A modern landfill liner is a complex engineered system, not just an impermeable sheet. It's a structural composite designed to withstand immense physical stress for decades. While the geomembrane provides the hydraulic barrier, it's often the geogrid that acts as the structural skeleton, providing the strength and stability to ensure the entire system performs as designed.

Geogrids are integrated into liner systems to reinforce soils, stabilize steep slopes, and absorb stresses from waste settlement, preventing catastrophic liner failure. But not all geogrids are created equal. Selecting the right one requires a deep understanding of its technical specifications. Simply choosing the "strongest" or "cheapest" option can lead to either costly over-engineering or dangerous under-performance.

This article provides a detailed guide for engineers, designers, and project managers. We will break down the critical mechanical, long-term, and durability specifications you must evaluate when selecting a geogrid for a landfill liner system. Our goal is to equip you with the knowledge to read a technical data sheet and understand how each parameter directly impacts the safety and service life of your containment facility.

Functions of Geogrids in Landfill Liner Systems

Before diving into specifications, it's essential to understand the jobs a geogrid performs within a liner system. Its functions are threefold:

- Structural Reinforcement: Geogrids act like rebar in concrete, accepting and distributing tensile loads. They strengthen the entire soil mass, increasing its bearing capacity and preventing localized failures.

- Control of Deformation and Differential Settlement: As waste decomposes, it settles unevenly. This differential settlement can place immense strain on the geomembrane, potentially stretching it to the point of rupture. A geogrid layer absorbs these strains, distributing them over a wider area and protecting the liner.

- Improvement of Slope and Interface Stability: In modern landfills with steep slopes, the geogrid is critical for preventing sliding failures. It increases the shear strength at the interfaces between different geosynthetic layers (e.g., geomembrane, GCL, geotextile) and within the soil itself, effectively "locking" the system together.

Mechanical Specifications of Geogrids

These are the primary "strength" properties you'll find on a data sheet. They describe how the geogrid behaves under short-term load.

Tensile Strength Requirements

This is the most fundamental specification. It measures the maximum load a geogrid can withstand before it breaks.

- Definition: Tensile strength is expressed in kilonewtons per meter (kN/m). It is measured in both the primary strength direction (Machine Direction, or MD) and the perpendicular direction (Cross-Machine Direction, or CD). A biaxial geogrid has similar strength in both directions, while a uniaxial geogrid has its strength concentrated primarily in the MD.

- Why it Matters: The required tensile strength is dictated by the forces the geogrid must resist. For example, a geogrid placed at the base of a landfill to absorb settlement stresses might require biaxial strengths of 50 kN/m. In contrast, a geogrid used to reinforce a very steep slope against the immense pulling force of the waste mass might require a uniaxial strength well over 100 kN/m. This specification is the first-pass indicator of a geogrid's load-bearing capacity.

Tensile Modulus and Strain Behavior

Modulus is a measure of a material's stiffness. It describes the relationship between stress (load) and strain (elongation).

- Definition: Tensile Modulus is calculated from the load at a specific, low level of strain, typically 2% or 5%. A high modulus means the material is very stiff—it carries a high load with very little stretching. Strain, or elongation at break, is expressed as a percentage.

- Why it Matters: For reinforcement to be effective, the geogrid must engage and resist load before the soil or liner deforms excessively. A geogrid with low modulus (and high elongation) would stretch like a rubber band, allowing the liner to deform dangerously before the grid takes up the load. Look for geogrids with low elongation (typically under 5%, often below 3%). This indicates a high modulus and ensures the geogrid provides immediate, effective reinforcement.

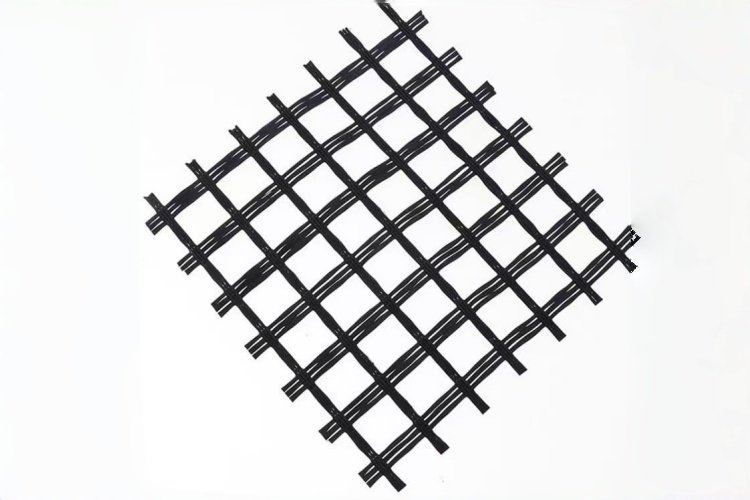

Junction Strength and Aperture Stability

A geogrid is a system of ribs and junctions. Its performance depends on how well these components work together.

- Definition: Junction strength measures the force required to pull a rib out of its junction. Aperture stability refers to the ability of the grid openings (the apertures) to maintain their shape under load. Aperture size itself is also a key parameter, with common dimensions for landfill applications ranging from 25 mm x 25 mm to 40 mm x 40 mm.

- Why it Matters: Strong junctions are essential for transferring stress from the soil, through the ribs, and across the entire grid. If junctions are weak, the grid can essentially fall apart under load. The aperture size and stability are critical for soil-geogrid interaction. The apertures must be large enough to allow soil or aggregate particles to strike through and interlock, but stable enough not to deform, which would reduce this interlocking mechanism.

