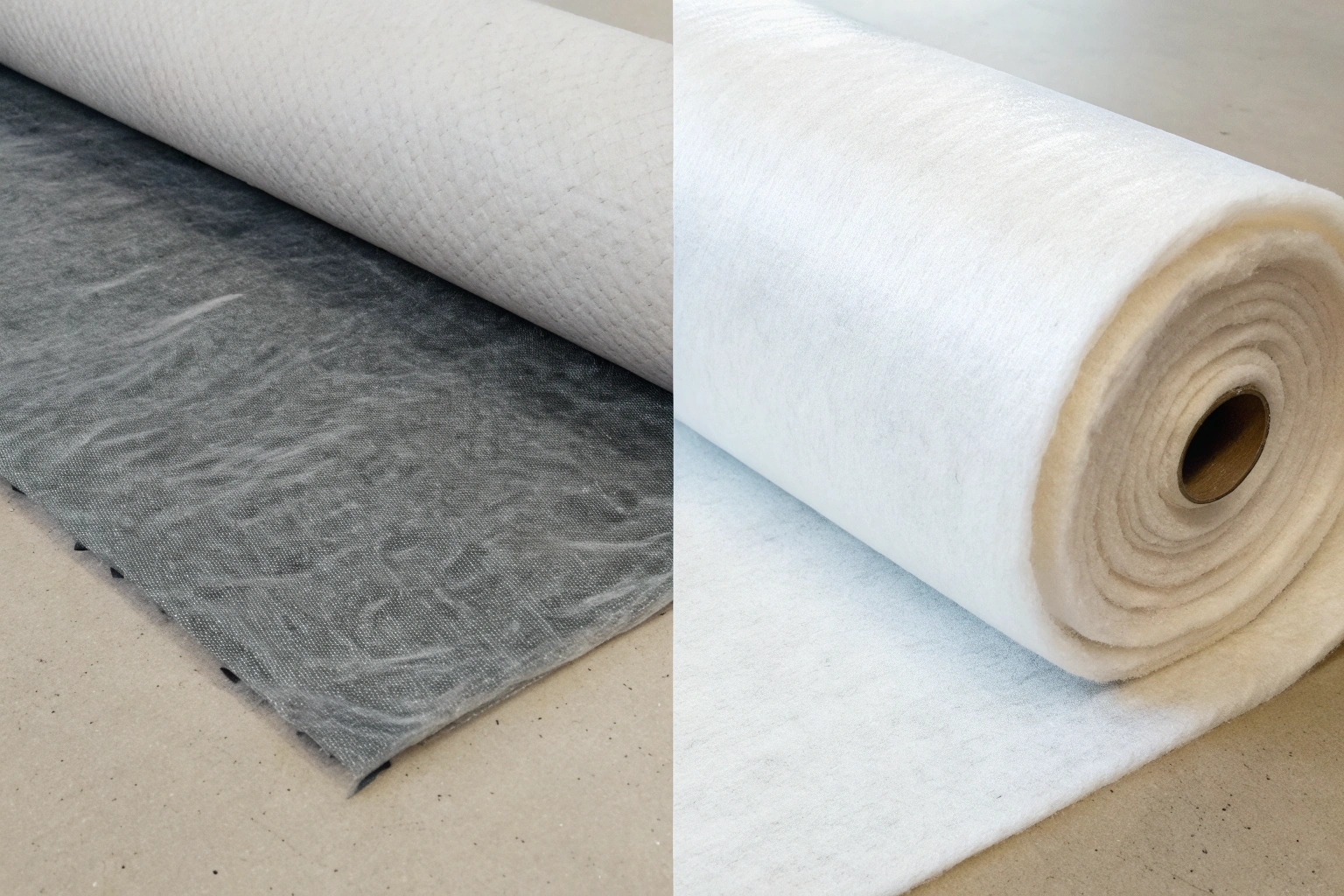

Woven Geotextile

Woven geotextiles are manufactured by interlacing threads or tapes of polymer in a traditional crisscross pattern, much like a textile fabric. This process gives them:

- Advantages: High tensile strength and low elongation. They are very strong and do not stretch much under load.