Long-Term Performance Specifications

Landfills are designed to last for many decades. A geogrid's short-term strength is irrelevant if it cannot sustain loads for 30, 50, or even 100 years.

Creep Resistance under Sustained Loads

This is arguably the most critical long-term specification for a geogrid in a landfill.

- Definition: Creep is the slow, continuous elongation of a material under a constant, sustained load. A geogrid holding back a slope is under a constant load 24/7 for its entire service life.

- Why it Matters: If a geogrid creeps excessively, it will slowly stretch over time, allowing the slope to deform and potentially fail, even if the load never exceeds the geogrid's short-term tensile strength. Different polymers have vastly different creep behaviors. Polyester (PET) and Glass Fiber geogrids exhibit very low creep. High-Density Polyethylene (HDPE) and Polypropylene (PP) geogrids have higher creep potential that must be accounted for in the design. A geogrid specified for primary reinforcement in a landfill should have very low long-term creep, often specified as not to exceed 3% strain over the design life.

Design Strength and Reduction Factors

The strength value on a data sheet is the ultimate tensile strength, not the strength you can actually use in your design calculations. The engineer must determine the Long-Term Design Strength (LTDS) by applying a series of reduction factors (RF) to account for real-world conditions.

LTDS = Ultimate Tensile Strength / (RF_ID x RF_CR x RF_D)

- RF_ID (Installation Damage): Accounts for damage during construction (e.g., from aggregate placement).

- RF_CR (Creep): Accounts for the loss of strength due to long-term sustained load.

- RF_D (Durability): Accounts for degradation from chemical and biological exposure.

For a landfill, these factors can significantly reduce the usable strength. For example, a geogrid with a 100 kN/m ultimate strength might only have an LTDS of 40-50 kN/m after applying the appropriate reduction factors. Always demand reduction factor data from the manufacturer.

Durability and Environmental Resistance

A landfill is one of the most chemically aggressive environments for a construction material. The geogrid's polymer must be able to survive decades of exposure.

Chemical Resistance to Leachate

Leachate can have a wide pH range and contain a cocktail of organic and inorganic chemicals. The geogrid material must be fundamentally inert to this chemical attack. HDPE and PP offer excellent broad-spectrum chemical resistance. PET is also highly resistant but can be susceptible to hydrolysis in very high or low pH environments, which must be considered.

Oxidation and Thermal Aging Resistance

The geogrid polymer will be exposed to oxygen and elevated temperatures within the landfill mass. Over time, this causes oxidation, which makes the polymer brittle. Reputable manufacturers add a robust package of antioxidants and thermal stabilizers to the polymer resin to ensure it can resist degradation for its entire design life.

Biological and Microbial Resistance

The polymers used in geogrids (HDPE, PP, PET) are not a food source for bacteria and fungi commonly found in soil and waste. This ensures the geogrid will not be compromised by microbial degradation.

Interface and Interaction Properties

In a multi-layered liner system, preventing one layer from sliding against another is critical for stability.

Interface Shear Behavior

- Definition: This property defines the frictional characteristics between the geogrid and an adjacent material (geomembrane, GCL, soil, etc.). It is measured in a lab using a large-scale direct shear test (ASTM D5321) and is expressed as an interface friction angle or an efficiency coefficient.

- Why it Matters: A low friction angle between a geogrid and a smooth geomembrane could create a slip surface, leading to slope failure. The geogrid's three-dimensional structure and texture are designed to create a high degree of interaction and friction with other geosynthetics and soil. When designing a slope, the interface shear strength is a primary input for stability calculations. Always obtain specific test data for the exact combination of materials you plan to use.

Testing Standards and Certification Requirements

To ensure you are getting a quality product that meets your specifications, always demand proper documentation.

- Relevant Standards: Look for products tested according to established international standards. Key examples include:

- ASTM D4595: Wide-Width Tensile Properties of Geotextiles.

- ASTM D5262: Test Method for Evaluating the Unconfined Creep Behavior of Geosynthetics.

- ASTM D5321: Test Method for Determining the Shear Strength of Soil-Geosynthetic and Geosynthetic-Geosynthetic Interfaces.

- ISO 10319: Wide-width tensile test.

- Manufacturer Documentation: A reputable manufacturer will provide a full Manufacturer's Quality Control (MQC) report for every roll or lot delivered to your site. This document provides traceability and certifies that the material meets the published specifications. Do not accept material without it.

Performance-Based Specification Approach

The ultimate goal is not to find a product that checks the most boxes, but one that provides the required performance for your specific project at an optimized cost. This means:

- Avoiding Under-Specification: Choosing a geogrid that is too weak or lacks the necessary long-term durability is a direct path to failure.

- Avoiding Over-Specification: Choosing a geogrid that is far stronger than required does not add a proportional amount of safety and unnecessarily increases project costs.

The process involves a geotechnical engineer calculating the required LTDS and interface shear strength for the project, and then selecting a commercially available geogrid that meets these performance requirements after all reduction factors are applied.

Conclusion

Selecting the right geogrid for a landfill liner system is a critical engineering decision that goes far beyond a simple strength comparison. It requires a thorough evaluation of the material's mechanical properties, its long-term performance under sustained load, its chemical and biological durability, and its interaction with other system components. By understanding what specifications like tensile modulus, creep resistance, and interface shear strength truly mean, you can confidently choose a product that will ensure the structural integrity and safety of your containment facility for its entire service life.

Now that you understand the key specifications to look for, the next step is to apply this knowledge to specific landfill scenarios. For guidance on selecting the right type of geogrid for different applications, such as steep slopes versus base reinforcement, we recommend consulting a qualified geotechnical engineer or reviewing detailed design guides.