- Typical Applications: Primarily used for soil reinforcement and stabilization, such as under roads or retaining walls where high tensile modulus is needed.

Nonwoven Geotextile

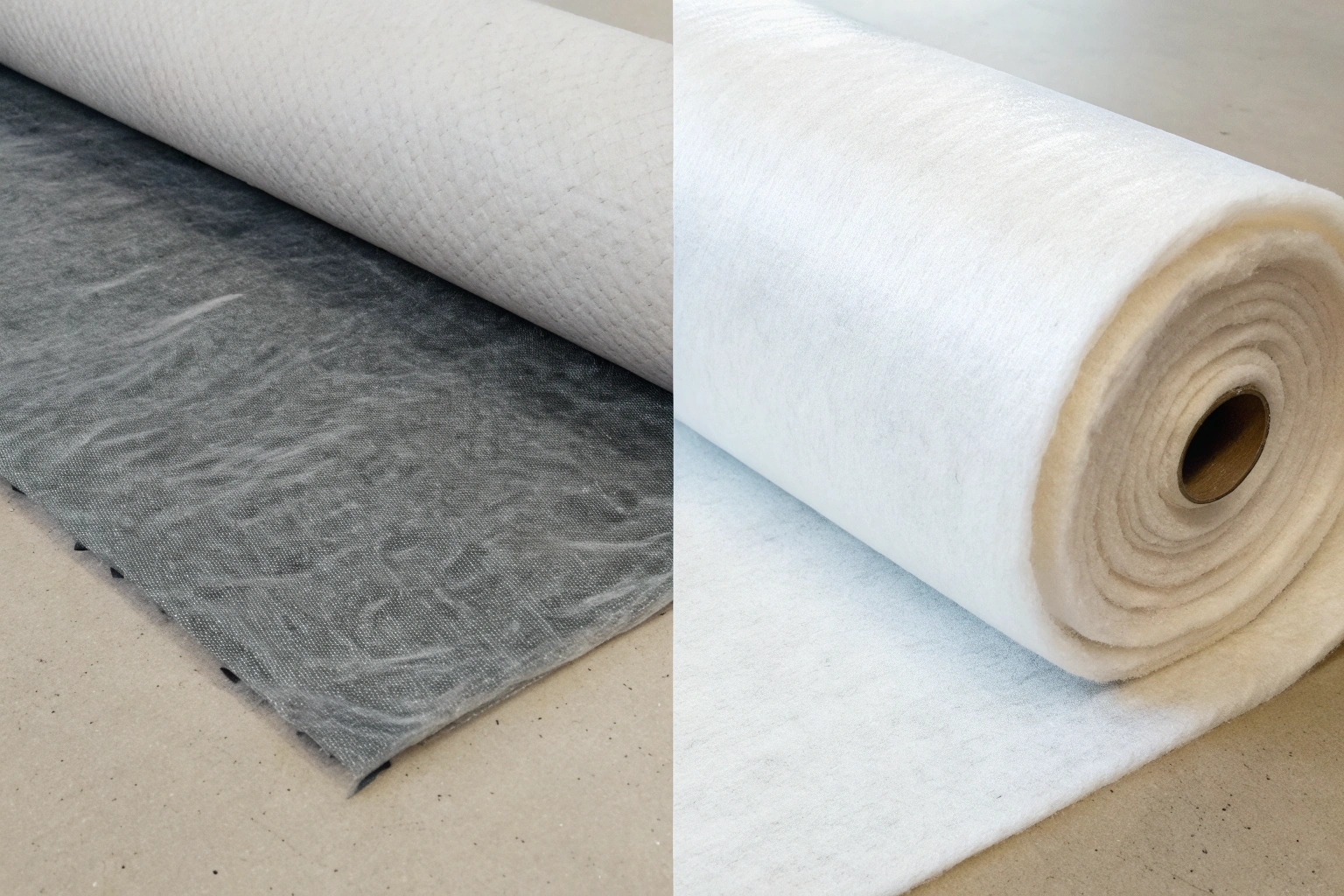

Nonwoven geotextiles are made from a web of polymer fibers that are bonded together, most commonly through a process called needle-punching. This creates a thick, felt-like material.

- Advantages: Excellent cushioning and energy absorption, superior filtration characteristics due to their three-dimensional pore structure, and high elongation.

- Common Applications: This is the go-to choice for protection, drainage, and filtration applications in environmental containment systems.

Woven vs. Nonwoven: Which Is More Suitable?

For heap leach pads, the choice is clear. While a woven geotextile is strong, it is thin and has virtually no cushioning ability. Placing a thin woven geotextile on a geomembrane is like trying to protect it from a stone with a bedsheet—it won't work.

A heavy-weight, nonwoven needle-punched geotextile is the required choice for protecting the geomembrane liner. Its thick, spongy structure is specifically designed to absorb pressure from sharp points, distribute the load, and prevent punctures.

Key Factors to Consider When Selecting Geotextiles for Heap Leach Mining

Selecting the right nonwoven geotextile involves a detailed analysis of the project's specific conditions. Here are the critical factors you must evaluate.

1. Chemical Resistance (The Go/No-Go Decision)

This is the absolute first consideration, and a mistake here is fatal. The geotextile will be saturated in an aggressive chemical solution for decades. The polymer it's made from must survive.

- Gold/Silver Mining (Alkaline Environment): Cyanide leaching is conducted at a high pH (>10). In this alkaline environment, you must use a polypropylene (PP) geotextile. Polyester (PET) geotextiles will undergo a chemical reaction called hydrolysis in a high-pH environment, causing them to lose strength and literally disintegrate over time.

- Copper/Uranium Mining (Acidic Environment): Acid leaching uses low-pH solutions (often <2). Both polypropylene (PP) and polyester (PET) have good resistance to acids. However, to simplify supply chains and eliminate any risk of accidental misuse, the industry standard is to specify polypropylene (PP) geotextiles for all mining applications.

Executive Decision: To ensure long-term performance and eliminate risk, I always recommend using only geotextiles made from 100% virgin polypropylene resin for any heap leach project.

2. Puncture Protection and Mechanical Strength

This is the primary job of the geotextile. The key is to select a product heavy and strong enough to withstand the immense pressure of the ore heap without allowing sharp stones to puncture the geomembrane. The two most important properties are:

- Mass Per Unit Area (g/m² or "GSM"): This is the weight of the geotextile and is the simplest indicator of its thickness and cushioning ability. The higher the GSM, the more protection it offers.

- CBR Puncture Resistance (kN): This is a critical laboratory test (ASTM D6241) that measures the force required to push a flat-ended plunger through the geotextile. It directly simulates the stress of a stone pushing against the liner.

Here are my field-tested rules of thumb for selecting geotextile weight based on heap height:

- Low Heaps (< 30 meters): A minimum of 540 g/m² (16 oz/yd²) PP nonwoven geotextile is recommended. This provides a solid baseline of protection for moderate loads.

- Medium to High Heaps (30 - 80 meters): You should increase the weight to a minimum of 800 g/m² (24 oz/yd²). The increased pressure requires a more robust cushion.

- Very High Heaps (> 100 meters): Standard specifications are not enough. A site-specific performance test, such as a large-scale cylinder puncture test, is required to determine the necessary protection. This often leads to specifications of 1000 g/m², 1500 g/m², or even heavier composite materials.

3. Interface Friction for Slope Stability

Heap leach pads are built on slopes to facilitate drainage. The stability of the entire ore heap depends on the friction between the different layers of the liner system. A geotextile that is too "slippery" can create a slip plane, leading to a catastrophic slope failure.

PP nonwoven geotextiles are inherently smoother than soil. Therefore, to ensure stability:

- You must use them in conjunction with a textured geomembrane. The rough surface of the textured liner interlocks with the fibers of the nonwoven geotextile, creating a very high-friction interface that can safely resist the shear forces of the ore heap.

- For any significant heap height or slope angle, a large-scale direct shear test (ASTM D5321) must be performed. This lab test measures the actual friction angle between your chosen geomembrane and geotextile under site-specific pressures, providing the data needed for a reliable slope stability analysis.

4. Filtration Properties and Clogging Risk

When a geotextile is used for filtration (e.g., to wrap a drainage pipe), its properties must be matched to the surrounding soil to prevent clogging. The key parameter is the Apparent Opening Size (AOS), which indicates the size of the pores in the fabric.

However, I issue a strong word of caution: Using geotextiles as a primary filter within the ore heap is extremely risky. The leach solution is rich in minerals and microorganisms. These can cause:

- Chemical Clogging (Scaling): Minerals (like calcium sulfate) can precipitate out of the solution and crystallize within the geotextile pores, turning it into a solid, impermeable barrier.

- Biological Clogging: Microorganisms can grow into a biofilm that clogs the fabric.

A clogged filter layer can lead to a dangerous buildup of solution within the heap, known as a "perched water table," which is a primary cause of slope instability. For this reason, sound engineering practice often specifies a carefully graded granular sand and gravel filter instead of a geotextile for critical filtration functions within a heap leach pad.

Recommended Geotextile Specifications for Heap Leach Pads

To help you in your project planning and procurement a proper specification is key, here is a summary table of recommended parameters for a protection geotextile in a heap leach pad.

| Property | Recommended Specification | Rationale |

|---|---|---|

| Polymer Type | 100% Virgin Polypropylene (PP) | Required for chemical resistance to both high-pH (cyanide) and low-pH (acid) solutions. |

| Structure | Continuous Filament Needle-Punched Nonwoven | Provides the necessary thickness for cushioning and puncture protection. |

| Mass Per Unit Area (GSM) | ≥ 540 g/m² (Standard); ≥ 800 g/m² (High Load) | Heavier weight provides greater cushioning and puncture resistance. |

| CBR Puncture Strength | ≥ 5.5 kN (for 540 g/m²); ≥ 8.0 kN (for 800 g/m²) | The primary indicator of puncture resistance and a critical mechanical property. |

| UV Resistance | Carbon Black ≥ 1.5% | Ensures the material does not degrade from sun exposure during installation. |

| Color | White or Black | White can make damage easier to spot and keeps the geomembrane cooler during installation. |

Common Geotextile Selection Mistakes in Heap Leach Mining Projects

Over the years, I've seen a few costly mistakes made repeatedly. Avoid these pitfalls:

- Selecting Based on Price Alone: Choosing a lighter, cheaper geotextile is a false economy. The cost of a liner failure will be thousands of times greater than the savings on the geotextile.

- Using a "General Purpose" Geotextile: A lightweight geotextile designed for landscaping or road separation will not survive the chemical and mechanical stresses of a heap leach pad.

- Ignoring the Chemical Environment: Specifying a PET geotextile for a gold mine is a guaranteed failure.

- Creating a Clogging Risk: Using a geotextile as a filter in a high-scaling environment without proper engineering analysis is an invitation for disaster.

How to Choose a Reliable Geotextile Supplier for Heap Leach Mining

Your supplier is your partner in risk management. A reliable supplier should offer more than just a product; they should provide confidence and support. When evaluating suppliers, ask these questions:

- Do they have proven experience with mining projects? They should understand the unique demands of heap leach pads and be able to show you relevant case studies.

- Does their product meet international standards? Look for compliance with ASTM, ISO, or GRI standards, and ask for third-party test reports to verify properties like CBR Puncture Strength and chemical resistance.

- Can they provide technical support? A good partner will work with you to review your project design and recommend the most appropriate product, rather than just selling you whatever is in stock.

Conclusion

The geotextile may seem like a simple component, but it is the unsung hero of the heap leach liner system. Its successful performance is fundamental to protecting your geomembrane, ensuring proper drainage, and maintaining the stability of the entire structure.

Proper selection is not about finding the cheapest option; it's about conducting a thorough, risk-based analysis of the chemical, mechanical, and hydraulic conditions of your specific project. By prioritizing polypropylene, specifying a heavy-weight nonwoven fabric, and verifying its performance with a reputable supplier, you are making a critical investment in the long-term safety and profitability of your mining operation.